Technology for purifying and reusing beneficiation wastewater of lead-zinc sulfide ore by coupling of hydrodynamic cavitation and H2O2

A hydraulic cavitation and H2O2 technology, applied in mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of large investment, pungent special smell, and difficulty in industrialization and application of ozone generators , to achieve the effect of low processing cost, wide range of PH value and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

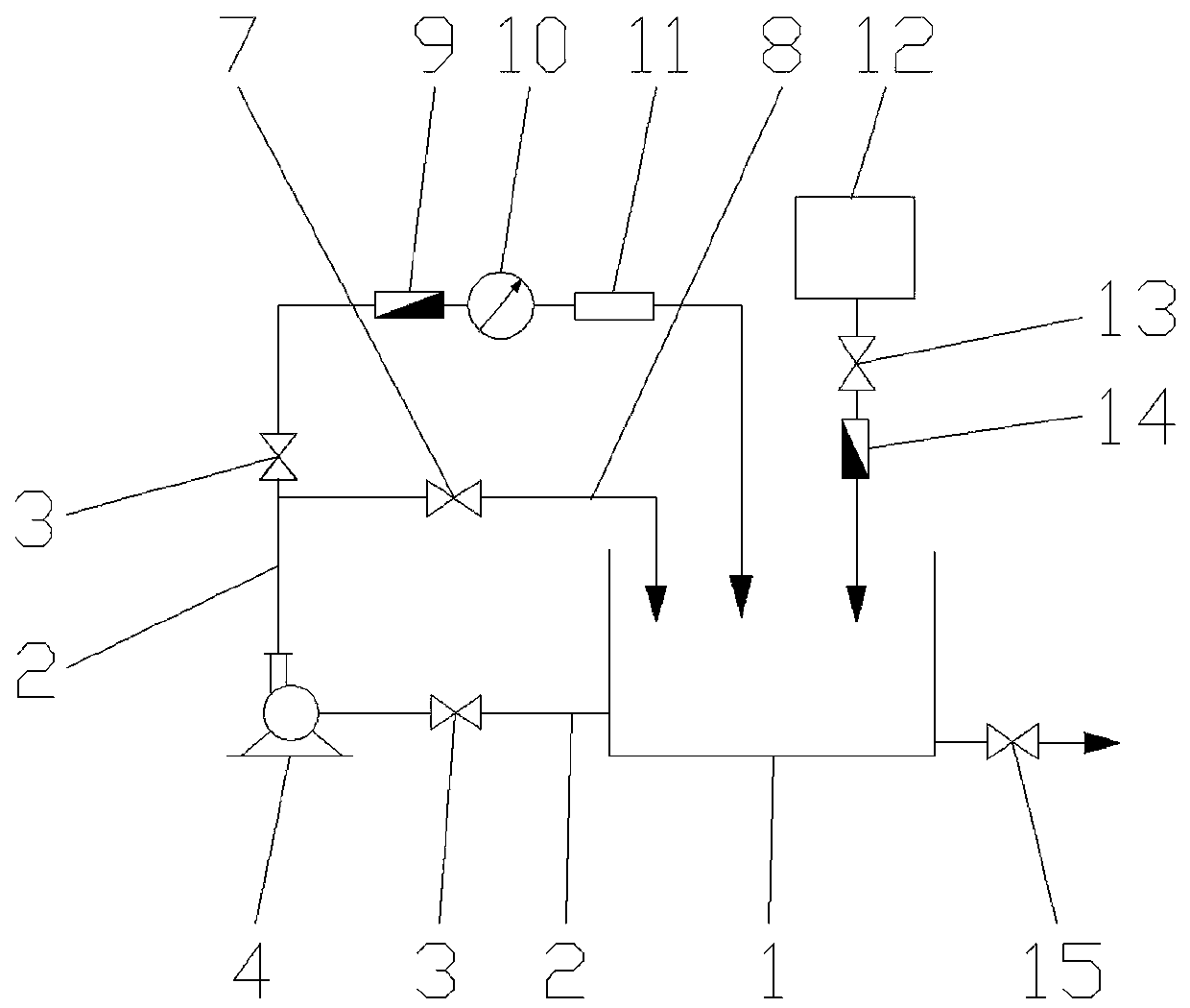

Method used

Image

Examples

Embodiment 1

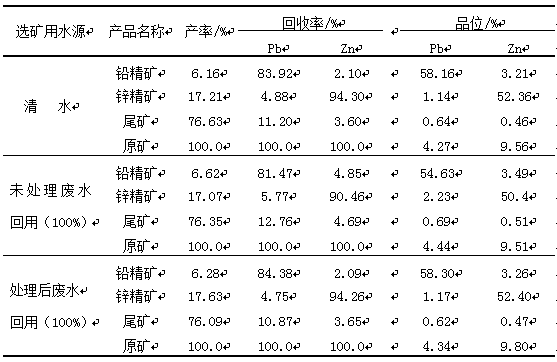

[0031] Embodiment 1: The test wastewater is a comprehensive sample composed of lead concentrate wastewater, zinc concentrate wastewater, mixed concentrate wastewater and zinc tailings overflow water. The total volume of wastewater is 250L, and the water temperature is 23°C; the flow rate of the main pipeline during treatment is 2.82L / the s -1 , the inlet pressure of the cavitator in the main pipeline is 0.43Mpa, the industrial grade (27.5%) hydrogen peroxide is added dropwise through a separatory funnel, and the duration of the drop is 15min. The characteristics of the test results of mixed wastewater water quality indicators for different periods of time are shown in Table 1.

[0032] Table 1 Test results of water quality of mixed wastewater with cyclic treatment for different durations

[0033]

[0034] Note: 1. Determination conditions of foaming property: 1L graduated cylinder, 500mL water sample, air filling volume is 1.67L / min; 2. The foaming property of clear water...

Embodiment 2

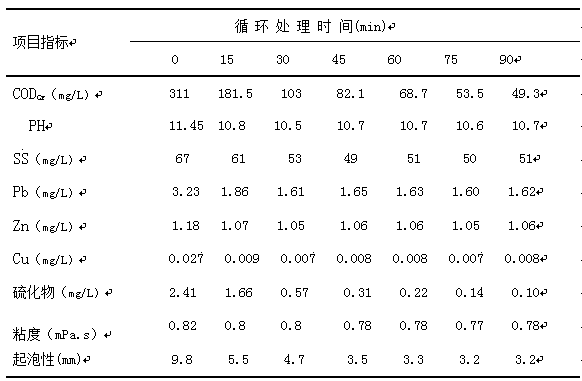

[0037] Embodiment 2: The test wastewater is a comprehensive sample composed of sulfur fine wastewater, sulfur tailing wastewater, mixed concentrate wastewater, tailings overflow water and sewer water. The total volume of wastewater is 300L, and the water temperature is 23°C; the flow rate of the main pipeline during treatment is 3.05 L / s -1 , the inlet pressure of the cavitator in the main pipeline is 0.46Mpa, the industrial grade (27.5%) hydrogen peroxide is added dropwise through a separatory funnel, and the duration of the drop is 20min. The characteristics of the test results of the water quality indicators of the mixed wastewater treated at different times are shown in Table 2.

[0038] Table 2 Test results of water quality of mixed wastewater with continuous treatment in different time periods

[0039]

[0040] Note: 1. Determination conditions of foaming property: 1L graduated cylinder, 500mL water sample, air filling volume is 1.67L / min; 2. The foaming property of ...

Embodiment 3

[0043] Example 3: The test wastewater is a comprehensive sample composed of lead concentrate wastewater, zinc concentrate wastewater, sulfur concentrate wastewater, sulfur tail wastewater, mixed concentrate wastewater and zinc tailings overflow water. The water temperature is 23°C; The flow rate of the main pipeline during processing is 2.93L / s -1 , the inlet pressure of the cavitator in the main pipeline is 0.45Mpa, the industrial grade (27.5%) hydrogen peroxide is added dropwise through a separatory funnel, and the characteristics of the water quality index test results of the mixed wastewater treated with different hydrogen peroxide additions during cavitation are shown in Table 3.

[0044] Table 3 Different H 2 o 2 Test results of water quality indicators of mixed wastewater at the time of consumption

[0045]

[0046] Note: 1. Determination conditions of foaming property: 1L graduated cylinder, 500mL water sample, air filling volume is 1.67L / min; 2. The foaming prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com