Cosmetic bristle, preparation method of cosmetic bristle and cosmetic brush

A technology of oxidizing agent and polylactic acid is applied in the fields of cosmetic silk, its preparation, and cosmetic brushes, and can solve the problems of difficulty in forming cosmetic silk, pollution, and low degree of degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of cosmetic silk, comprising the following steps:

[0056] a) mixing polylactic acid, nylon and polytetramethylene terephthalate to obtain a mixture;

[0057] b) melt-blending the mixture with a plasticizer, a stabilizer, an oxidizing agent, a fixed filler and a filler to obtain a melt;

[0058] c) Drawing, shaping and post-processing the molten material to obtain makeup silk.

[0059] Wherein, the types, dosages and sources of polylactic acid, nylon, polytetramethylene terephthalate, plasticizer, stabilizer, oxidant, fixed filler and filler are all consistent with those described in the above technical solution , which will not be repeated here.

[0060] In the present invention, in the step a), the mixing preferably further includes grinding, through which the polylactic acid, nylon and polytetramethylene terephthalate are ground into powder. The grinding method is not particularly limited, and the grinding m...

Embodiment 1

[0073] 1.1 Sample preparation

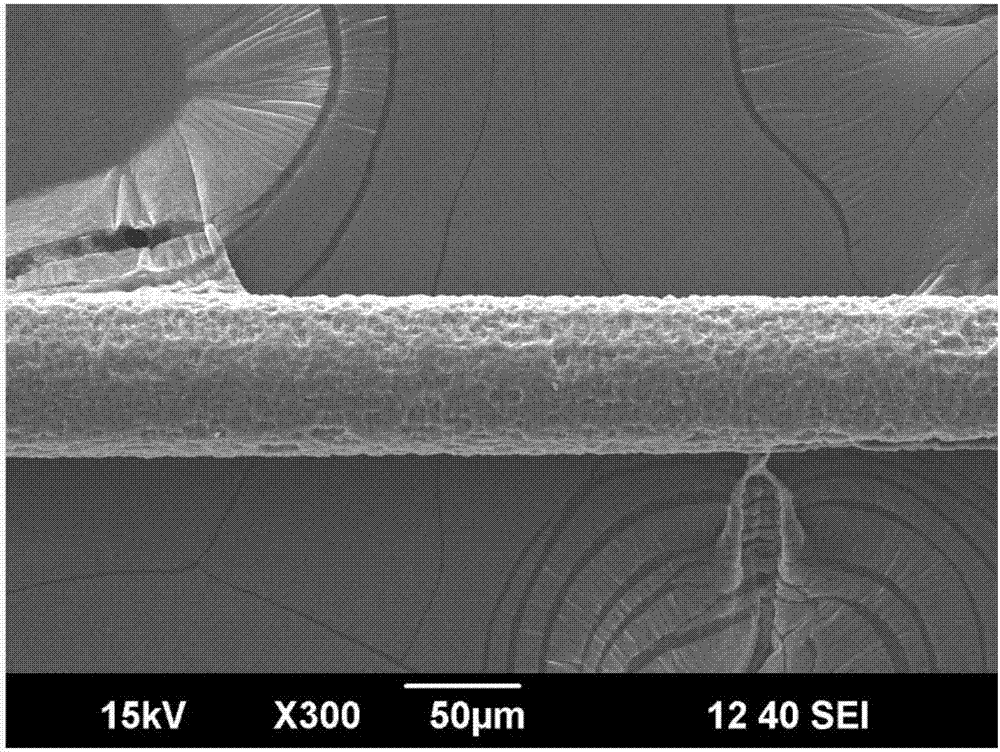

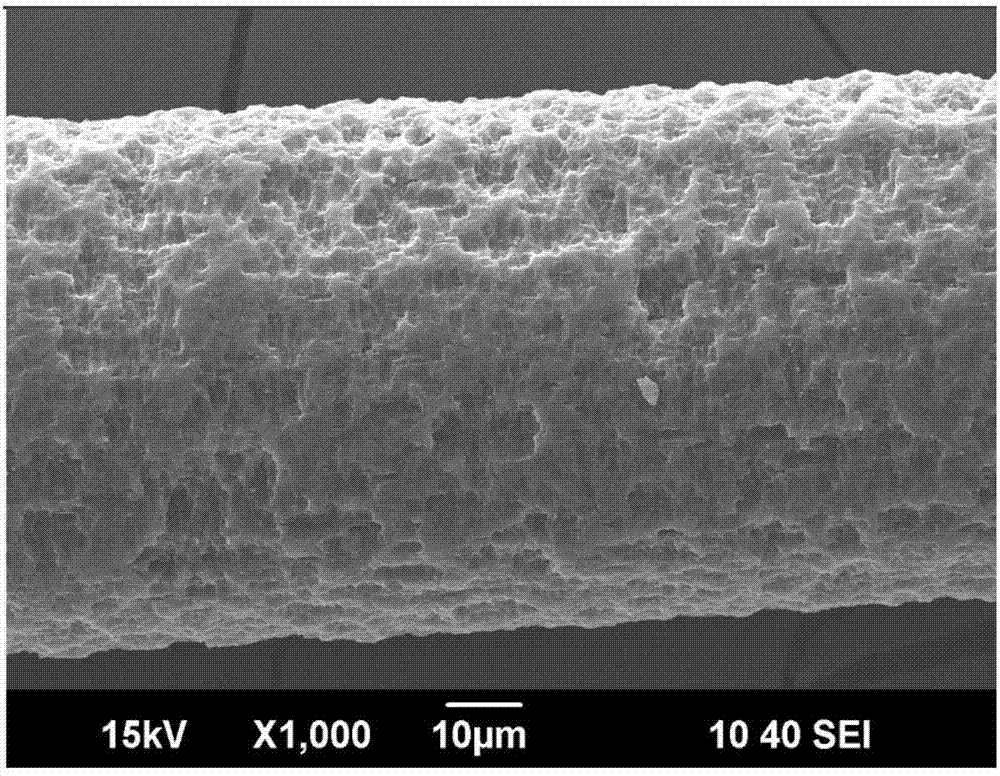

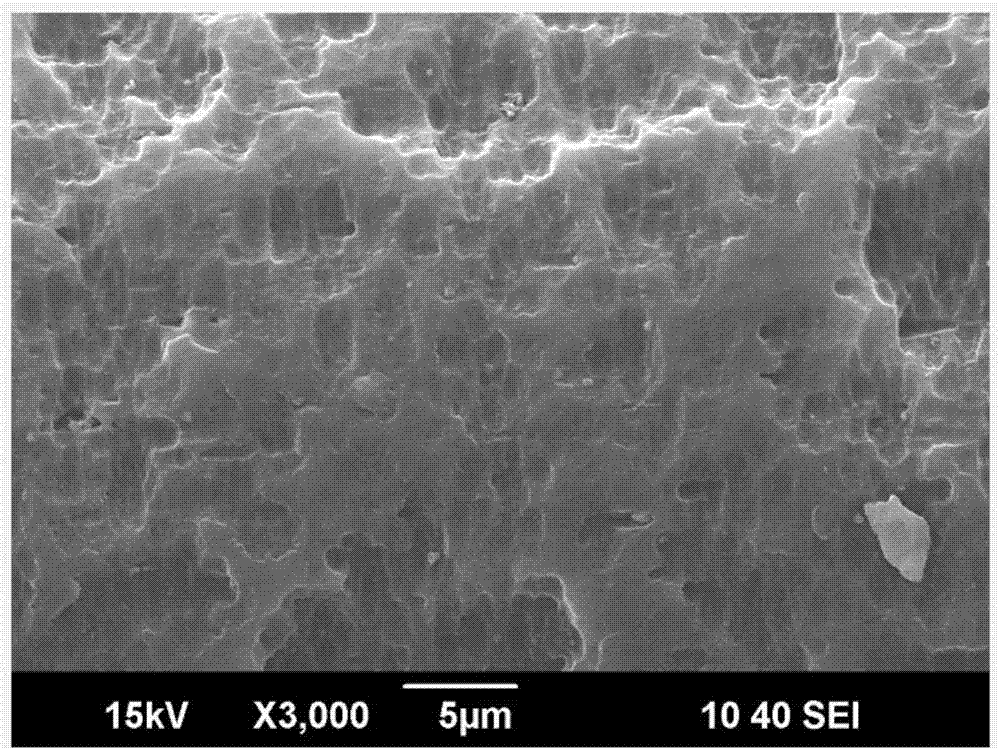

[0074] Mix and grind 60% polylactic acid, 20% PA6 and 20% PBT to obtain a powder with a particle size of 1000-1500 mesh, and bake at 115° C. for 2.5 hours to obtain a mixture. Based on the sum of the quality of the above three raw materials, add 2% epoxidized soybean oil, 5% lead stearate, 5% tin oxide, 3% sodium hydroxide and 3% polyethylene. After 3 h of melt blending, a melt was obtained. Put the molten material into the cosmetic silk production line, extrude and draw to obtain a monofilament with a diameter of 0.03-0.12mm, and then soak it in water for 3 minutes at a water temperature of 25°C to obtain a cooled and formed monofilament. After mechanical trimming, trimmed Monofilament: place the trimmed monofilament in an aqueous sodium hydroxide solution with a mass concentration of 9%, and oxidize it at 100°C for 25 minutes to obtain an oxidized monofilament; then wash, dry and arrange it with clean water to obtain a cosmetic silk.

[0075...

Embodiment 2

[0089] 1.1 Sample preparation

[0090] Mix and grind 55% polylactic acid, 24% PA6 and 21% PBT to obtain a powder with a particle size of 1000-1500 mesh, and bake at 120°C for 2 hours to obtain a mixture. Based on the sum of the quality of the above three raw materials, add 3% epoxy butyl furfurate, 5% barium cinnamate, 5% titanium dioxide, 3% barium sulfate and 3% polypropylene, at 245 ° C After 3 h of melt blending, a melt was obtained. The melted material is put into the cosmetic silk production line, extruded and drawn to obtain monofilaments with a diameter of 0.03-0.12 mm, and then soaked in water for 3 minutes at a water temperature of 30 ° C to obtain cooled and formed monofilaments. After mechanical trimming, trimmed Monofilament: place the trimmed monofilament in an aqueous sodium hydroxide solution with a mass concentration of 9%, and oxidize it at 120°C for 25 minutes to obtain an oxidized monofilament; then wash, dry and arrange it with clean water to obtain a cos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com