Preparation method of low temperature-resistant modified asphalt waterproof coil

A technology of modified asphalt and waterproof membrane, which is applied in the direction of textiles, papermaking, fiber treatment, etc. It can solve the problems of poor tensile performance, cracking, poor adhesion, etc., and achieve the purpose of inhibiting the hardening of asphalt crystals and improving fluidity , The effect of improving low temperature adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

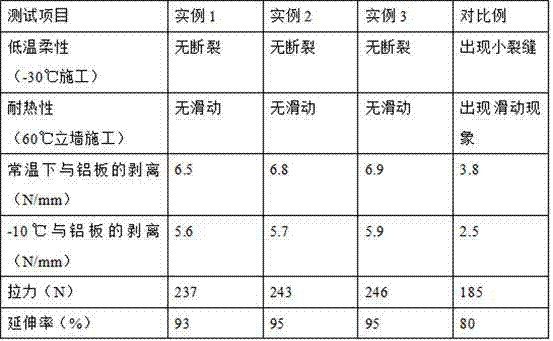

Examples

example 1

[0025]Put the SBS rubber into the impact crusher and crush it for 30 minutes to obtain broken rubber blocks. Send the crushed rubber blocks into the liquid nitrogen freezing device, freeze to -50°C, and freeze for 3 hours. Take out the frozen broken rubber blocks and put them into crushed Grinding in the machine to obtain SBS rubber powder; according to parts by weight, put 40 parts of petroleum asphalt and 10 parts of Buton rock asphalt in a stirring tank, heat up to 90°C, keep stirring at a speed of 200r / min for 20min, and then Add SBS rubber powder into the stirring tank, and continue stirring for 40 minutes to obtain SBS-dispersed asphalt; put 300g of SBS-dispersed asphalt into the oil bath, heat up to 200°C, and keep warm for 10 minutes, then add 100mL of mineral base to the oil bath Oil, stir and mix at a low speed of 500r / min for 30min, and then emulsify at a high speed of 4000r / min to obtain rubber powder modified asphalt; add 60g polypropylene masterbatch and 80g Fly ...

example 2

[0027] Put the SBS rubber into the impact crusher and crush it for 37 minutes to obtain broken rubber pieces. Send the broken rubber pieces into the liquid nitrogen freezing device, freeze to -45°C, and freeze for 3.5 hours. Take out the frozen broken rubber pieces and put them in Pulverize in a pulverizer to obtain SBS rubber powder; in parts by weight, put 45 parts of petroleum asphalt and 13 parts of Buton rock asphalt in a stirring tank, heat up to 95°C, keep stirring at a speed of 250r / min for 25min, Then add SBS rubber powder into the stirring tank, and continue stirring for 45 minutes to obtain SBS-dispersed asphalt; put 350g of SBS-dispersed asphalt into the oil bath, heat up to 210°C, and keep it warm for 13 minutes, then add 110mL of minerals to the oil bath The base oil was stirred and mixed at a low speed of 550r / min for 33 minutes, and then emulsified at a high speed of 4100r / min to obtain rubber powder modified asphalt; 65g of polypropylene masterbatch and 83g of...

example 3

[0029] Put the SBS rubber into the impact crusher and crush it for 45 minutes to get the crushed rubber block, send the crushed rubber block into the liquid nitrogen freezing device, freeze to -40°C, freeze for 4 hours, take out the frozen crushed rubber block, put it into the crushed Grinding in the machine to obtain SBS rubber powder; according to parts by weight, put 50 parts of petroleum asphalt and 15 parts of Buton rock asphalt in a stirring tank, heat up to 100°C, keep stirring at a speed of 300r / min for 30min, and then Add SBS rubber powder into the stirring tank, and continue stirring for 50 minutes to obtain SBS-dispersed asphalt; put 400g of SBS-dispersed asphalt into the oil bath, heat up to 220°C, and keep it warm for 15 minutes, then add 120mL of mineral base to the oil bath Oil, stir and mix at a low speed of 600r / min for 35min, then emulsify at a high speed of 4200r / min to obtain rubber powder modified asphalt; add 70g polypropylene masterbatch and 85g Fly ash,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com