High-strength high-toughness high-hardenability high-speed axle steel and heat treatment method thereof

A high-hardenability, high-strength-toughness technology, applied in the field of railway axle steel, can solve the problems that the effect of improving the hardenability cannot achieve the expected effect, reducing the service performance of the axle, and uneven grain size, etc., to achieve strong and toughness. Improve, improve hardenability, improve the effect of hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the embodiments, and the embodiments of the present invention can be used to illustrate the principle of the present invention.

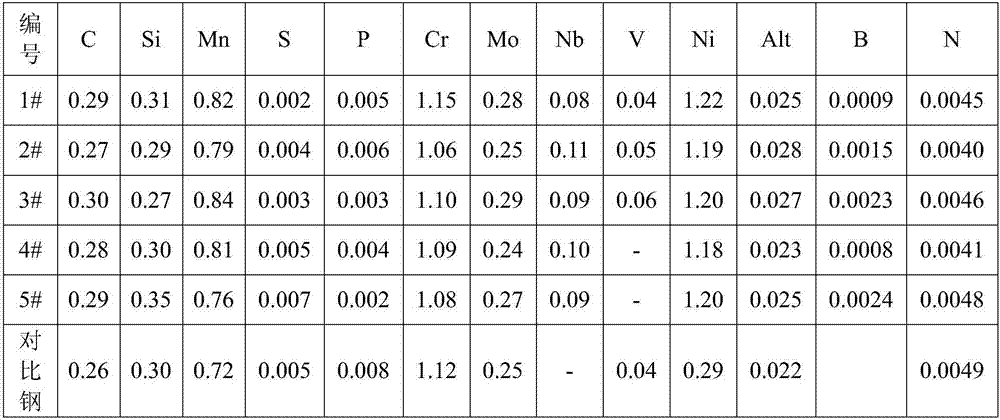

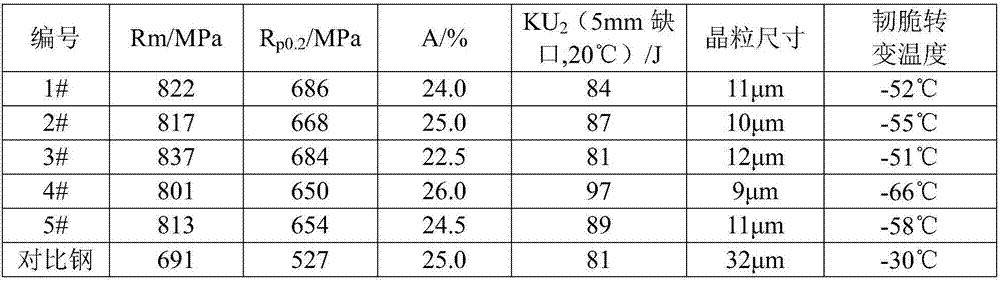

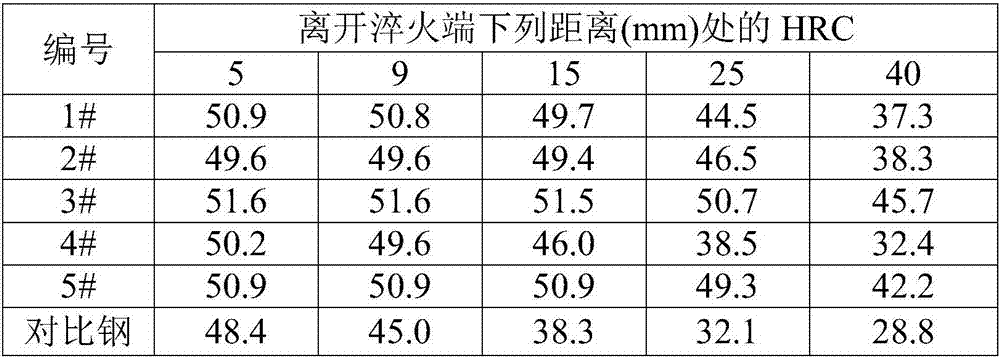

[0040] The invention relates to a high-strength toughness high-hardenability high-speed axle steel, the chemical composition of which contains C, Si, Cr, Mn, V, Nb, B, Ni, Mo, Alt, P, S, O and N, And Fe and unavoidable impurities.

[0041] Preferably, the C content is 0.24 to 0.32wt.%. Carbon is one of the most important strengthening elements and elements that improve hardenability. In order to ensure sufficient strength and hardenability, the C content must be above 0.24wt.%. However, when the C content is higher than 0.32wt.%, the plasticity and toughness of the steel will be significantly reduced.

[0042] Preferably, the content of Si is controlled to a relatively low level of 0.20-0.40wt.%. Si is an alloying element that has a significant solid solution strengthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com