Oxygen-rich side-blowing double-region weld pool smelting furnace

A molten pool smelting furnace and oxygen-enriched technology, which is applied in the field of smelting furnaces, can solve the problems of large hearth area, difficult maintenance and maintenance, partition wall erosion, etc., and achieve the effects of low slag grade, significant energy saving and consumption reduction, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

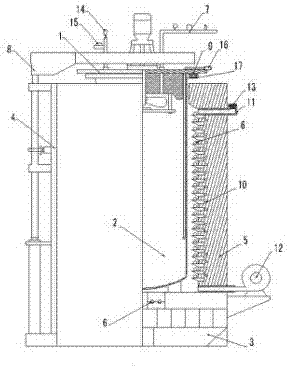

[0009] Depend on figure 1 Known, the present invention a kind of oxygen-enriched side-blown double-zone molten pool smelting furnace, by furnace body 1, furnace door 2, vertical furnace door hinge 2-1, horizontal furnace door hinge 2-2, pin 2-3, gas system 3. Dust removal cover 4, sub-induction air pipe 5, fan 6, main air induction pipe 7, dust removal pool 8, aluminum liquid outlet 9, slag removal device 10, the gas system 3 is installed on the left side of the furnace body 1, two The dust removal cover 4 is installed on the front and rear sides of the body of furnace 1, and the sub-induction duct 5 is installed above the dust removal cover 4 and communicates with the dust removal cover 4. The two sub-induction ducts 5 are finally brought together with the main induction duct 7 Connected, the main air duct 7 is finally connected to the dust removal pool 8, the molten aluminum outlet 9 is set at the lower middle of one side of the furnace body 1, and the slag removal device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com