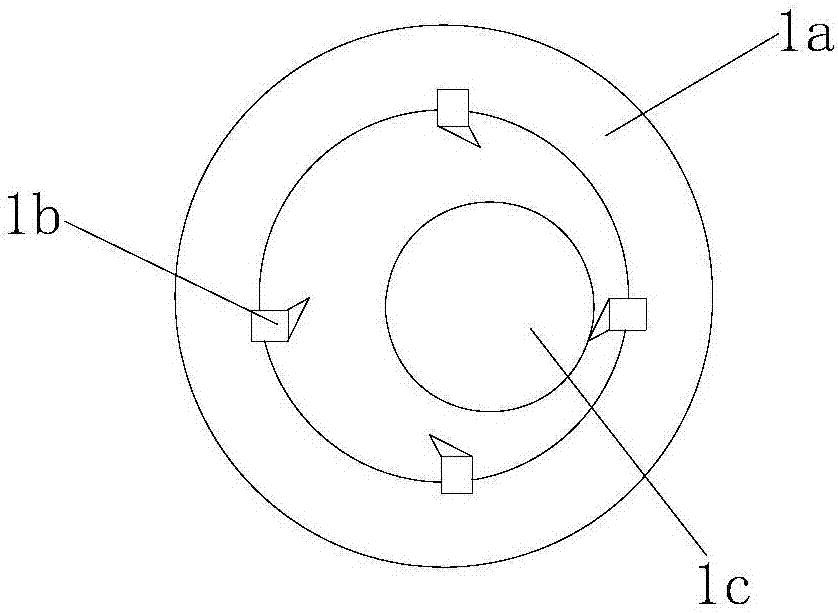

Temperature prediction method applied to lead screw whirling-cutter milling machining region

A technology of processing area and prediction method, applied in the field of mechanical processing, can solve the problems of temperature prediction in the processing area of screw whirling milling, and achieve the effect of optimizing integrity and optimizing tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The lead screw is cut and processed by an 8-meter CNC whirlwind milling machine. The cutting tool is made of PCBN material. tool is 0.044W / (m℃); AISI 52100 bearing steel screw material is used, the density is 7.81g / cm3, and the thermal diffusivity is a chip 0.126J / (g℃), thermal conductivity λ chip It is 0.466W / (m°C). The cutting force F required in this model is obtained by the Kistler three-way piezoelectric cutting measuring instrument; the experimental instrument required for the verification of the temperature model is a non-contact infrared camera provided by FLIR. The specific parameters of the experimental processing are shown in the table below:

[0039]

[0040] A temperature prediction method for the processing area of screw whirl milling, comprising the following steps:

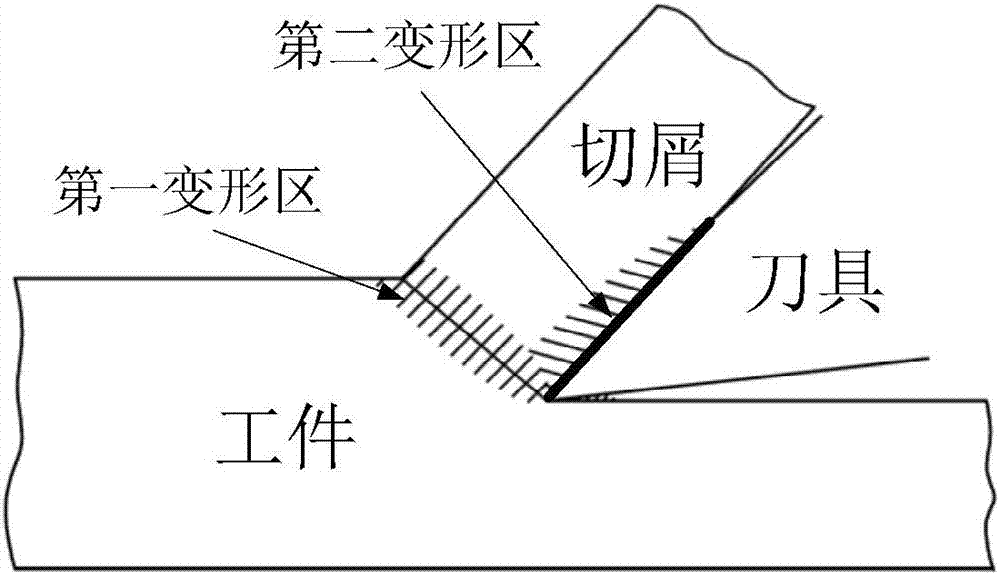

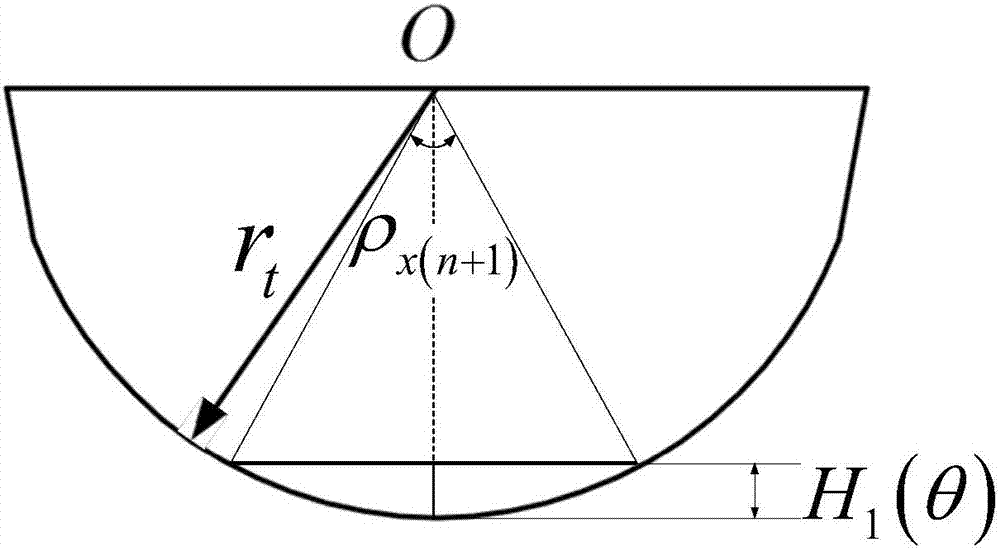

[0041] Step 1: Establish the first-stage transient undeformed chip thickness model H of the cutting process respectively 1 (θ), the first stage transient undeformed chip width model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com