Whitened red phosphorus with high flame-retardant efficiency and preparation method of whitened red phosphorus

A high-efficiency, red phosphorus technology, applied in chemical instruments and methods, compositions for inhibiting chemical changes, etc., can solve the problems of easy moisture absorption, high production cost, easy oxidation, etc., and achieve high flame retardant efficiency and oxidation resistance. Good, small addition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

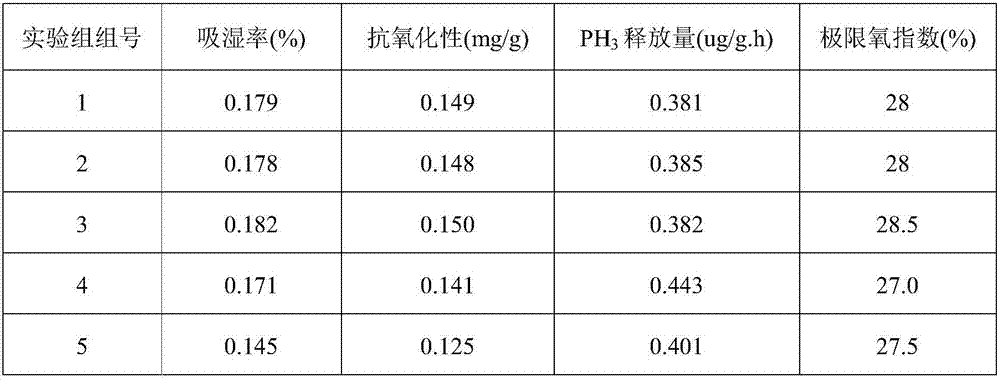

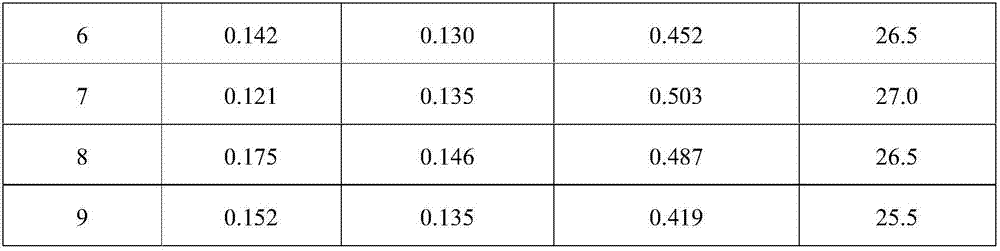

Examples

preparation example Construction

[0023] The preparation method of the whiteness red phosphorus with high flame retardant efficiency provided by the embodiments of the present invention comprises:

[0024] (1) adding into water and accounting for water quality is 1% penetrating agent and emulsifier to form the first solution, adding and accounting for water quality is 50~80% red phosphorus and accounting for red phosphorus quality is 40%~80% in the first solution % aluminum salt to form a second solution, and the second solution was heated to 90° C. to prepare an emulsified dispersion system of red phosphorus and aluminum salt.

[0025] Among them, as preferably, the penetrating agent includes fatty alcohol polyoxyethylene ether; fatty alcohol polyoxyethylene ether is the most important type of nonionic surfactant, and the ether bond in its molecule is not easy to be destroyed by acid and alkali, so the stability Higher, better water solubility, electrolyte resistance, easy biodegradation, small foam; emulsifi...

Embodiment 1

[0039] This embodiment provides a preparation method of whiteness red phosphorus with high flame retardant efficiency, comprising the following preparation steps:

[0040] (1) Take 300ml of water in a 2L three-necked flask, add 2g of fatty alcohol polyoxyethylene ether and 1g of sodium dodecylbenzenesulfonate to it, disperse at high speed and add 150g of red phosphorus and 60g of aluminum chloride, heated to 90°C to obtain an emulsified dispersion system of red phosphorus and aluminum chloride;

[0041] (2) Keep 90°C and shear dispersion, and dissolve 78g of sodium hypophosphite in 200g of water to form a sodium hypophosphite solution, slowly drop the formed sodium hypophosphite solution into the emulsified dispersion system for 2 hours to react to form a third solution, and Obtain the first layer of AHP-coated red phosphorus;

[0042] (3) solution is cooled to 50 ℃, and the aluminum sulfate octadecahydrate of 225g is added in water and form concentration is the aluminum sulf...

Embodiment 2

[0046] This embodiment provides a preparation method of whiteness red phosphorus with high flame retardant efficiency, comprising the following preparation steps:

[0047] (1) Take 300ml of water in a 2L three-necked flask, add 1g of fatty alcohol polyoxyethylene ether and 2g of sodium dodecylbenzenesulfonate to it, disperse at high speed and add 240g of red phosphorus and 192g of aluminum chloride, heated to 90°C to obtain an emulsified dispersion system of red phosphorus and aluminum chloride;

[0048] (2) Keep 90°C and shear dispersion, and dissolve 288g of sodium hypophosphite in 400g of water to form a sodium hypophosphite solution, slowly drop the resulting sodium hypophosphite solution into the emulsified dispersion system and react for 2h to form a third solution, and Obtain the first layer of AHP-coated red phosphorus;

[0049] (3) solution is cooled to 50 ℃, and the aluminum sulfate octadecahydrate of 816g is added in water and form concentration is the aluminum sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com