Polyurethane-fluorocarbon composite powder coating suitable for humid and hot marine climatic environment and preparation method of polyurethane-fluorocarbon composite powder coating

A marine climate, powder coating technology, used in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve problems such as poor adhesion, large technical risks, poor pigment wetting, etc., to achieve long service life, comprehensive Low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

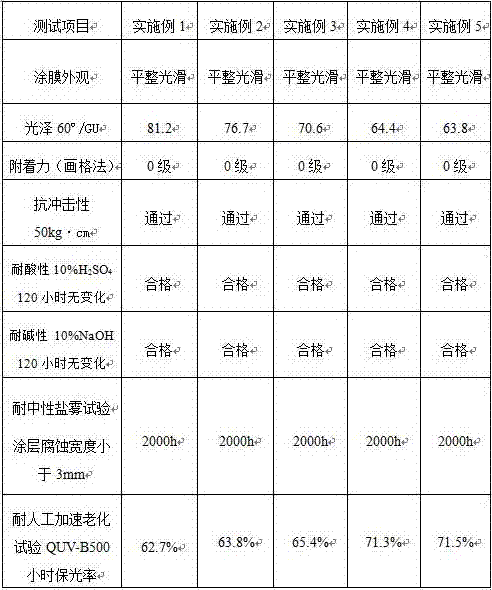

Examples

Embodiment 1

[0032] The composition and weight ratio of a polyurethane-fluorocarbon composite powder coating suitable for hot and humid marine climate provided by this example are: 160 parts of polyurethane resin with a hydroxyl value of 35-42 mgKOH / g, and a hydroxyl value of 30-42 mgKOH / g. 40 parts of 40mgKOH / g FEVE type fluorocarbon resin, 50 parts of self-blocking isocyanate resin, 0.5 parts of dibutyltin dilaurate, 50 parts of titanium dioxide, 30 parts of barium sulfate, 1.0 parts of silica adsorption type acrylate leveling agent, 0.5 part of benzoin, 3 parts of pigment.

[0033] The preparation method comprises the following steps:

[0034] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0035] (b) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 100°C;

[0036] (c) The extruded material is compressed into tablets, cooled, and pulverized...

Embodiment 2

[0038] The components and weight ratios of a polyurethane-fluorocarbon composite powder coating suitable for hot and humid marine climate provided by this example are: 140 parts of polyurethane resin with a hydroxyl value of 35-42 mgKOH / g, and a hydroxyl value of 30-42 mgKOH / g. 40mgKOH / g 60 parts of FEVE type fluorocarbon resin, 40 parts of self-blocking isocyanate resin, 0.5 part of dibutyltin dilaurate, 50 parts of titanium dioxide, 30 parts of barium sulfate, 1.0 part of polyester resin loaded acrylate leveling agent, 0.5 part of benzoin, 3 parts of pigment.

[0039] The preparation method comprises the following steps:

[0040] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 10 minutes;

[0041] (b) The crushed material is extruded into a twin or single screw extruder; the heating temperature of the extruder is controlled at 100°C;

[0042] (c) The extruded material is compressed into tablets, cooled, and pulveri...

Embodiment 3

[0044] The components and weight ratio of a polyurethane-fluorocarbon composite powder coating suitable for hot and humid marine climate provided by this example are: 120 parts of polyurethane resin with a hydroxyl value of 35-42 mgKOH / g, and a hydroxyl value of 30-42 mgKOH / g. 40mgKOH / g 80 parts of FEVE type fluorocarbon resin, 60 parts of external blocking agent type isocyanate resin, 0.5 parts of dibutyltin dilaurate, 50 parts of titanium dioxide, 30 parts of barium sulfate, 1.0 parts of silica adsorption type acrylate leveling agent, 0.5 part of benzoin, 3 parts of pigment.

[0045] The preparation method comprises the following steps:

[0046] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0047] (b) The crushed material is extruded into a twin or single screw extruder; the heating temperature of the extruder is controlled at 100°C;

[0048] (c) The extruded material is compressed into tablets, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com