Preparation method for metal deactivator applied to catalytic cracking, and metal deactivator prepared by using same

A metal passivator, catalytic cracking technology, applied in catalytic cracking, catalyst protection, chemical instruments and methods, etc., can solve problems such as poor product stability, complex process, time-consuming and energy-consuming, and achieve low cost and simple preparation process. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

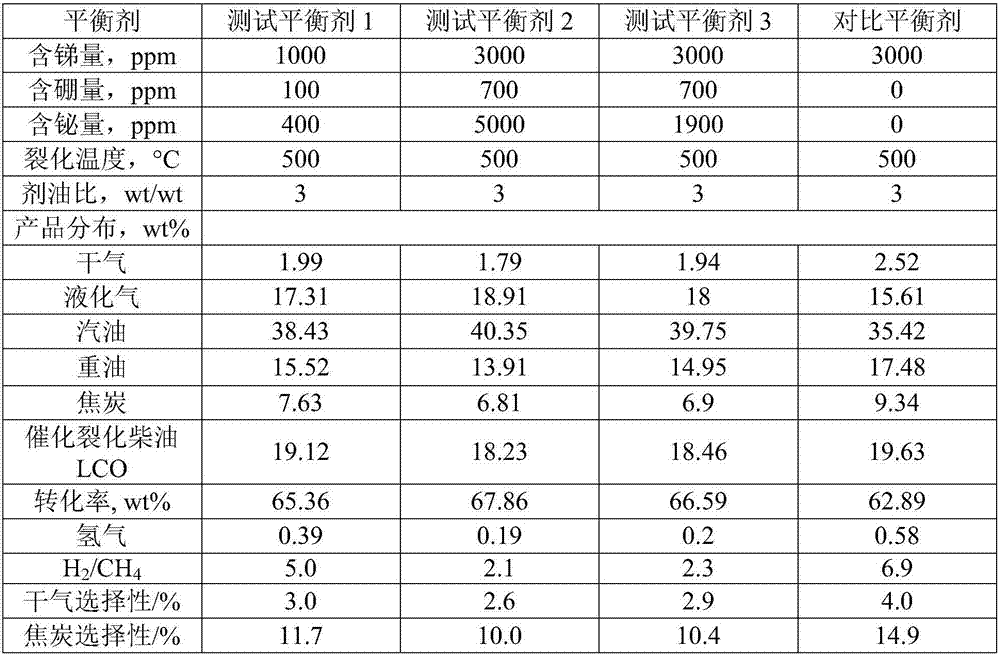

Examples

preparation example Construction

[0017] The first aspect of the present invention: provide a kind of preparation method of catalytic cracking metal deactivator, this method comprises: a, antimony trioxide, hydroxycarboxylic acid, boron-containing compound, bismuth-containing compound, pH adjuster and water are mixed, React for 30-60 minutes at a temperature of 20-90°C to obtain the first product, wherein the mass ratio of antimony trioxide, hydroxycarboxylic acid, boron-containing compound, bismuth-containing compound, pH regulator and water Is 1: (2-4): (0.5-1.2): (0.4-2): (0.6-1.2): (2-10); b, the oxidant is mixed with the first product obtained in step a, and the The catalytic cracking metal passivator is obtained by reacting in a closed container at a temperature of 100-150° C. for 1-2 hours, wherein the mass ratio of the oxidant to antimony trioxide is (0.4-1.1):1. It should be noted that, since the catalytic cracking metal passivator prepared by the method of the present invention is generally used in t...

Embodiment 1

[0028] Add 1.8kg diethanolamine, 6kg tartaric acid, 3kg antimony trioxide, 1.2kg bismuth oxide, 1.5kg boric acid and 30kg deionized water into the reaction kettle, stir at room temperature for 30 minutes, add 2kg 30% by mass of hydrogen peroxide dropwise, and finish adding Finally, the reaction kettle was sealed and heated to 100° C. for 1 hour, and then cooled out of the kettle to obtain a catalytic cracking metal passivator. The product was clear and transparent, and the pH value was 7.1.

Embodiment 2

[0030] Add 2.4kg ethanolamine, 8kg citric acid, 2kg antimony trioxide, 4kg bismuth hydroxide, 2.4kg boric acid and 4kg deionized water into the reaction kettle, raise the temperature to 90°C and stir for 30 minutes, then add 2.2kg benzyl peroxide dropwise Acyl, after the addition, the reaction vessel was closed and heated to 150°C for 1.5 hours, and then cooled out of the vessel to obtain a catalytic cracking metal passivator. The product was clear and transparent, with a pH value of 8.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com