Silicon carbide modified catalyst used for microwave-heating catalytic oxidization of VOCs and preparation method thereof

A technology of catalytic oxidation and microwave heating, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problem of high complete conversion temperature, improve catalytic activity, facilitate engineering applications, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

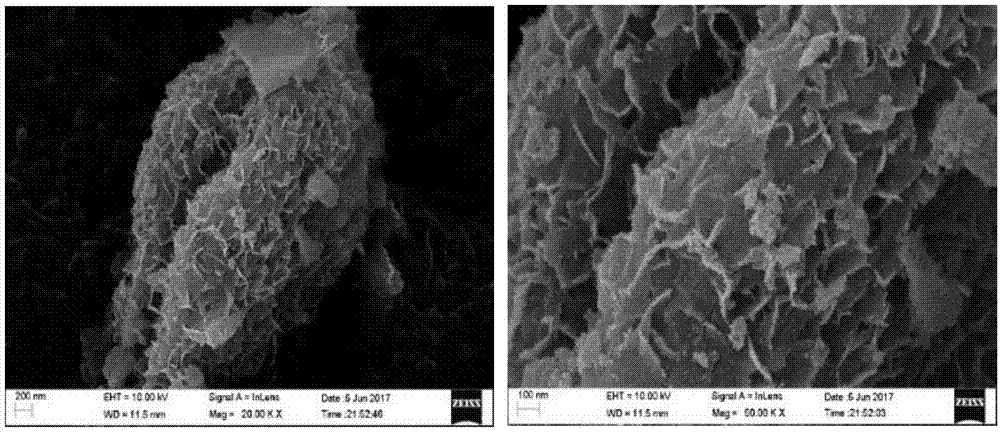

Image

Examples

Embodiment 1

[0041] Weigh 30gAl(NO 3 ) 3 9H 2 O was dissolved in 150ml of deionized water; 0.122g of SiC powder was added to the solution and mixed evenly (calculated based on the silicon carbide doping ratio in the composite carrier being 3%); the mixed solution was placed on a magnetic stirrer and added drop by drop under strong stirring Ammonia water, adjust the pH value to about 10; put the mixed solution in a constant temperature water bath at 60°C for 30 minutes; let the mixed solution stand for 12 hours, remove the supernatant, and dry the lower sediment at 105°C for 24 hours; transfer the dried solid Place in the crucible in a temperature-programmed muffle furnace, control the heating rate of 10°C / min, and roast at the end temperature of 550°C for 1h, and naturally cool to room temperature; the obtained solid can be properly ground to obtain 3% SiC-Al 2 o 3 Composite carrier. 0.9056gCo(NO 3 ) 3 ·6H 2 O and 0.3154gCe(NO 3 ) 3 ·6H 2 O (calculated at 5% Co loading and 2.5% C...

Embodiment 2

[0044] Weigh 30gAl(NO 3 ) 3 9H 2 O was dissolved in an appropriate amount of laboratory-made deionized water, stirred and dissolved; 0.204g of SiC powder was added to the solution and mixed evenly (the doping ratio of silicon carbide in the composite carrier was 5%); the mixed solution was placed on a magnetic stirrer and stirred vigorously. Add ammonia water drop by drop to adjust the pH value to about 10; put the mixed solution in a constant temperature water bath at 60°C for 30 minutes; let the mixed solution stand for 12 hours, remove the supernatant, and dry the lower sediment at 105°C for 24 hours; The final solid was transferred to a crucible and placed in a temperature-programmed muffle furnace, set to raise the temperature to 550° C. for 1 h, and roasted at this temperature for 1 h, and cooled naturally to room temperature. 0.9056gCo(NO 3 ) 3 ·6H 2 O and 0.3154gCe(NO 3 ) 3 ·6H 2 O was dissolved in 50ml deionized water; weigh 5g of the prepared 5% SiC-Al 2 o ...

Embodiment 3

[0047] Weigh 30gAl(NO 3 ) 3 9H 2 O was dissolved in an appropriate amount of laboratory-made deionized water, stirred and dissolved; 0.408g of SiC powder was added to the solution and mixed evenly (the doping ratio of silicon carbide in the composite carrier was 10%); the mixed solution was placed on a magnetic stirrer and stirred vigorously. Add ammonia water drop by drop to adjust the pH value to about 10; put the mixed solution in a constant temperature water bath at 60°C for 30 minutes; let the mixed solution stand for 12 hours, remove the supernatant, and dry the lower sediment at 105°C for 24 hours; The final solid was transferred to a crucible and placed in a temperature-programmed muffle furnace, set to raise the temperature to 550° C. for 1 h, and roasted at this temperature for 1 h, and cooled naturally to room temperature. 0.9056gCo(NO 3 ) 3 ·6H 2 O and 0.3154gCe(NO 3 ) 3 ·6H 2 O was dissolved in 50ml deionized water; weigh 5g of the prepared 5% SiC-Al 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com