A kind of silicon carbide modified catalyst for microwave heating catalytic oxidation VOCs and preparation method thereof

A technology of catalytic oxidation and microwave heating, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problem of high complete conversion temperature, achieve the effects of improving catalytic activity, reducing costs, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

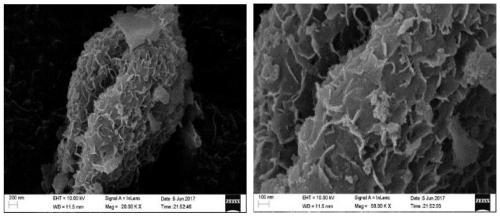

Image

Examples

Embodiment 1

[0041] Weigh 30gAl(NO 3 ) 3 9H 2 O was dissolved in 150ml of deionized water; 0.122g of SiC powder was added to the solution and mixed evenly (calculated based on the silicon carbide doping ratio in the composite carrier being 3%); the mixed solution was placed on a magnetic stirrer and added drop by drop under strong stirring Ammonia water, adjust the pH value to about 10; put the mixed solution in a constant temperature water bath at 60°C for 30 minutes; let the mixed solution stand for 12 hours, remove the supernatant, and dry the lower sediment at 105°C for 24 hours; transfer the dried solid Place in the crucible in a temperature-programmed muffle furnace, control the heating rate of 10°C / min, and roast at the end temperature of 550°C for 1h, and naturally cool to room temperature; the obtained solid can be properly ground to obtain 3% SiC-Al 2 o 3 Composite carrier. 0.9056gCo(NO 3 ) 3 ·6H 2 O and 0.3154gCe(NO 3 ) 3 ·6H 2 O (calculated at 5% Co loading and 2.5% C...

Embodiment 2

[0044] Weigh 30gAl(NO 3 ) 3 9H 2 O was dissolved in an appropriate amount of laboratory-made deionized water, stirred and dissolved; 0.204g of SiC powder was added to the solution and mixed evenly (the doping ratio of silicon carbide in the composite carrier was 5%); the mixed solution was placed on a magnetic stirrer and stirred vigorously. Add ammonia water drop by drop to adjust the pH value to about 10; put the mixed solution in a constant temperature water bath at 60°C for 30 minutes; let the mixed solution stand for 12 hours, remove the supernatant, and dry the lower sediment at 105°C for 24 hours; The final solid was transferred to a crucible and placed in a temperature-programmed muffle furnace, set to raise the temperature to 550° C. for 1 h, and roasted at this temperature for 1 h, and cooled naturally to room temperature. 0.9056gCo(NO 3 ) 3 ·6H 2 O and 0.3154gCe(NO 3 ) 3 ·6H 2 O was dissolved in 50ml deionized water; weigh 5g of the prepared 5% SiC-Al 2 o ...

Embodiment 3

[0047] Weigh 30gAl(NO 3 ) 3 9H 2 O was dissolved in an appropriate amount of laboratory-made deionized water, stirred and dissolved; 0.408g of SiC powder was added to the solution and mixed evenly (the doping ratio of silicon carbide in the composite carrier was 10%); the mixed solution was placed on a magnetic stirrer and stirred vigorously. Add ammonia water drop by drop to adjust the pH value to about 10; put the mixed solution in a constant temperature water bath at 60°C for 30 minutes; let the mixed solution stand for 12 hours, remove the supernatant, and dry the lower sediment at 105°C for 24 hours; The final solid was transferred to a crucible and placed in a temperature-programmed muffle furnace, set to raise the temperature to 550° C. for 1 h, and roasted at this temperature for 1 h, and cooled naturally to room temperature. 0.9056gCo(NO 3 ) 3 ·6H 2 O and 0.3154gCe(NO 3 ) 3 ·6H 2 O was dissolved in 50ml deionized water; weigh 5g of the prepared 5% SiC-Al 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com