Energy-saving and consumption-reducing method and system for producing high-performance lithium battery negative electrode material

A negative electrode material, lithium battery technology, applied in chemical instruments and methods, climate sustainability, furnaces, etc., can solve the problems of unsatisfactory product resistivity index, long production cycle, high cost, and achieve the crystal plane spacing of graphite negative electrode material. Uniform densification, increased power drop rate, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

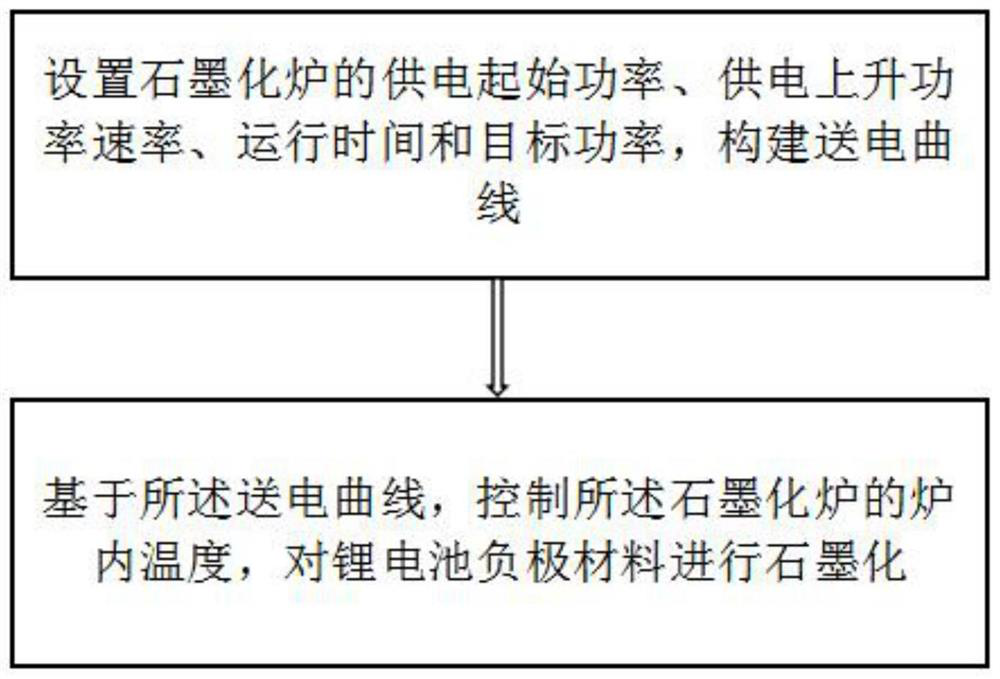

[0045] like figure 1 As shown, this embodiment provides a method for producing high-performance lithium battery negative electrode materials for energy saving and consumption reduction, including:

[0046] Set the initial power supply, rising power rate, running time and target power of the graphitization furnace to construct the power transmission curve;

[0047] Based on the power transmission curve, the temperature in the graphitization furnace is controlled to graphitize the negative electrode material of the lithium battery.

[0048]Further, the power supply rising power rate includes: a first rising power rate, a second rising power rate, a third rising power rate, a fourth rising power rate, a fifth rising power rate, a sixth falling power rate, and a seventh rising power rate. ;

[0049] The running time includes: the first running time, the second running time, the third running time, the fourth running time, the fifth running time, the sixth running time and the se...

Embodiment 2

[0082] The equipment used in this example is an Acheson graphitization furnace. First, the insulating material is filled into the furnace wall masonry of the graphitization furnace, a layer of resistance material is laid on the bottom of the furnace, and then the high-performance lithium battery negative electrode material that needs to be graphitized is placed Put it into the crucible, lay a layer of resistance material, and continue to put the crucible with the negative electrode material on it. The longitudinal direction of the crucible furnace is consistent with the longitudinal direction of the graphitization furnace, and then the upper layer of the crucible furnace is filled with insulating material.

[0083] Power transmission: The power transmission curve is: the initial power is 2800kW;

[0084] The calculated power starts from 2800kw, the rising power is 300kW / h, and after running for 3h, the reaching power is 3700kw;

[0085] The calculation power starts from 3700kw...

Embodiment 3

[0093] The equipment used in this example is an Acheson graphitization furnace. First, the insulating material is filled into the furnace wall masonry of the graphitization furnace, a layer of resistance material is laid on the bottom of the furnace, and then the high-performance lithium battery negative electrode material that needs to be graphitized is placed Put it into the crucible, lay a layer of resistance material, and continue to put the crucible with the negative electrode material on it. The longitudinal direction of the crucible furnace is consistent with the longitudinal direction of the graphitization furnace, and then the upper layer of the crucible furnace is filled with insulating material.

[0094] Power transmission: The power transmission curve is: the initial power is 3000kW;

[0095] The calculated power starts from 3000kw, the rising power is 400kW / h, and after running for 2h, the reaching power is 3800kw;

[0096] The calculated power starts from 3800kw, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com