A super-sized graphite product and its graphitization method

A technology of graphite products and super-large specifications, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of low furnace resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

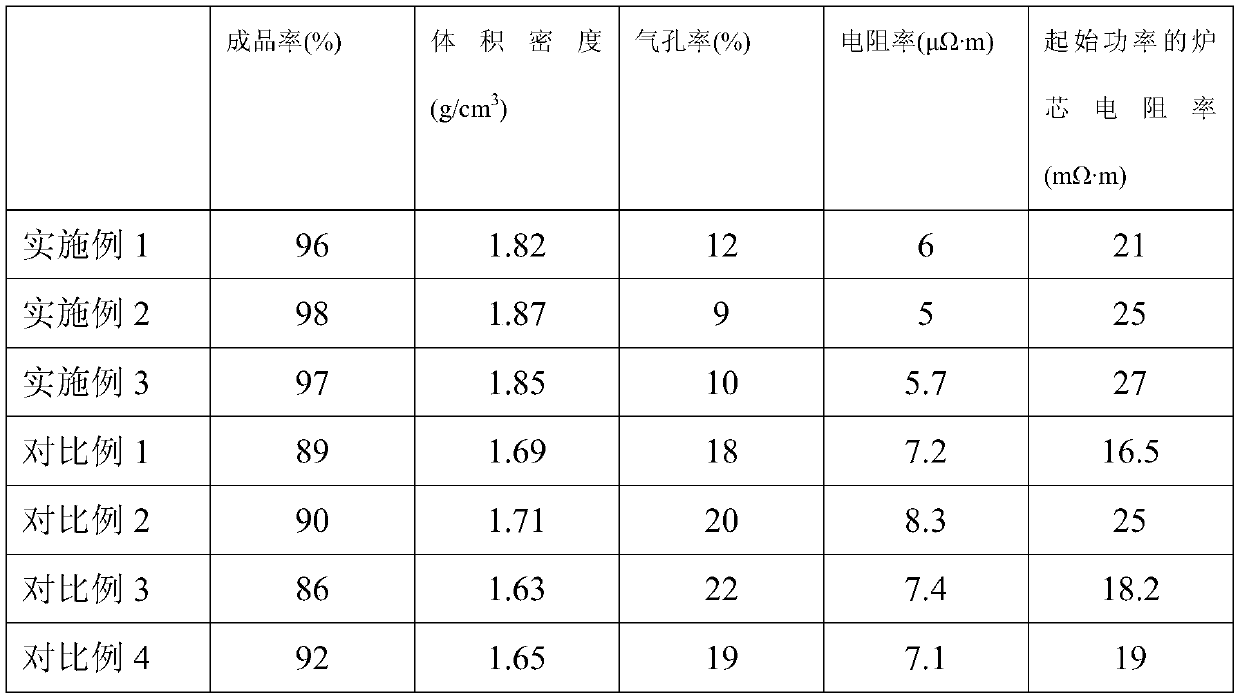

Examples

Embodiment 1

[0055] A graphitization method for ultra-large graphite products. The graphitization method includes preparing the furnace body, laying the furnace bottom, surrounding the furnace core, padding the bottom cushion, loading products, filling resistance materials, covering the top cushion, reaction materials and insulation materials, Power transmission, cooling. Specific steps are as follows:

[0056] (1) Prepare the furnace body: remove the furnace core resistance material, then clean the furnace side insulation material, so that the two materials do not mix, and finally clean the furnace bottom. After the silicon carbide layer is removed to the yellow material part, inspect the bottom of the furnace in three sections: front, middle and back, and check the structure of the yellow material. It can be used, but if the structure layer of the yellow material layer is thick and the hardness is strong, it needs to be cleaned. If there is a graphitized structure in the lower part of ...

Embodiment 2

[0079] (1) Prepare the furnace body: remove the furnace core resistance material, then clean the furnace side insulation material, so that the two materials do not mix, and finally clean the furnace bottom. After the silicon carbide layer is removed to the yellow material part, inspect the bottom of the furnace in three sections: front, middle and back, and check the structure of the yellow material. It can be used, but if the structure layer of the yellow material layer is thick and the hardness is strong, it needs to be cleaned. If there is a graphitized structure in the lower part of three sections or two of them, the bottom of the furnace must be completely removed. If only one section has a graphitized structure, expand the scope of local removal. The side wall insulation material needs to be cleaned up, and it is not allowed to replace the bottom material with the old insulation material. The sticky matter at the furnace head and tail needs to be cleaned every furnace....

Embodiment 3

[0102] (1) Prepare the furnace body: remove the furnace core resistance material, then clean the furnace side insulation material, so that the two materials do not mix, and finally clean the furnace bottom. After the silicon carbide layer is removed to the yellow material part, inspect the bottom of the furnace in three sections: front, middle and back, and check the structure of the yellow material. It can be used, but if the structure layer of the yellow material layer is thick and the hardness is strong, it needs to be cleaned. If there is a graphitized structure in the lower part of three sections or two of them, the bottom of the furnace must be completely removed. If only one section has a graphitized structure, expand the scope of local removal. The side wall insulation material needs to be cleaned up, and it is not allowed to replace the bottom material with the old insulation material. The sticky matter at the furnace head and tail needs to be cleaned every furnace....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com