Hydrolysis-resisting aluminum nitride powder and preparation method thereof

A technology of aluminum nitride and anti-hydrolysis, which is applied in the field of hydrolysis-resistant ceramic powder materials and powder surface treatment, aluminum nitride powder and its preparation, ceramic heat-conducting materials and its preparation, and achieves wide application range and simple process operation , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

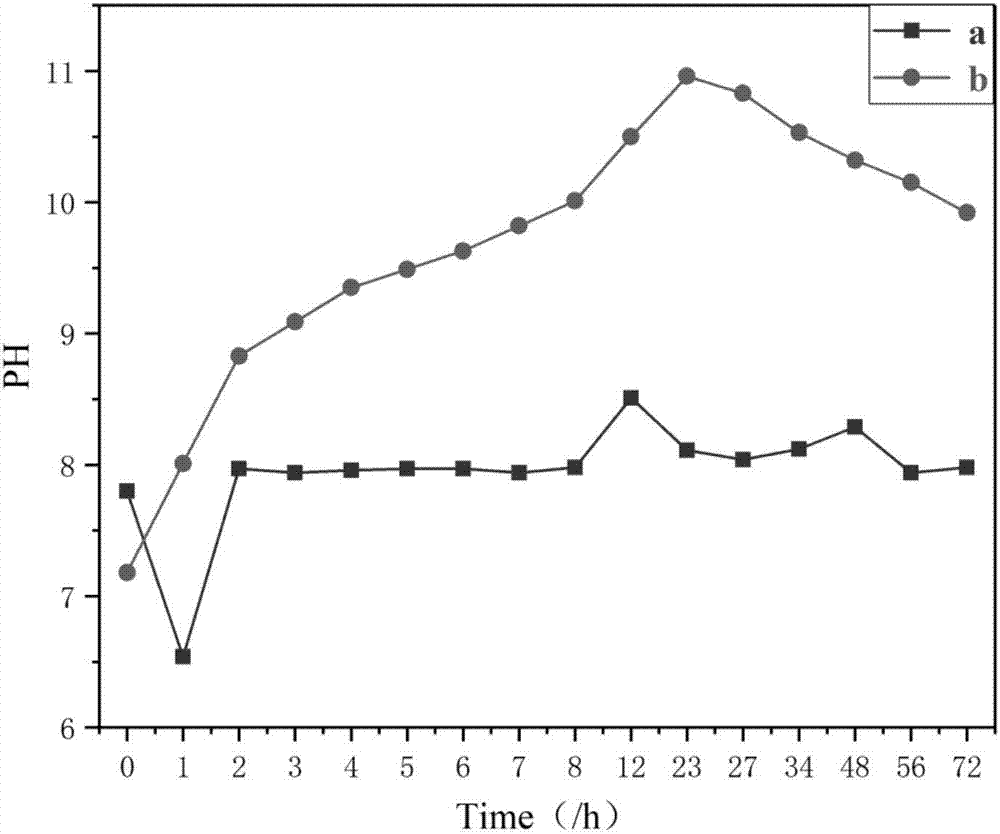

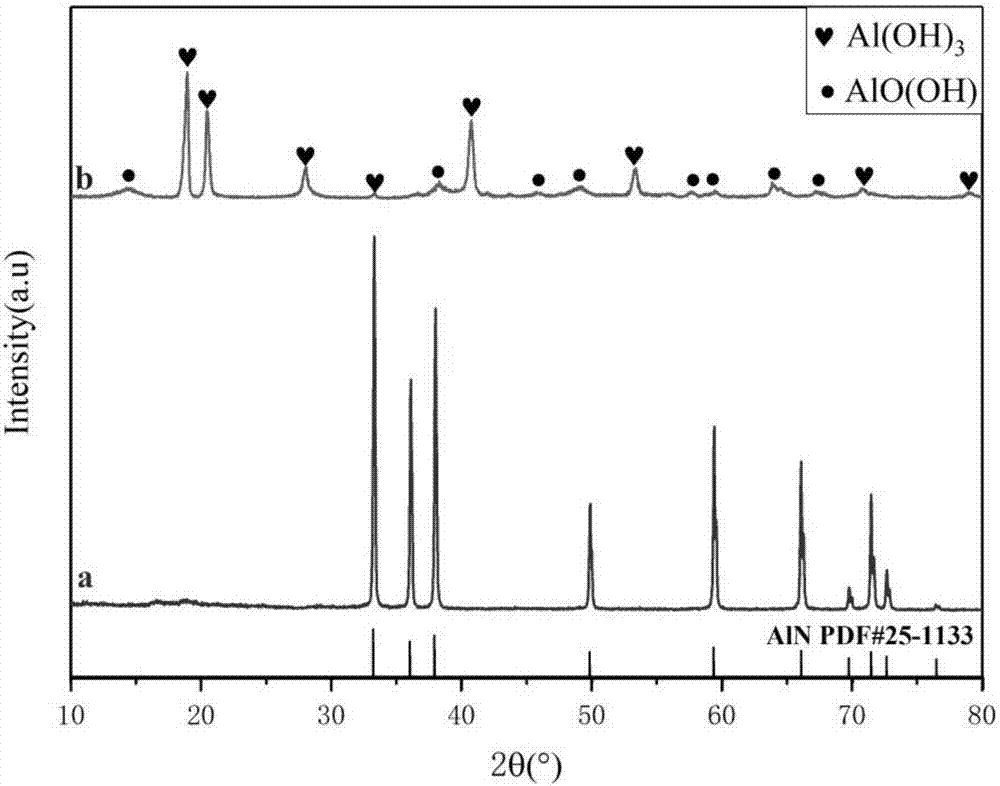

[0023] In this embodiment, a method for preparing an anti-hydrolysis aluminum nitride powder comprises the following steps:

[0024] (1) Weigh 0.6g of stearic acid, add it to 30ml of absolute ethanol solvent, and use magnetic stirring to disperse, place the organic acid mixture on a magnetic stirrer, stir for 20min, and the speed is 800r / min to fully disperse ;

[0025] (2) Adopting the ball milling dispersion method, the organic acid mixture prepared in step (1) and 20 g of AlN powder are added to the ball milling tank, the mixed slurry is evenly dispersed, and the ball milling speed is 200r / min; the ball milling dispersion time 1h, fully dispersed;

[0026] (3) Continue to use the ball milling dispersion method, add 2g of silane coupling agent KH560 dropwise at a uniform speed to the mixed slurry prepared in step (2), the ball milling speed is 250r / min; the ball milling dispersion time is 3h, fully disperse, and prepare Obtain aluminum nitride mixed slurry;

[0027] (4) F...

Embodiment 2

[0031] This embodiment is basically the same as Embodiment 1, especially in that:

[0032] In this embodiment, a method for preparing an anti-hydrolysis aluminum nitride powder comprises the following steps:

[0033](1) Weigh 0.4g of citric acid, add it to 80ml of absolute ethanol solvent, and use magnetic stirring to disperse, place the organic acid mixture on a magnetic stirrer, stir for 10min, and the speed is 600r / min to fully disperse;

[0034] (2) Add 20 g of AlN powder to the organic acid mixture prepared in step (1), adopt the paddle stirring dispersion method, put the mixed solution in a water bath stirrer, stir at 60 ° C for 2 h, and carry out fully dispersed;

[0035] (3) Add 2 g of silane coupling agent KH560 dropwise at a constant speed to the mixed liquid prepared in step (2), stir at 80° C. for 3 h, and fully disperse to prepare aluminum nitride mixed slurry;

[0036] (4) Filter and wash the aluminum nitride mixed slurry obtained in step (3), and dry at 80° C....

Embodiment 3

[0039] This embodiment is basically the same as the previous embodiment, and the special features are:

[0040] In this embodiment, a method for preparing an anti-hydrolysis aluminum nitride powder comprises the following steps:

[0041] (1) Weigh 1.2g of stearic acid, add it to 80ml of absolute ethanol solvent, and use magnetic stirring to disperse, place the organic acid mixture on a magnetic stirrer, stir for 20min, and the speed is 800r / min to fully disperse ;

[0042] (2) Add 30 g of AlN powder to the organic acid mixture prepared in step (1), adopt a paddle stirring dispersion method, put the mixture into an oil bath stirrer, and stir at 80° C. for 2 h, to fully disperse;

[0043] (3) Add 2 g of silane coupling agent KH550 dropwise at a constant speed to the mixed solution prepared in step (2), stir at 80°C for 4 hours, and fully disperse to prepare aluminum nitride mixed slurry;

[0044] (4) Filter and wash the aluminum nitride mixed slurry obtained in step (3), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com