Closed-cycle drying process for 3,3'-dimethyl-4,4'-diaminodiphenylmethane

A diaminodiphenylmethane, closed-circuit cycle technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problem that the emission content of o-methylaniline cannot meet the standard, the cost of incineration tail gas treatment is high, and the environment is unfavorable and other problems, to achieve the effect of improving the drying effect, simple structure and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

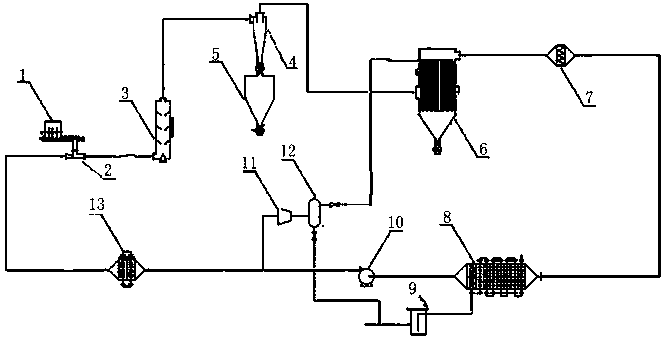

[0024] Such as figure 1 As shown, a MDT closed cycle drying process of the present invention can avoid the discharge of MDT dust particles during the drying process, and can recover the residual o-methylaniline in the waste gas to realize automatic control and clean production. It adopts a closed-circuit circulation drying system for drying. The closed-circuit circulation drying system includes a feeder 1, a feeder 2, a cyclone dryer 3, a cyclone separator 4, an automatic packaging machine 5, a bag filter 6, and a medium-efficiency filter 7. , condenser 8, waste liquid tank 9, circulating fan 10, air compressor 11, oil-water separator 12 and heat exchanger 13, feeder 1 and heat exchanger 13 are all connected to the inlet end of feeder 2, feeder 2 The outlet end of the outlet is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com