Multi-cavity type L-shaped anti-seismic corrosion resistant shear wall

A cavity-type, shear wall technology, applied in the direction of walls, fire protection, earthquake resistance, etc., can solve the problems of poor energy consumption, large reinforcement, increased construction strength and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

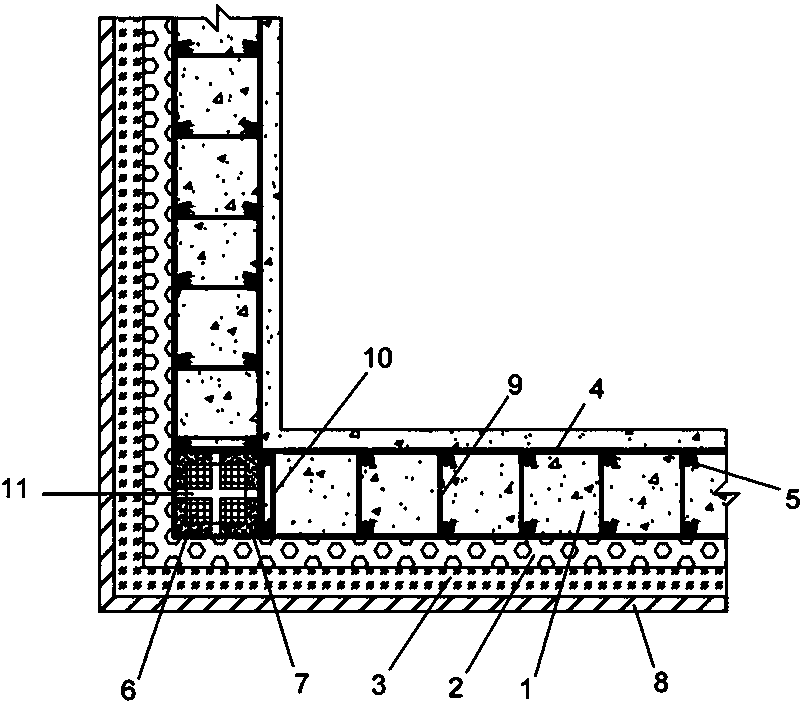

[0016] Example: as figure 1 As shown, it includes aerated concrete 1, foamed aluminum energy-consuming material 2, fire-proof insulation layer 3, cold-rolled energy-consuming steel plate 4, built-in reinforcement 5, supporting keel column 6, neoprene rubber layer 7, anti-corrosion protection layer 8, tensile strength Rib 9, reinforcement anchor ring 10 and cross support rib 11, cold-rolled energy-consuming steel plate 4 is preferably made of cold-rolled steel plate stamping; foamed aluminum energy-consuming material 2 is located on the outer layer of aerated concrete 1, and foamed aluminum 2 is the surface area porous aluminum foam; it is a low density, high specific surface area porous metal foam metal material with aluminum or aluminum alloy as the metal skeleton, which contains a large number of holes. Absorption, can be used as a cushioning material, aluminum foam is an excellent energy-absorbing, shock-absorbing and shock-resistant cushioning material, structurally, it ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com