Smelting method

A smelting method and smelting furnace technology, applied in the field of metallurgy, can solve the problems of waste slag flow, blocking the discharge port, and time-consuming, and achieve the effects of avoiding metal waste, shortening time, and avoiding clogging of collection tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

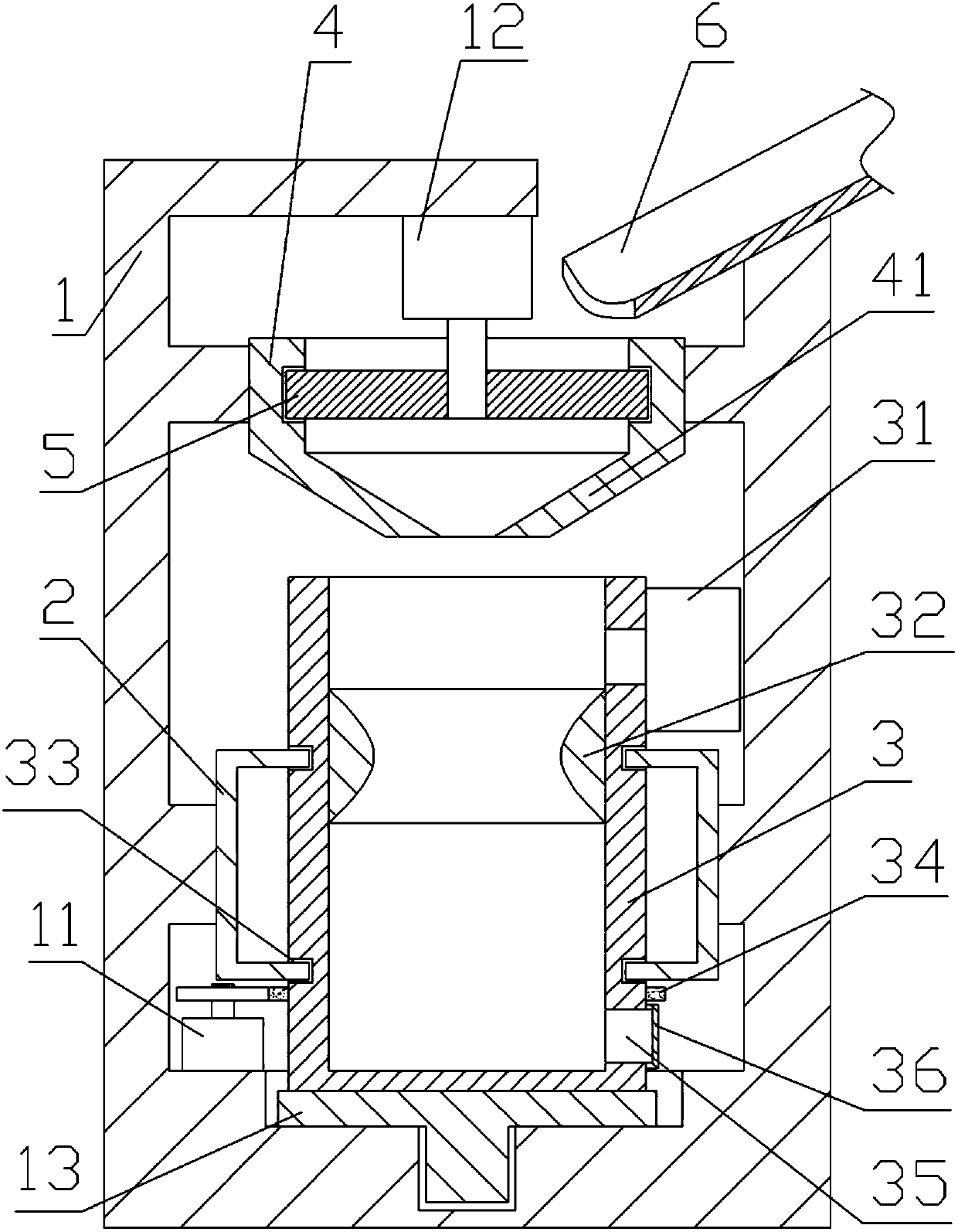

[0027] The reference signs are: frame 1, stepping motor 11, cutting motor 12, turntable 13, combustion cylinder 2, smelting furnace 3, collecting tank 31, slag retaining ring 32, chute 33, outer gear ring 34, slag outlet 35, cover body 36, outer tube 4, cutter 5, chute 6.

[0028] like figure 1 As shown, a smelting method adopts a fast-melting metallurgical furnace for smelting. The smelting furnace includes a frame 1 and a cutting mechanism and a smelting mechanism arranged sequentially from top to bottom. The cutting mechanism includes a cutter 5, a cutting motor 12 and an outer cylinder. 4. Outer cylinder 4 is positioned at cutter 5 periphery, and cutting motor 12 is fixed on the frame 1 and is positioned at the top of outer cylinder 4, and the output shaft of cutting motor 12 is welded with cutter 5 middle parts. The inner wall of the outer cylinder 4 is integrally formed with an annular rotating groove, and both ends of the cutter 5 are inserted into the rotating groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com