Negative electrode material with high temperature resistance, preparation method of negative electrode material and application of negative electrode material in lithium-ion battery

A technology of negative electrode material and polymer material, applied in the field of energy material preparation, can solve the problems of low retention rate and recovery rate, rapid capacity decay of soft carbon and hard carbon, etc., to avoid the formation of new film, low manufacturing cost, improve The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

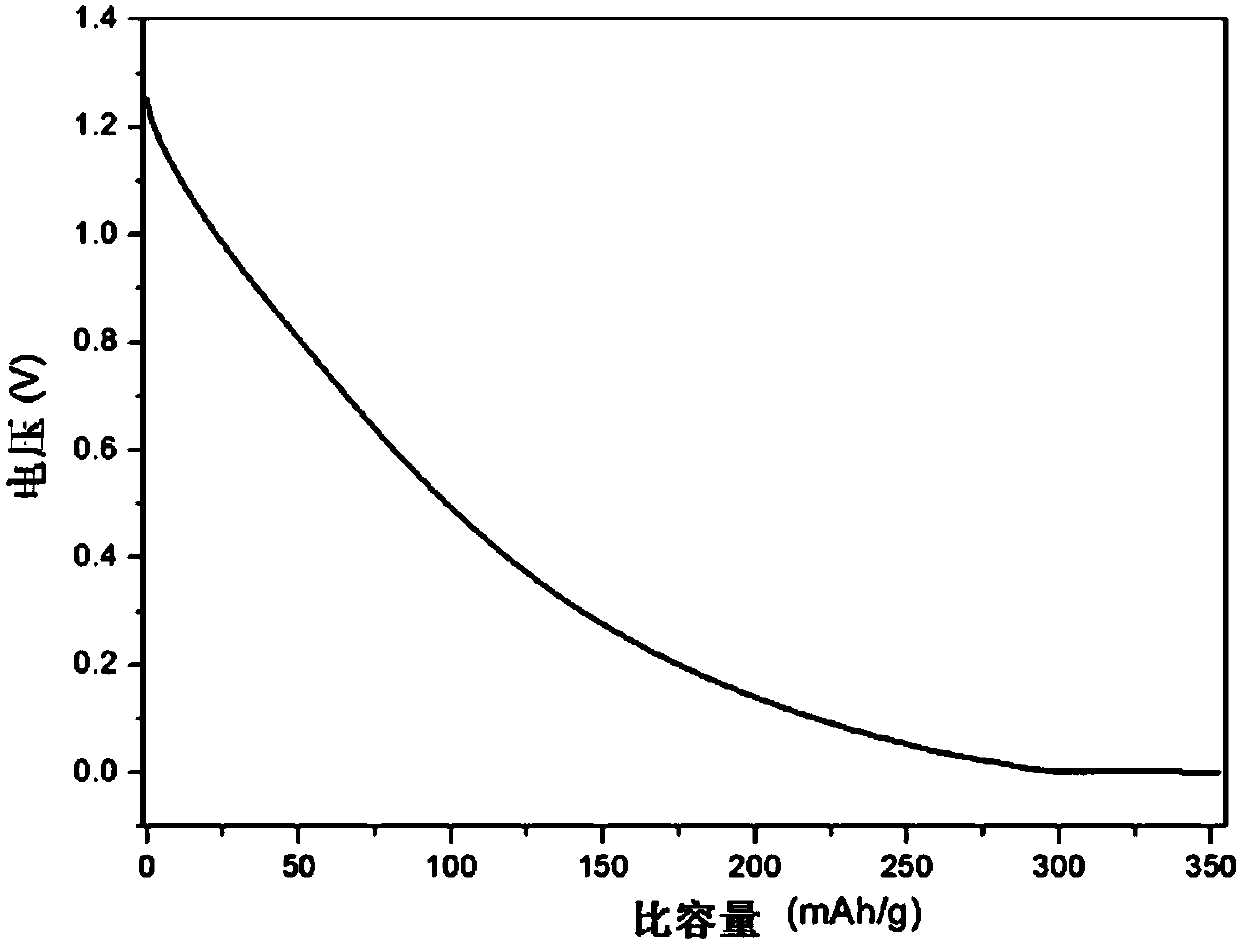

[0096] Dissolve 20g of tris buffer solution in 30g of water, adjust its pH value to 8.5 with ammonia water, then add 15g of dopamine at a stirring rate of 100rpm and stir for 20min, then add 150g of it with a conductivity of 50S / cm and a D50 particle size of 12μm The soft carbon powder was filtered after stirring for 1.5 hours, and then dried in a constant temperature oven at 80° C. to obtain a multifunctional polymer material coating material.

[0097] Take 22.5g Al(NO 3 ) 3 ·9H 2 O was dissolved in 300mL of water, and then 150g of multifunctional polymer coating material was added at an ultrasonic frequency of 100KHZ, followed by ultrasonication for 2h, and finally dried in an incubator at 80°C to obtain a nanomaterial coating material. Nano-coating coating material The coating material is processed in a tube furnace or a box furnace at a heating rate of 2 °C / min to 700 °C for 2 hours to obtain a negative electrode material for a lithium ion battery.

Embodiment 2

[0099] Dissolve 20g of tris buffer solution in 30g of water, adjust its pH value to 12.5 with ammonia water, then add 15g of dopamine at a stirring rate of 150rpm and stir for 20min, then add 150g of it with a conductivity of 50S / cm and a D50 particle size of 12μm The hard carbon powder was stirred for 1.5 hours, then filtered, and then dried in a constant temperature oven at 80° C. to obtain a multifunctional polymer material coating material.

[0100] Take 22.5g Al(NO 3 ) 3 ·9H 2 O was dissolved in 300mL of water, and then 150g of multifunctional polymer material coating material was added at an ultrasonic frequency of 100KHZ, followed by ultrasonication for 2h, and finally dried in a thermostat at 80°C to obtain a nano-coating coating material. The nano-coating coating material is treated in a tube furnace or a box furnace at a heating rate of 2 °C / min to 700 °C for 2 hours to obtain a negative electrode material for a lithium-ion battery.

Embodiment 3

[0102] Dissolve 20g of tris buffer solution in 30g of water, adjust its pH value to 8.5 with ammonia water, then add 15g of dopamine at a stirring rate of 100rpm and stir for 20min, then add 150g of it, the conductivity is 50S / cm, and the D50 particle size is 12μm The soft carbon powder is then stirred and ultrasonicated (the stirring rate is 100rpm and the ultrasonic frequency is 100KHZ) for 1.5h at the same time, and finally filtered and dried in an incubator at 80°C to obtain a multifunctional polymer material coating material.

[0103] Take 22.5g Al(NO 3 ) 3 ·9H 2 O was dissolved in 300mL of water, and then 150g of multi-functional polymer material coating material was added at an ultrasonic frequency of 100KHZ, followed by ultrasonication for 2h, and finally dried in an incubator at 80°C to obtain a nanomaterial coating material. The nano-coating coating material is treated in a tube furnace or a box furnace at a heating rate of 2 °C / min to 700 °C for 2 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com