Method for analyzing 6-ethylchenodeoxycholic acid and synthetic intermediate thereof by high-performance liquid chromatography

A high-performance liquid chromatography, obeticholic acid technology, applied in the field of high-performance liquid chromatography analysis of obeticholic acid and its synthetic intermediates, to achieve the effects of ensuring quality controllability, ensuring stability, and improving symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Instruments and Conditions:

[0027] High performance liquid chromatography: high performance liquid chromatography (Agilent 1260);

[0028] Chromatographic column: Thermo Syncronis C18 column (250mm×4.6mm, 5μm);

[0029] Mobile phase: 0.01mol / L potassium dihydrogen phosphate solution: acetonitrile:methanol=30:55:15(v:v:v);

[0030] Flow rate: 1.0ml / min;

[0031] Column temperature: 35°C;

[0032] Detector temperature: 35°C;

[0033] Injection volume: 100 μl.

[0034] Implementation steps:

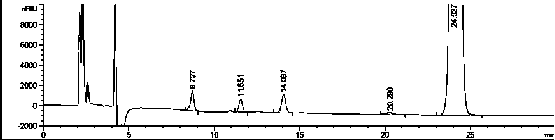

[0035] Weigh 300 mg of obeticholic acid and 1 mg of each intermediate, respectively, and place in a 100 ml measuring bottle, dissolve with mobile phase, dilute to constant volume, and use it as the test solution. Measure 100 μl of the above solution and inject it into the liquid chromatograph, record the chromatogram, the result is as follows: figure 1 . Calculated by the area normalization method, the number of theoretical plates calculated by obeticholic acid is ≥2000, the...

Embodiment 2

[0038] Instruments and Conditions:

[0039] High performance liquid chromatography: high performance liquid chromatography (Agilent 1260);

[0040] Chromatographic column: Thermo Syncronis C18 column (250mm×4.6mm, 5μm);

[0041] Mobile phase: 0.005mol / L potassium dihydrogen phosphate solution: acetonitrile:methanol=30:55:15(v:v:v);

[0042] Flow rate: 1.0ml / min;

[0043] Column temperature: 35°C;

[0044] Detector temperature: 35°C;

[0045] Injection volume: 100 μl.

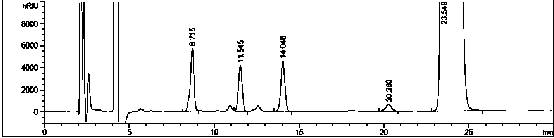

[0046] Implementation steps: Weigh 300 mg of obeticholic acid and 1 mg of each intermediate, put them in a 100 ml measuring bottle, dissolve with mobile phase, dilute to constant volume, and use it as the test solution. Measure 100 μl of the above solution and inject it into the liquid chromatograph, record the chromatogram, the result is as follows: figure 2 . Weigh 300mg of obeticholic acid synthesized independently and place it in a 100ml measuring bottle, dissolve it with mobile phase, dilute to cons...

Embodiment 3

[0050] Instruments and Conditions:

[0051] High performance liquid chromatography: high performance liquid chromatography (Agilent 1260);

[0052] Chromatographic column: Thermo Syncronis C18 column (250mm×4.6mm, 5μm);

[0053] Mobile phase: 0.005mol / L sodium dihydrogen phosphate solution: acetonitrile:methanol=25:57:18(v:v:v);

[0054] Flow rate: 1.0ml / min;

[0055] Column temperature: 40°C;

[0056] Detector temperature: 40°C;

[0057] Injection volume: 80 μl.

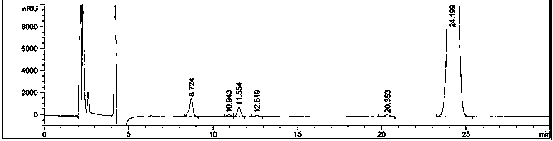

[0058] Implementation steps: Weigh 300 mg of obeticholic acid and 1 mg of each intermediate, put them in a 100 ml measuring bottle, dissolve with mobile phase, dilute to constant volume, and use it as the test solution. Measure 80 μl of the above solution and inject it into the liquid chromatograph, record the chromatogram, the result is as follows: Figure 4 . Weigh 300mg of obeticholic acid synthesized independently and place it in a 100ml measuring bottle, dissolve it with mobile phase, dilute to constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com