Solvent-free wear-resistant pattern coating

A pattern paint, solvent-free technology, applied in the field of paint, can solve the problems of human body damage, atmospheric environment pollution, etc., and achieve the effects of easy maintenance, good corrosion resistance, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

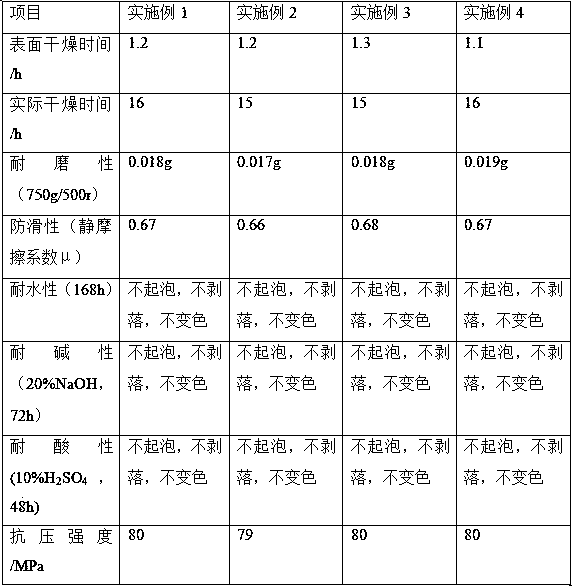

Examples

Embodiment 1

[0022] The solvent-free wear-resistant pattern paint is composed of component A and component B, wherein component A includes the following raw materials: by weight, 30 parts of bisphenol A epoxy resin, 20 parts of bisphenol F epoxy resin , 10 parts of ethylene glycol diglycidyl ether, 5 parts of glycerin epoxy resin, 40 parts of talc powder, 20 parts of silica powder, 1.0 part of BYK-310, 0.5 part of BYK-354, 1 part of BYK-054, color paste 8 copies;

[0023] Component B includes the following raw materials: 20 parts of modified alicyclic amine, 10 parts of ethylenediamine, and 0.8 part of n-butyric acid. The mass ratio of the A component to the B component is 5:1.

[0024] The construction method of the solvent-free wear-resistant pattern paint:

[0025] (1) Mix component A and component B in proportion and stir evenly to obtain the coating;

[0026] (2) On the leveled floor, pour the paint obtained in step (1) into a single-color or two-color spraying and printing dual-pu...

Embodiment 2

[0030] The solvent-free wear-resistant pattern paint is composed of component A and component B, wherein component A includes the following raw materials: by weight, 35 parts of bisphenol A epoxy resin, 22 parts of bisphenol F epoxy resin , 13 parts of ethylene glycol diglycidyl ether, 8 parts of glycerin epoxy resin, 50 parts of talc powder, 25 parts of silicon dioxide powder, 1.2 parts of BYK-310, 0.8 parts of BYK-354, 1.2 parts of BYK-054, color paste 9 copies;

[0031] Component B includes the following raw materials: 25 parts of modified alicyclic amine, 12 parts of ethylenediamine, and 1.0 part of n-butyric acid.

[0032] The mass ratio of the A component to the B component is 5:1.

[0033] The construction method of the solvent-free wear-resistant pattern paint:

[0034] (1) Mix component A and component B in proportion and stir evenly to obtain the coating;

[0035] (2) On the leveled floor, pour the paint obtained in step (1) into a single-color or two-color sprayi...

Embodiment 3

[0039] The solvent-free wear-resistant pattern paint is composed of component A and component B, wherein component A includes the following raw materials: by weight, 40 parts of bisphenol A epoxy resin, 25 parts of bisphenol F epoxy resin , 15 parts of ethylene glycol diglycidyl ether, 10 parts of glycerin epoxy resin, 60 parts of talc powder, 30 parts of silicon dioxide powder, 1.5 parts of BYK-310, 0.9 parts of BYK-354, 1.5 parts of BYK-054, color paste 10 copies;

[0040] Component B includes the following raw materials: 30 parts of modified alicyclic amine, 15 parts of ethylenediamine, and 1.5 parts of n-butyric acid.

[0041] The mass ratio of the A component to the B component is 5:1.

[0042] Construction method reference embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com