A kind of ceramic composite lithium-ion battery diaphragm and preparation method thereof

A lithium-ion battery and ceramic composite technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of poor thermal stability of the diaphragm, poor bonding performance between ceramic powder and base material, etc., and achieve high peeling Strength, high strength, uniform and stable dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

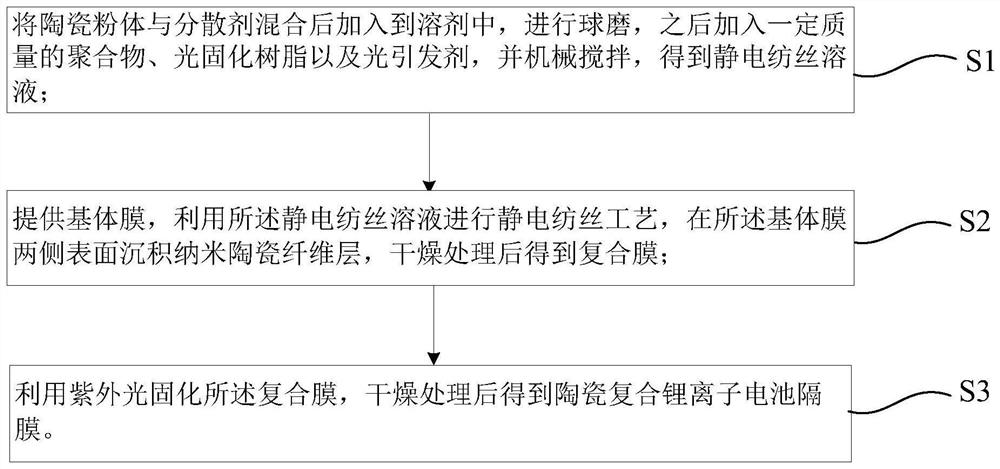

[0030] Please refer to the attached figure 1 , the present invention provides a kind of preparation method of ceramic composite lithium-ion battery separator, and described preparation method comprises the following steps at least:

[0031] First perform step S1, mix the ceramic powder and the dispersant, add it to the solvent, and perform ball milling, then add a certain mass of polymer, photocurable resin, and photoinitiator, and stir mechanically to obtain an electrospinning solution.

[0032] As an example, in the obtained electrospinning solution, the weight percentage is as follows: the polymer is 10wt%-30wt% of the electrospinning solution, and the solvent is 70wt% of the electrospinning solution -90wt%, the ceramic powder is 5wt%-50wt% of the polymer, the dispersant is 0.1wt%-0.5wt% of the ceramic powder, the photocurable resin is the polymer 2wt%-5wt% of said photoinitiator is 5wt%-20wt% of said photocurable resin.

[0033]Preferably, the polymer is 20wt%-30wt% of t...

Embodiment 1

[0054] This embodiment provides a preparation method of a ceramic composite lithium-ion battery separator, the preparation steps comprising:

[0055] 1) Preparation of electrospinning solution: the particle size is between 20nm-5μm Al 2 o 3 After mixing with the dispersant polypyrrolidone, it was added to the dissolved dimethylacetamide for ball milling for 3 hours. The electrospinning solution was prepared by adding polyarylsulfone, epoxy acrylate, and 2-hydroxy-2-methyl-1-phenylacetone into the above solution and mechanically stirring at 50° C. for 6 hours. The electrospinning solution is composed of: polyarylsulfone 10wt%, dimethylacetamide 90wt%; Al 2 o 3 It is 10wt% of polyarylsulfone, the dispersant polypyrrolidone is Al 2 o 3 0.1wt% of epoxy acrylate, 2wt% of polyarylsulfone; 2-hydroxy-2-methyl-1-phenylacetone is 5wt% of epoxy acrylate.

[0056] 2) Preparation of nano-ceramic fiber layer: The prepared solution is subjected to an electrospinning process, and a nano...

Embodiment 2

[0060] This embodiment provides a preparation method of a ceramic composite lithium-ion battery separator, the preparation steps comprising:

[0061] 1) Preparation of electrospinning solution: the particle size is between 20nm-5μmZrO 2 After mixing with the dispersant polyacrylate, it was added to the dissolved dimethylformamide for ball milling for 4 hours. The electrospinning solution was prepared by adding polyimide, polyurethane acrylate, and 1-hydroxycyclohexyl phenyl ketone into the above solution and mechanically stirring at 60° C. for 8 hours. The composition of electrospinning solution is: polyimide 12wt%, dimethylformamide 88wt%; ZrO 2 15wt% of polyimide, dispersant polypyrrolidone is ZrO 2 0.2wt% of urethane acrylate is 3wt% of polyarylsulfone; 2-hydroxy-2-methyl-1-phenylacetone is 10wt% of epoxy acrylate.

[0062] 2) Preparation of nano-ceramic fiber layer: The prepared solution is subjected to an electrospinning process, and a nano-ceramic fiber layer is depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com