Machining technology of duplex chain wheel

A processing technology and double-row sprocket technology, applied in metal processing equipment, metal material coating technology, coating, etc., can solve the problems of easy rust, damage to the shape accuracy of sprockets, and easy burrs, etc., to achieve production The process is simple, the appearance quality is improved, and the heating part is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

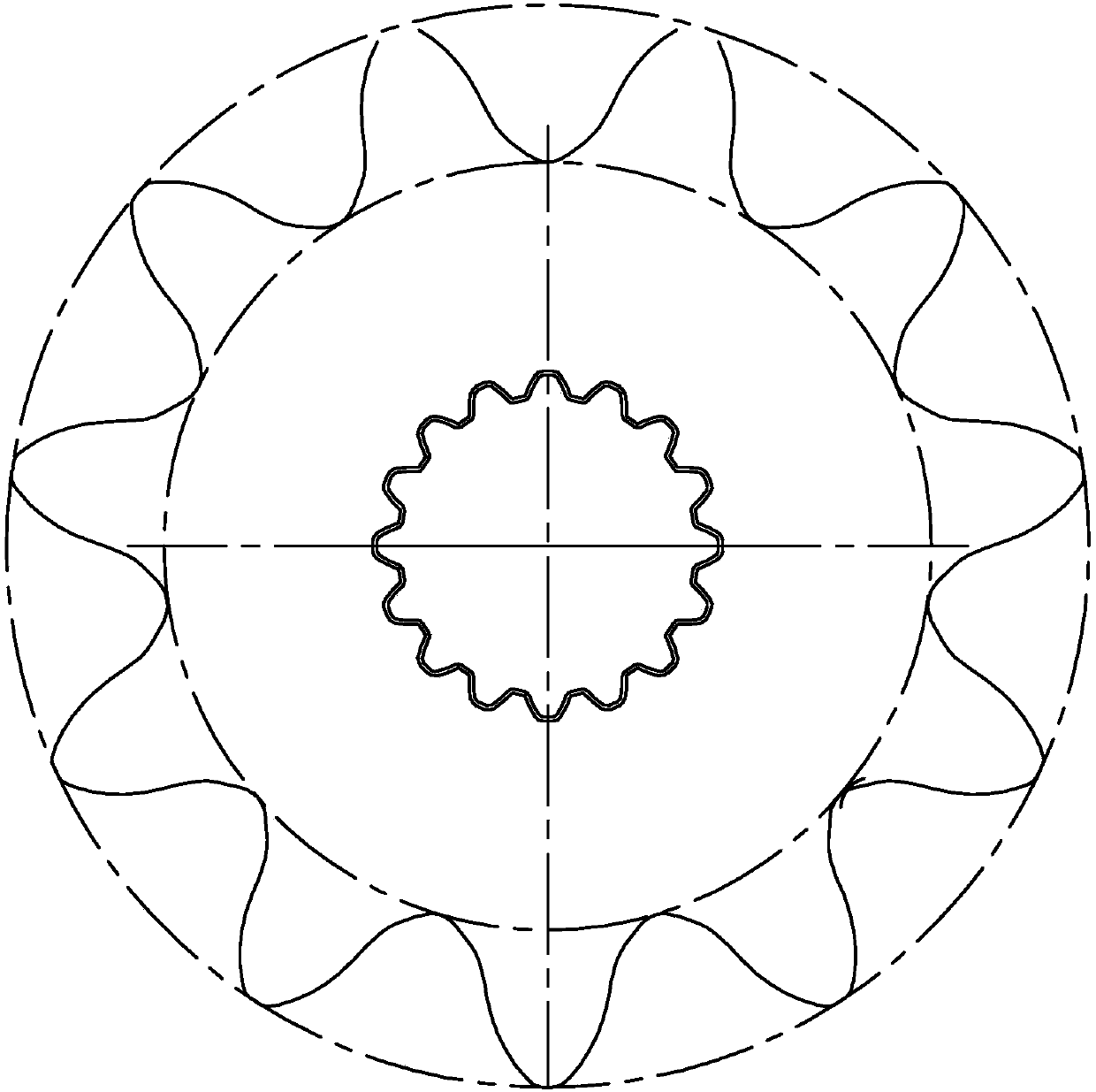

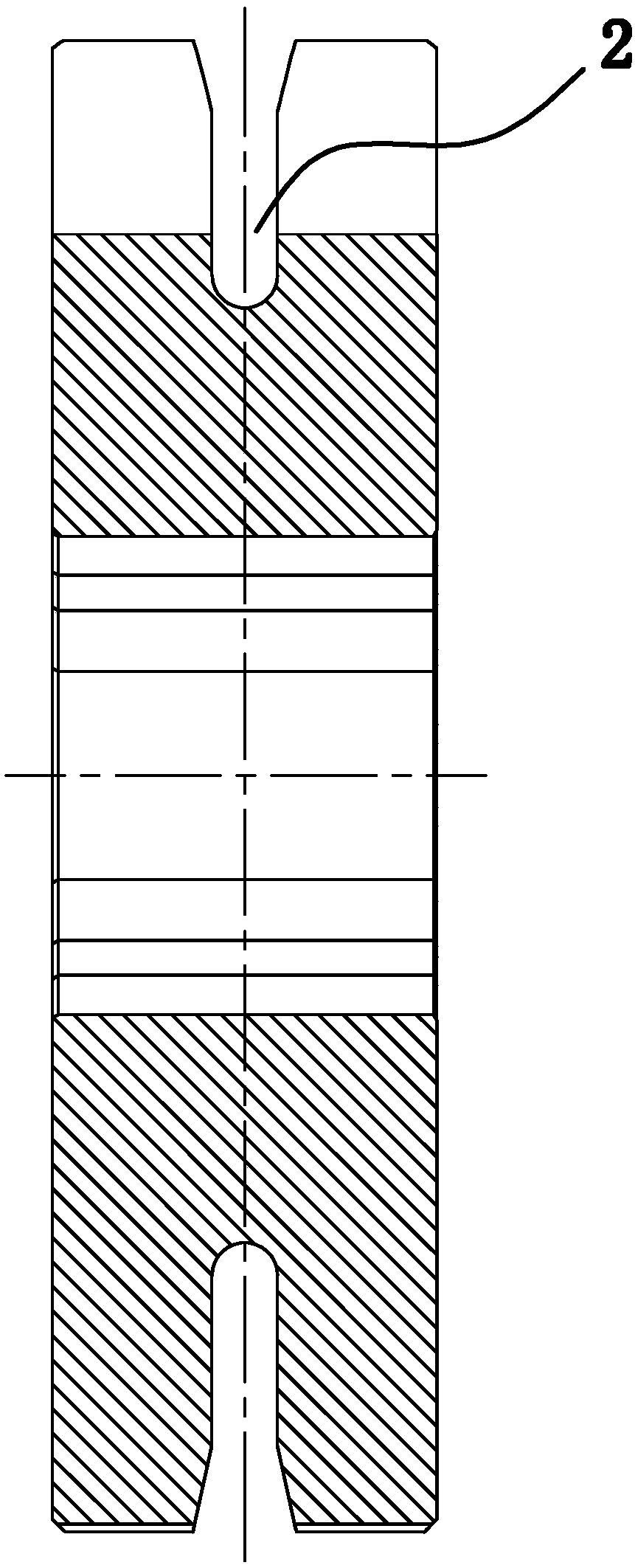

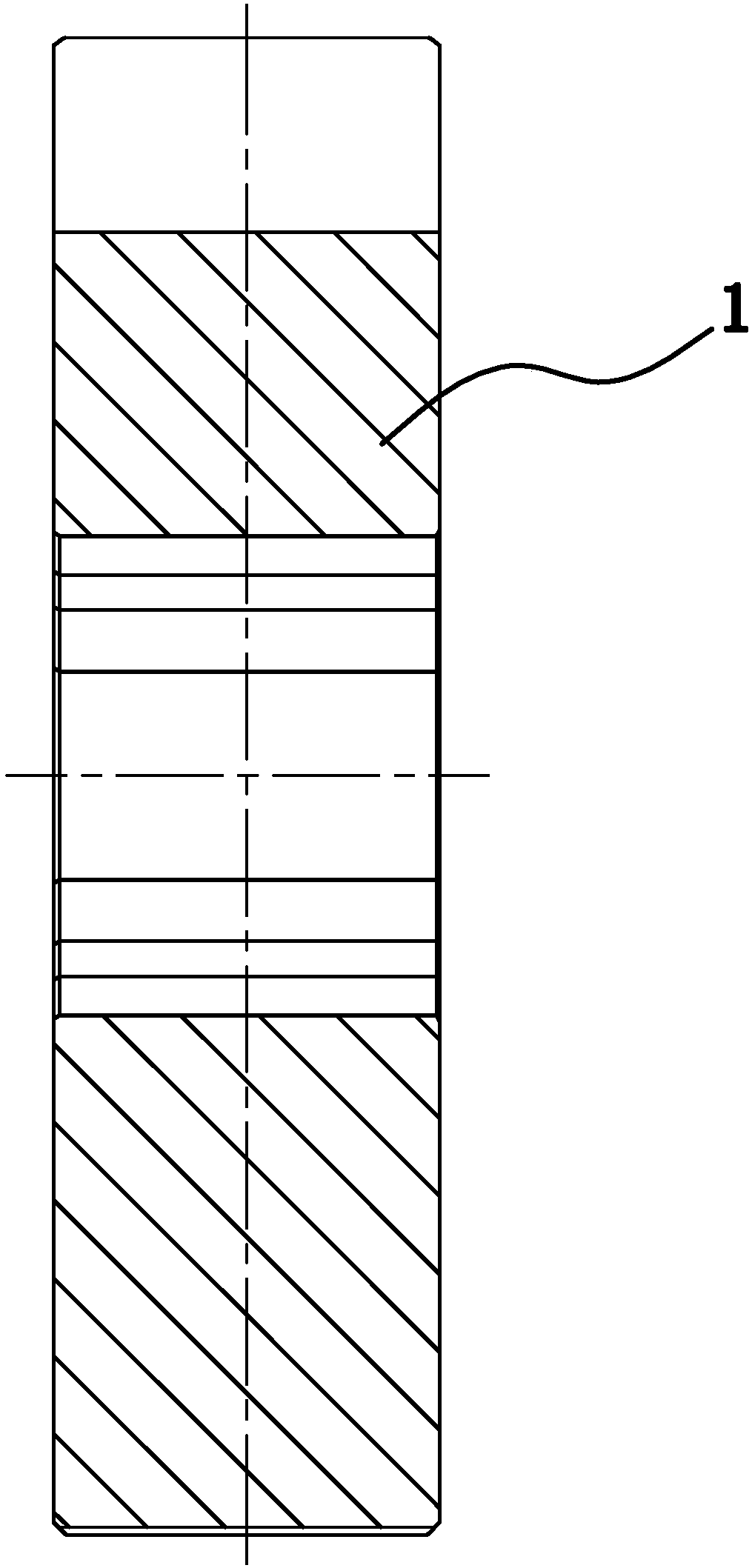

Image

Examples

Embodiment 1

[0036] The double-row sprocket is made of the following raw materials in mass percentage: iron powder 92-94, copper powder 2.5-2.8, manganese powder 0.4-1.0, nickel powder 1.8-2.6, graphite powder 0.4-1.0, chromium powder 0.2-0.6, lubricated Agent 0.6~1.0, anti-segregation binder 0.30~0.5.

[0037] The double row sprocket processing technology comprises the following steps:

[0038] A. Mixing: Put the raw materials including iron powder, copper powder, manganese powder, nickel powder, chromium powder, graphite powder, lubricant and anti-segregation binder into the mixer for stirring and mixing. Preferably, the proportions of the above raw materials are: iron powder 93, copper powder 2.6, manganese powder 0.5, nickel powder 2.0, graphite powder 0.5, chromium powder 0.4, lubricant 0.8, and segregation-preventing binder 0.4.

[0039] B. Pour the mixed raw materials into the mold and press to make the density 7.3~7.36g / cm 3 The compact 1, wherein the temperature of the control m...

Embodiment 2

[0050] The structure and principle of the second embodiment are basically the same as the first embodiment, the difference is that the ratio of the raw materials used to manufacture the double-row sprocket is: iron powder 92, copper powder 2.5, manganese powder 0.4, nickel powder 1.8, Graphite powder 0.4, chrome powder 0.2, lubricant 0.6, anti-segregation binder 0.3.

Embodiment 3

[0052]The structure and principle of this third embodiment are basically the same as that of the first embodiment, except that the ratio of the raw materials used to manufacture the double row sprocket is: iron powder 94, copper powder 2.8, manganese powder 1.0, nickel powder 2.6, Graphite powder 1, chrome powder 0.6, lubricant 1, anti-segregation binder 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com