A kind of multi-layer gel material and preparation method for lithium battery recycling

A multi-layer gel and lithium battery technology, applied in the field of metal ion adsorption materials, can solve the problems of cumbersome procedures, low degree of continuity, and great harm to the body, and achieve simple preparation process, low degree of continuity, and reduce secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

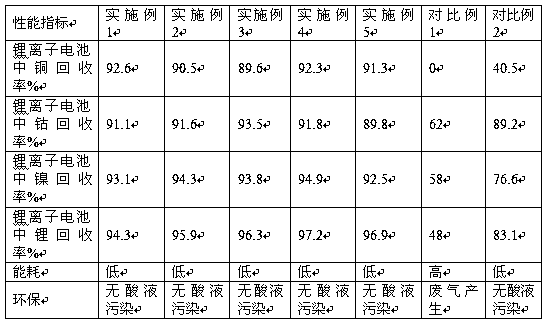

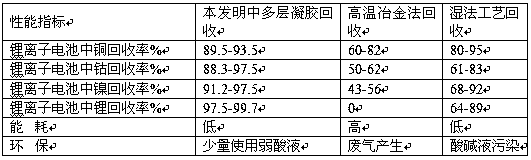

Examples

Embodiment 1

[0035](1) First weigh montmorillonite, chitosan and activated carbon according to the mass ratio of 1:1:1, divide the agar gel into three parts, the volume ratio of the three agar gels is 3:2:1, and the montmorillonite Stone is mixed with 3 volumes of agar gel, chitosan is mixed with 2 volumes of agar gel, activated carbon is mixed with 1 volume of agar gel, and after high-speed stirring, three kinds of agar gel adsorption materials that are uniformly dispersed are obtained. The particle diameter of montmorillonite is 300 orders, porosity 40%, the particle diameter of described chitosan is 600 orders, porosity 60%, the particle diameter of described activated carbon is 1200 orders, porosity 85%;

[0036] (2) Mix the above three agar gel adsorption materials with the adhesive silica gel, and stir evenly to obtain a viscous adsorption material;

[0037] (3) Coat the above three kinds of viscous gel adsorption materials on the surface of high-porosity reticular porous silicon res...

Embodiment 2

[0041] (1) First weigh montmorillonite, chitosan and activated carbon according to the mass ratio of 1:1:1, divide the agar into three parts with a volume ratio of 3:2:1, mix the montmorillonite with 3 volumes of agar, Chitosan is mixed with 2 volumes of agar, activated carbon is mixed with 1 volume of agar, and stirred at a high speed to obtain three uniformly dispersed gel adsorption materials. The particle size of the montmorillonite is 300 mesh, and the porosity is 45%. The particle diameter of described chitosan is 600 orders, and porosity is 65%, and the particle diameter of described gac is 1600 orders, and porosity is 87%;

[0042] (2) Mix the three kinds of gel adsorption materials with the adhesive starch, and stir evenly to obtain a viscous adsorption material;

[0043] (3) The three kinds of viscous gel adsorption materials are respectively coated on the surface of the high-porosity reticular porous silicon. The pore diameter of the high-porosity reticular porous s...

Embodiment 3

[0047] (1) First weigh montmorillonite, chitosan and activated carbon according to the mass ratio of 1:1:1, divide the gelatin into three parts with a volume ratio of 3:2:1, montmorillonite and 3 volumes of gelatin Mixing, chitosan is mixed with 2 volumes of gelatin, activated carbon is mixed with 1 volume of gelatin, and stirred at a high speed to obtain three uniformly dispersed gel adsorption materials, the particle size of the montmorillonite is 350 mesh, and the pores Rate 45%, the particle diameter of described chitosan is 700 orders, porosity 70%, the particle diameter of described activated carbon is 1500 orders, porosity 88%;

[0048] (2) Mix the three kinds of gel adsorption materials with the adhesive starch, and stir evenly to obtain a viscous adsorption material;

[0049] (3) The three kinds of viscous gel adsorption materials are respectively coated on the surface of high-porosity reticular porous silicon, the pore diameter of the high-porosity reticular porous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com