Desulphurization-denitration cooperative treatment method for flue gas of hot-blast stoves

A waste gas desulfurization and hot blast stove technology, which is applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as air pollution, increase combustion temperature and vault temperature, save energy consumption, and reduce water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

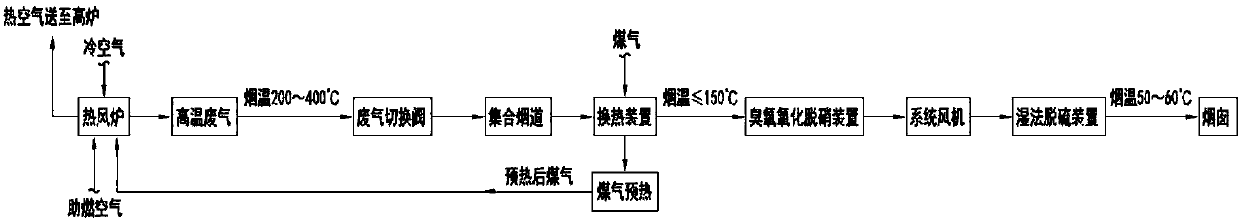

[0025] The embodiment of the present application provides a co-treatment method for desulfurization and denitrification of exhaust gas from hot blast stoves, which solves the technical problem that there is no relevant equipment or process in the prior art to purify the exhaust gas of hot blast stoves, resulting in air pollution, and realizes exhaust gas purification, hot blast Transmission and waste heat recovery are carried out simultaneously with gas preheating. The purification efficiency is high, which can meet the requirements of new standard emission limits or ultra-low emission requirements. The technical effects of waste heat utilization, energy saving and consumption reduction, and operating cost reduction.

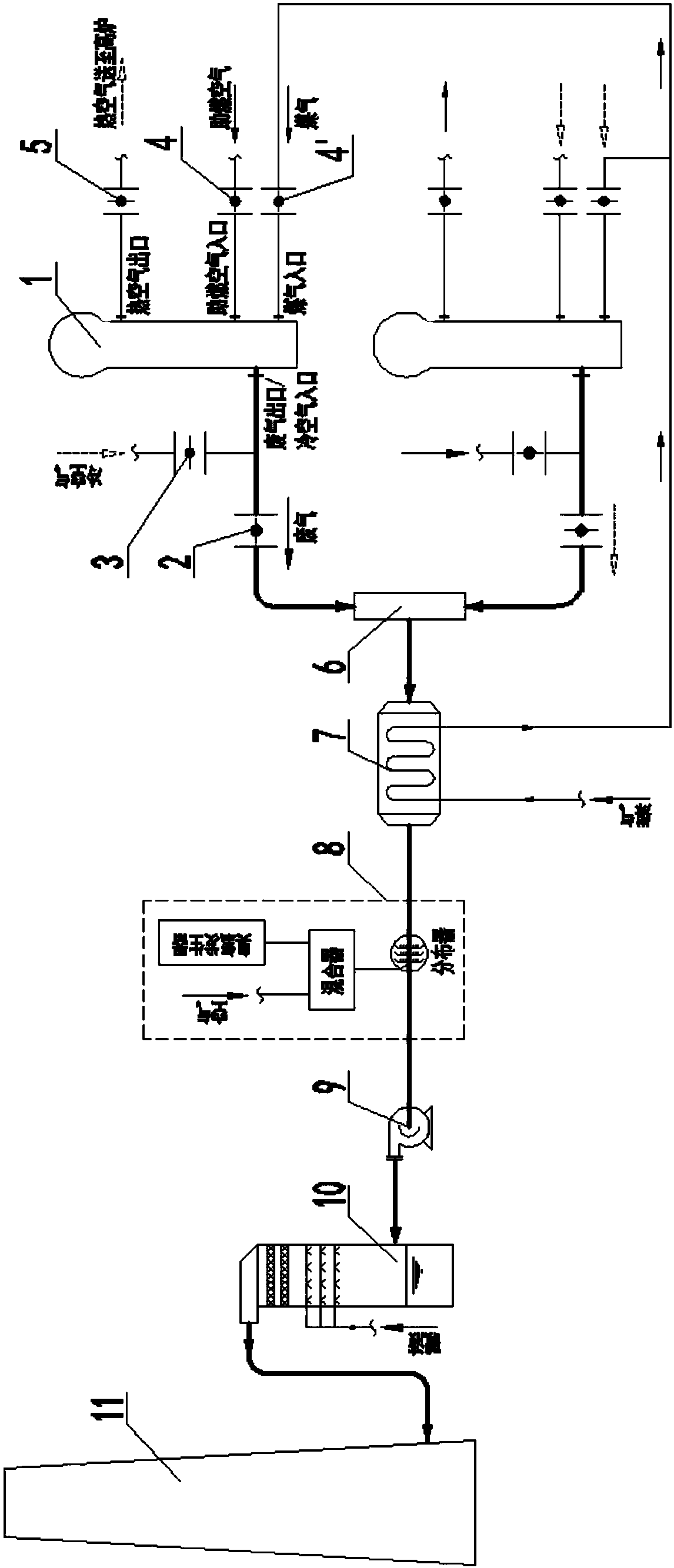

[0026] See attached figure 1 , The present invention provides a method for synergistic treatment of desulfurization and denitrification of exhaust gas from hot blast stoves. The implementation device mainly includes: several hot blast stoves 1, a collection flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com