A welded cable conductor joint with current equalizing function and its welding method

A technology for welding joints and cable conductors, which is applied in the direction of welding/welding connections, connections, circuits, etc., which can solve the problems of not considering the connection between the cable intermediate joint and the cable outlet conductor, reduce the skin effect of the conductor, etc., and increase the current. Uniformity of distribution, reduction of line running loss, and the effect of overcoming temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

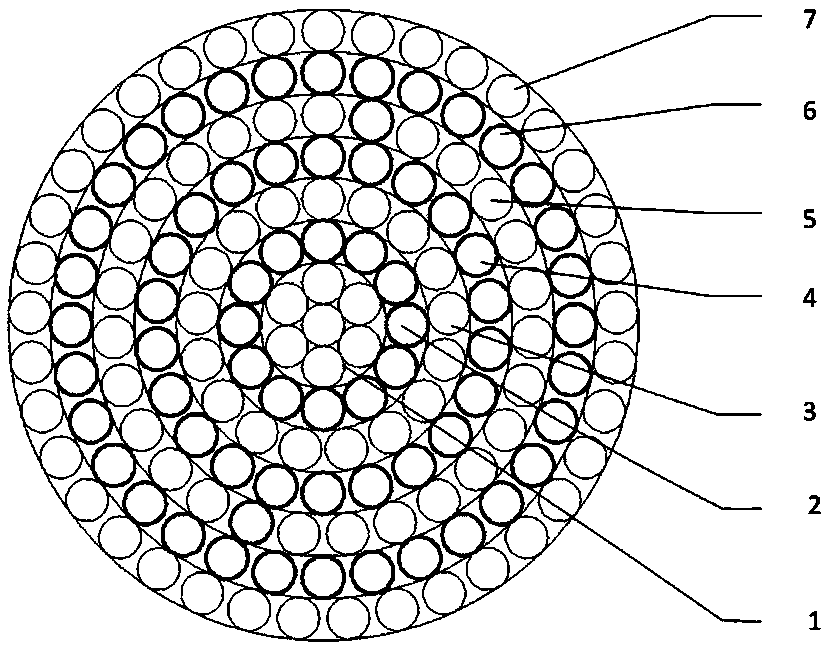

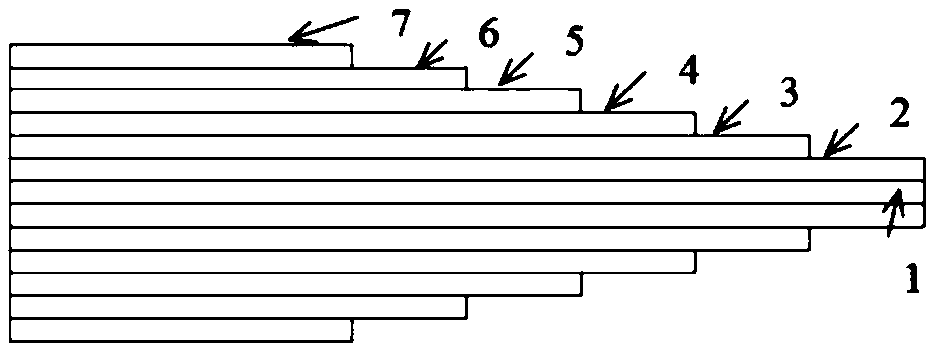

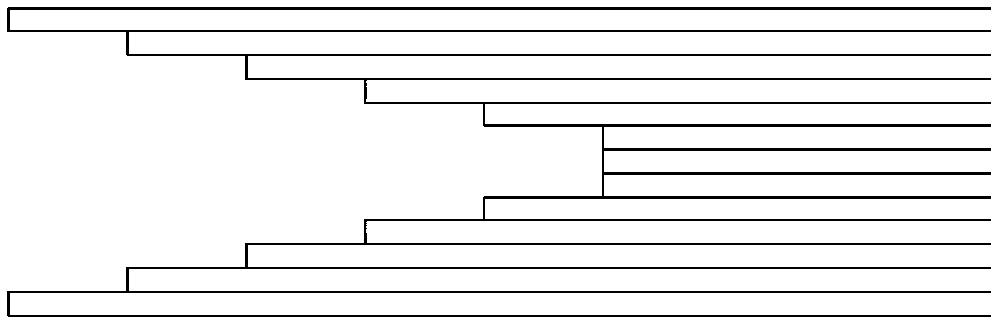

[0033] The total number of layers of the conductor is 7 layers, and the conductor is divided into two parts for welding. The inner welding layer is 5 layers and the outer welding layer is 2 layers. Before welding starts, use a pipe cutter to make the male head of the welded joint. The outer layer of the conductor monofilament is 15mm shorter than the adjacent inner layer, and the two layers in the center are sawed flush. eventually into a ladder figure 2 As shown, and fasten each layer tightly. Use low-resistivity electrode A when welding the inner 5-layer conductor, and use high-resistivity electrode B when welding the outer 2-layer conductor. The production of the female head of the welded joint is carried out in conjunction with the male head. First, use a pipe cutter to cut the conductor on each layer. The outer layer of the conductor monofilament is 15mm longer than the adjacent inner layer, and the two layers in the center are sawed evenly. image 3 , use low-resistiv...

Embodiment 2

[0036] The total number of layers of the conductor is 7 layers, and the conductor is divided into two parts for welding. The inner welding layer is 5 layers and the outer welding layer is 2 layers. Before welding starts, use a pipe cutter to make the male head of the welded joint. The outer layer of the conductor monofilament is 20mm shorter than the adjacent inner layer, and the two layers in the center are sawed flush. eventually into a ladder figure 2 As shown, and fasten each layer tightly. Use low-resistivity electrode A when welding the inner 5-layer conductor, and use high-resistivity electrode B when welding the outer 2-layer conductor. The production of the female head of the welded joint is carried out in conjunction with the male head. First, use a pipe cutter to cut the conductor on each layer. The outer layer of the conductor monofilament is 20mm longer than the adjacent inner layer, and the two layers in the center are sawed evenly. image 3 , Before welding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com