Tissue activity promotion type pulp capping agent and preparation method thereof

A pulp capping and active technology, applied in the field of tissue-promoting active pulp capping agent and its preparation, can solve the problems of inability to promote tissue activity, chronic persistent inflammation, root canal absorption, etc., so as to improve tissue recovery and promote repair , Improve the effect of repair performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

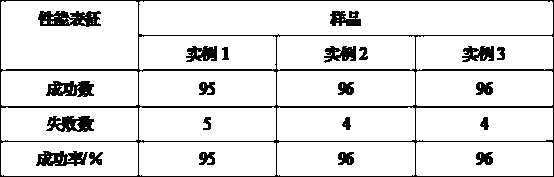

Examples

example 1

[0024] Take the vine and grind it through a 100-mesh sieve to obtain a ground powder, and mix the ground powder with a mass fraction of 75% ethanol solution at a mass ratio of 1:10, then heat and reflux at 75°C for 2 hours, then let it stand and cool to room temperature , filtered to obtain the filtrate and place it at 75°C for rotary evaporation to 1 / 5 of the volume of the filtrate to obtain a concentrated filtrate; in parts by weight, weigh 55 parts of deionized water, 10 parts of concentrated filtrate, 2 parts of OP-10, 1 part of ammonium persulfate, 10 parts of acrylamide, and 6 parts of sodium dodecylbenzenesulfonate were placed in a three-necked flask, stirred and mixed, and nitrogen gas was introduced to remove the air. The rate of nitrogen gas introduction was controlled at 45 mL / min. After the completion, it was left to stand for 20 minutes, then heated in a water bath at 45°C for 25 minutes, stirred and mixed, and allowed to stand for 20 hours to solidify to prepare a...

example 2

[0026] Take the vine and grind it through a 100-mesh sieve to obtain a ground powder, and mix the ground powder with a mass fraction of 75% ethanol solution at a mass ratio of 1:10, then heat and reflux at 77°C for 3 hours, then let it stand and cool to room temperature , filtered to obtain the filtrate and place it at 77°C for rotary evaporation to 1 / 5 of the volume of the filtrate to obtain a concentrated filtrate; in parts by weight, weigh 57 parts of deionized water, 12 parts of concentrated filtrate, 3 parts of OP-10, 2 parts of ammonium persulfate, 12 parts of acrylamide and 7 parts of sodium dodecylbenzenesulfonate were placed in a three-necked flask, stirred and mixed, and nitrogen gas was introduced to remove the air. The rate of nitrogen gas introduction was controlled at 45mL / min. After the completion, it was left to stand for 22 minutes, then heated in a water bath at 47°C for 27 minutes, stirred and mixed, and allowed to stand for 22 hours to solidify to prepare a ...

example 3

[0028] Take the vine and grind it through a 100-mesh sieve to obtain a ground powder, and mix the ground powder with a mass fraction of 75% ethanol solution at a mass ratio of 1:10, then heat and reflux at 80°C for 3 hours, then let it stand and cool to room temperature , filtered to obtain the filtrate and place it at 80°C for rotary evaporation to 1 / 5 of the volume of the filtrate to obtain a concentrated filtrate; in parts by weight, weigh 60 parts of deionized water, 15 parts of concentrated filtrate, 3 parts of OP-10, 2 parts of ammonium persulfate, 15 parts of acrylamide, and 8 parts of sodium dodecylbenzenesulfonate were placed in a three-necked flask, stirred and mixed, and nitrogen gas was introduced to remove the air. The rate of nitrogen gas introduction was controlled at 45 mL / min. After the completion, it was left to stand for 25 minutes, then heated in a water bath at 55°C for 30 minutes, stirred and mixed, and allowed to stand for 24 hours to solidify to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com