Black chokeberry powder micro-capsules and preparation technology thereof

A preparation process, the technology of Rowan black fruit, is applied in the field of preparation of Rowan black fruit powder, which can solve the problems of loss of anthocyanin height and instability of polyphenols, and achieve low production cost, good stability and water solubility Sexuality, the effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A preparation process of black fruit sorbus powder microcapsules, the steps are as follows:

[0035] The fresh fruit of Sorbus blackberry is cleaned and squeezed to obtain juice and pomace; 0.5% citric acid is added to the juice to protect the color, and the soluble solid content of the juice is determined a;

[0036] Add the wall materials as maltodextrin b and β-cyclodextrin c, a:b:c=1:1.5:0.2, dissolve the wall materials with an appropriate amount of water, and heat to 70℃ for gelatinization;

[0037] The juice and the wall material are passed through a 100-mesh sieve, mixed thoroughly and stirred for 10 minutes, and the total solid content concentration is 25%; the spray drying inlet air temperature is 150°C, and the outlet air temperature is 70°C.

Embodiment 2

[0038] Example 2 A preparation process of black fruit sorbus powder microcapsules, the steps are as follows:

[0039] The fresh fruit of Sorbus blackberry is cleaned and squeezed to obtain juice and pomace. Add water to the pomace, pomace: water=1:5, add 0.5% citric acid for color protection, add pectinase 0.1%, and stir at 50°C for 30 minutes ;

[0040] Add ethanol to the pomace aqueous solution to an ethanol concentration of 50%, ultrasonically treat for 30 minutes, and filter to remove insoluble substances;

[0041] Pass the juice and wall material through a 100-mesh sieve, mix thoroughly and stir for 10 minutes, and the total solids concentration is 25%; the spray drying inlet air temperature is 150°C, and the outlet air temperature is 70°C;

[0042] Continue to add water, color retention agent, and pectinase to the pomace and repeat the extraction three times, combine the filtrate, remove ethanol and part of the water by vacuum rotary evaporation at low temperature (48℃), concent...

Embodiment 3

[0045] Example 3 A preparation process of black fruit sorbus powder microcapsules, the steps are as follows:

[0046] The fresh fruit of Sorbus blackberry is cleaned and squeezed to obtain juice and pomace. Add 0.2% citric acid and 0.1% L-cysteine to the juice to protect the color. Determine the soluble solid content of juice a;

[0047] The wall material added is maltodextrin b, a:b=1:2. Use appropriate amount of water to dissolve the wall material and heat it to 70℃ to gelatinize;

[0048] The juice and the wall material are passed through a 100-mesh sieve, mixed thoroughly and stirred for 10 minutes, and the total solids concentration is 20%; the inlet air temperature of the spray drying is 142°C, and the outlet air temperature is 65°C.

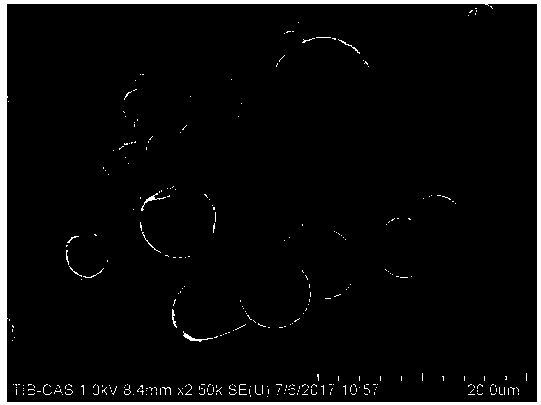

[0049] Such as figure 1 As shown, the obtained microcapsule powder has a smooth surface and no wrinkles, indicating that the protection of anthocyanins is better.

[0050] The present invention uses maltodextrin and β-cyclodextrin as the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com