Conical pipe anchor bar connection structure for prefabricated assembly structure

A technology for prefabricating and anchoring steel bars, applied in infrastructure engineering, bridge parts, bridge materials, etc., can solve the problems of prefabricated component size influence, corrugated pipe pull-out damage, large steel anchoring length, etc., to prevent pull-out, increase Tensile bearing capacity, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the connection structure of the tapered pipe anchoring steel bar and the node structure and construction of the tapered pipe preparation and the connection of the tapered pipe anchoring steel bar:

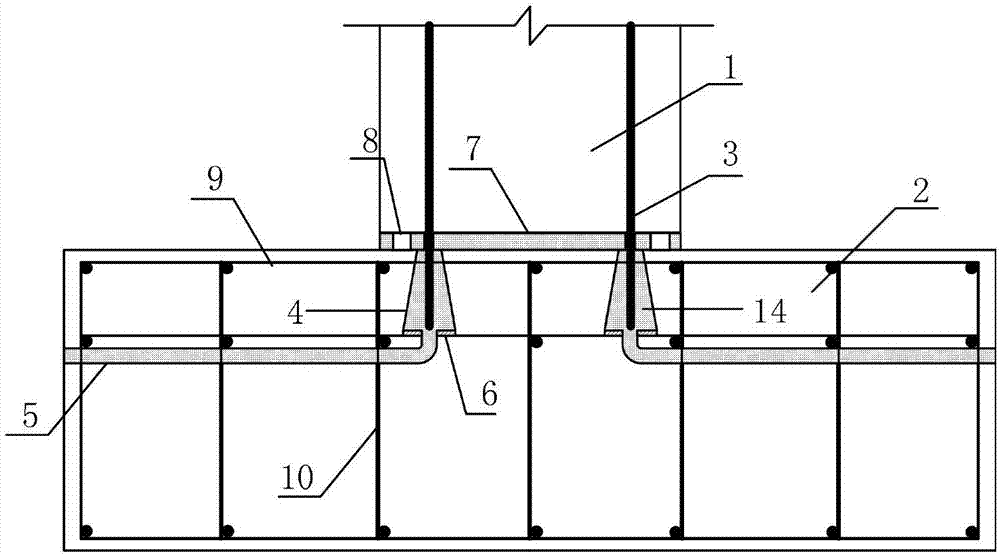

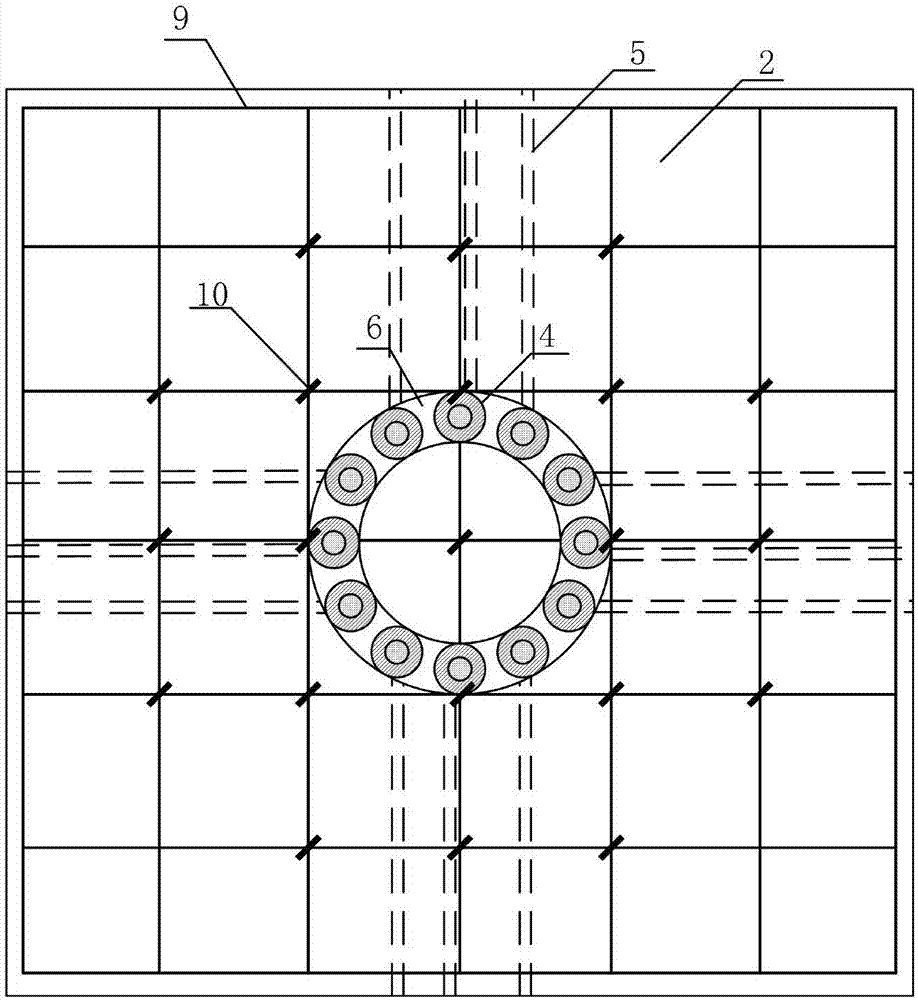

[0021] Such as figure 1 , 2 As shown, a tapered pipe anchoring steel bar connection structure for a prefabricated assembly structure, the connection structure includes a tapered pipe 4, a grouting pipe 5, and a tapered pipe fixing ring 6. The tapered tube 4 is a pre-embedded structure, and the tapered tube 4 can form a restraint effect on the steel bars and grouting material inside it, and at the same time can improve the tensile bearing capacity of the tapered tube 4 in the concrete. The erecting bars 9 and tie bars 10 in the prefabricated cap 2 also inhibit the cracking of the cap or foundation concrete when the tapered tube 4 is under tension.

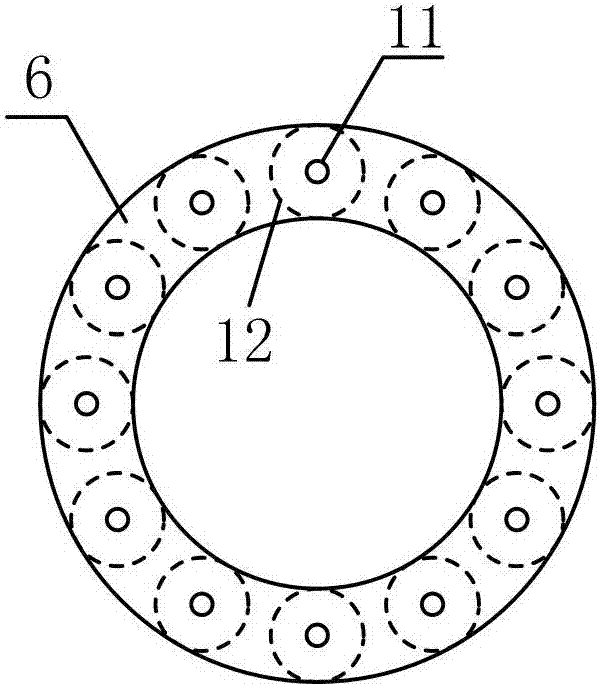

[0022] Such as image 3 As shown, the connection structure of the tapered pipe steel bar is: the tapered pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com