A kind of preparation method of liquid crystal ionomer intercalation montmorillonite composite material

A technology of intercalation montmorillonite and composite materials, which is applied in the field of preparation of liquid crystal ionomer intercalation montmorillonite composite materials, can solve the problems that the modification effect is difficult to achieve ideal, and the compatibility between polylactic acid and nucleating agent is poor. , to achieve the effect of improving thermal decomposition performance, improving compatibility and enhancing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

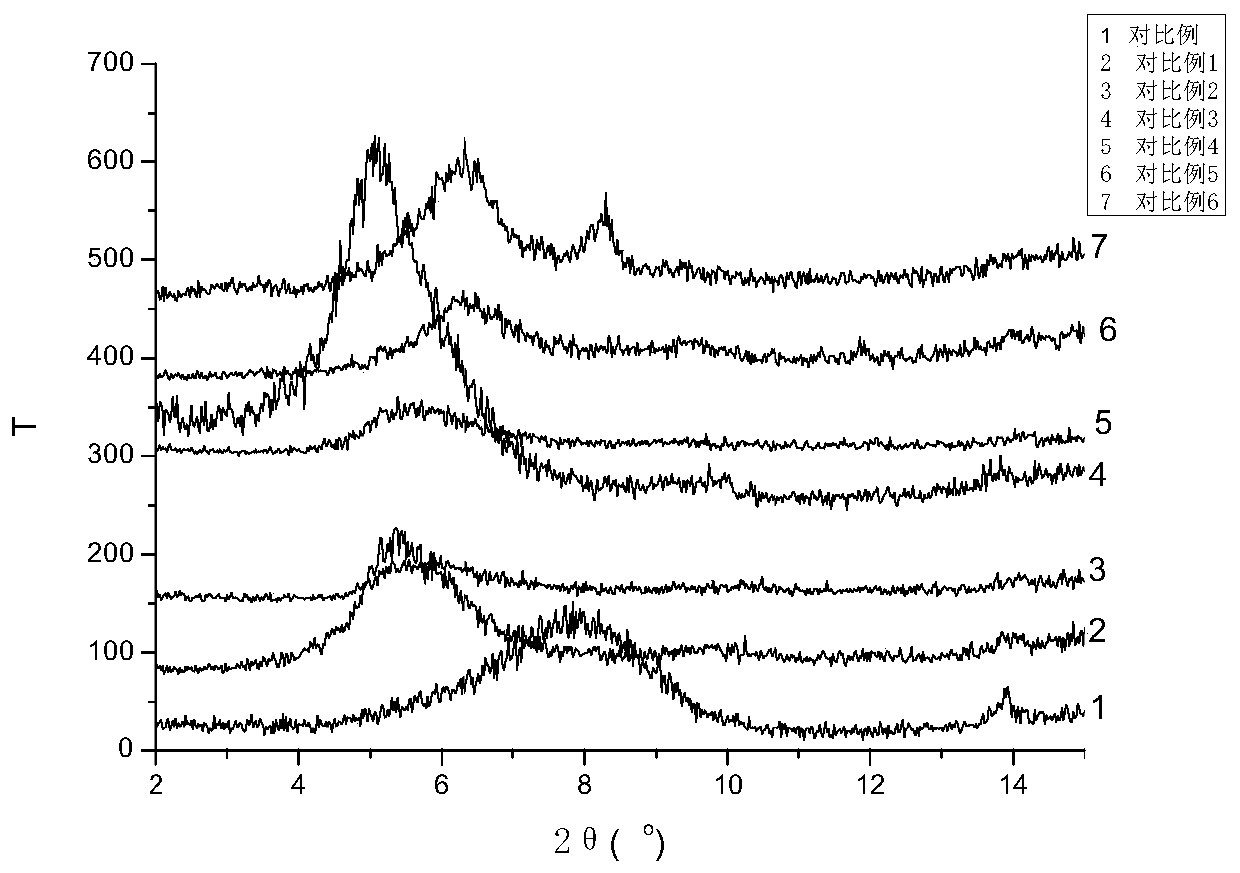

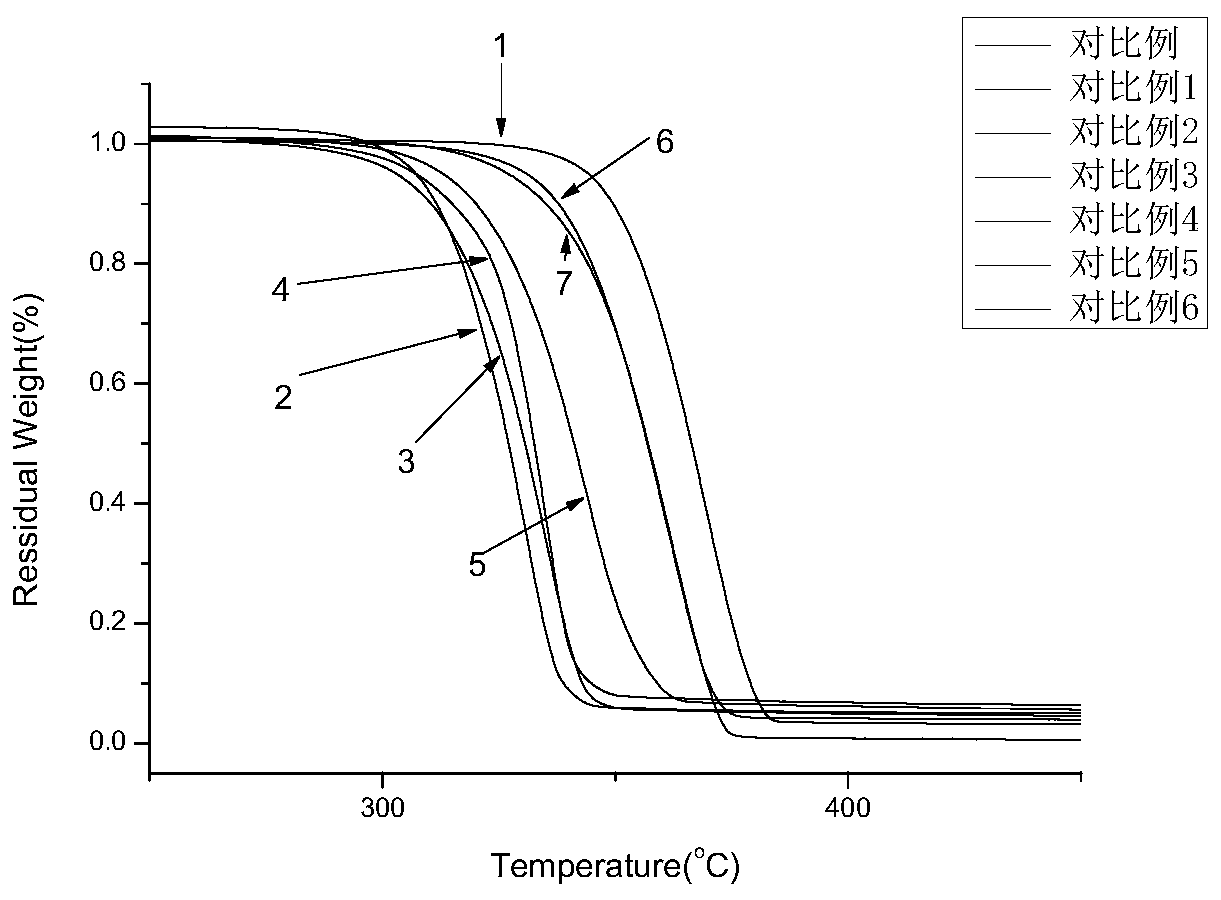

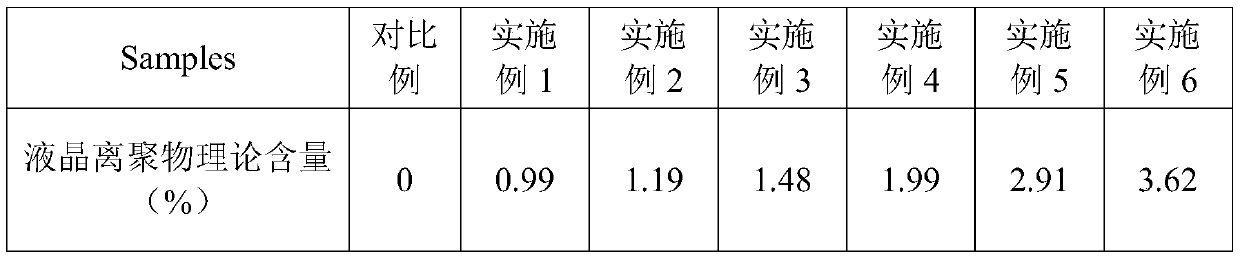

Examples

Embodiment 1

[0023] Add 100g of montmorillonite into a three-necked flask, add 300ml of ethanol solvent, and swell for 1 hour in a water bath at 75°C with a stirring speed of 600r / min; Ammonium bromide was added to the above reaction system, and reacted under the above reaction conditions for 6 hours; after the reaction was completed, stop heating and stirring, and after cooling to room temperature, the suspension was filtered with suction and washed several times with deionized water until it was washed with 0.1 mol / L AgNO 3 The solution was tested for the presence of halogen ions, and the resulting precipitate was transferred to a watch glass, dried in an oven at 75°C for 12 hours, ground, and passed through a 400-mesh sieve to obtain 80 g of organic montmorillonite.

[0024] Prepare the water phase: take 5.0g of organic montmorillonite, 0.3g of 4,4'dihydroxy α,α'dimethylbenzazine, 0.015g of bright yellow, 0.15g of sodium hydroxide, 0.03g of hexadecyltri Add methyl ammonium bromide into...

Embodiment 2

[0028] The difference from Example 1 is that when preparing the water phase, 7.5 g of the treated organic soil was taken, and 50 ml of deionized water was added.

Embodiment 3

[0030] The difference from Example 1 is that when preparing the water phase, 10 g of the treated organic soil was taken and 50 ml of deionized water was added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com