Testing method for dielectric property of liquid sample in high-pressure condition

A technology for liquid samples and dielectric properties. It is applied in the direction of dielectric property measurement, measurement of electricity, and measurement devices. It can solve problems such as temperature uncertainty and difficulty in estimating the effective electrode area, so as to reduce waste, isolate heat conduction, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

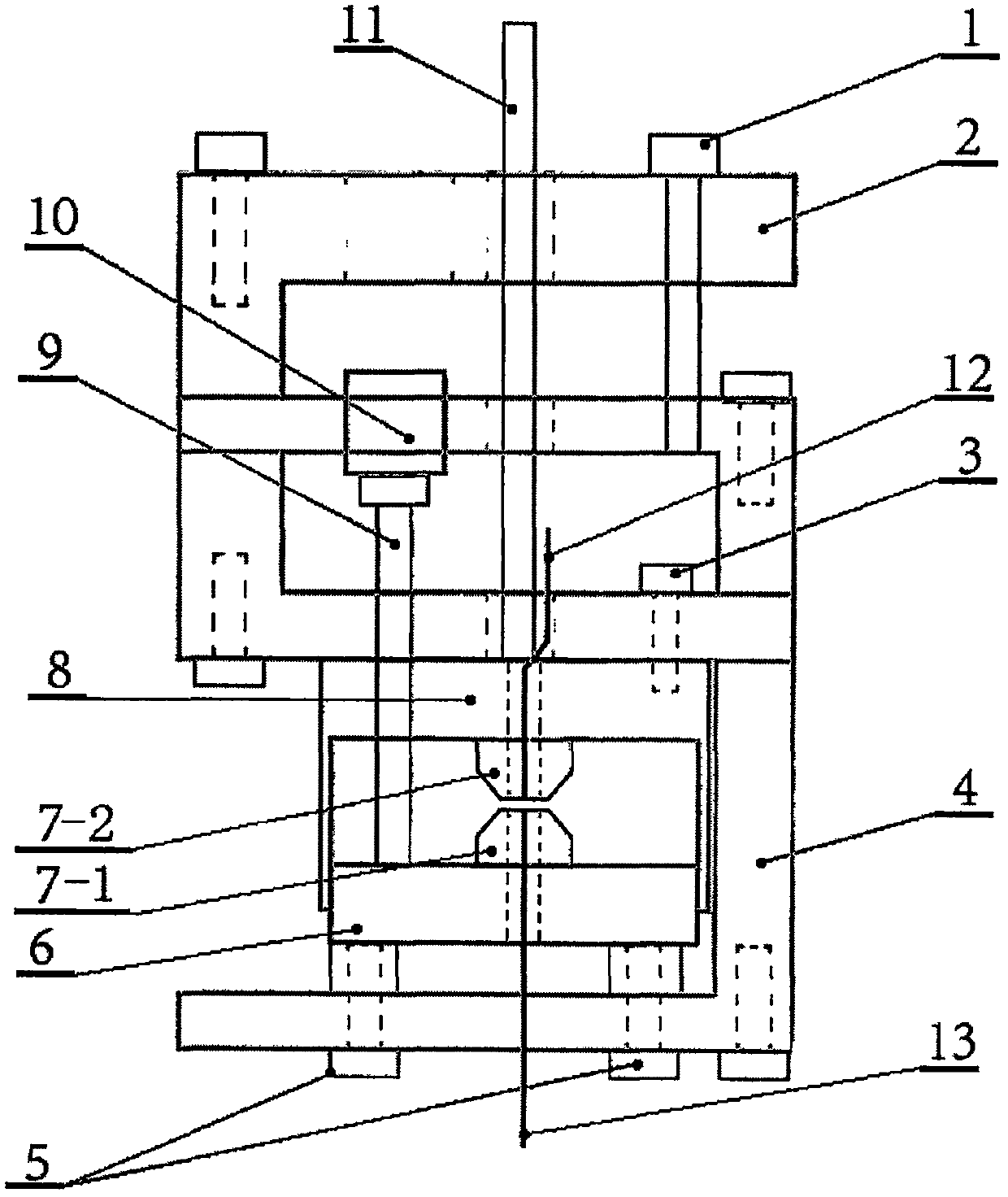

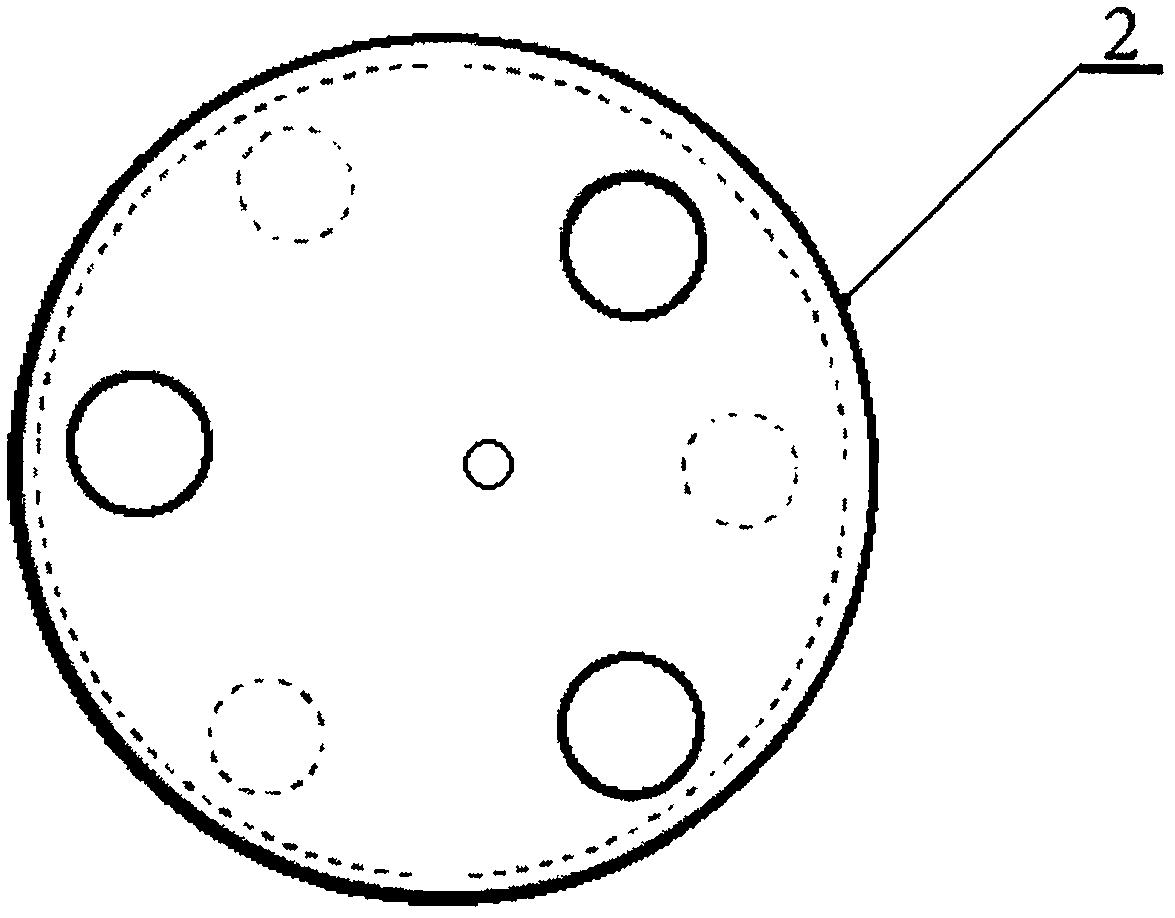

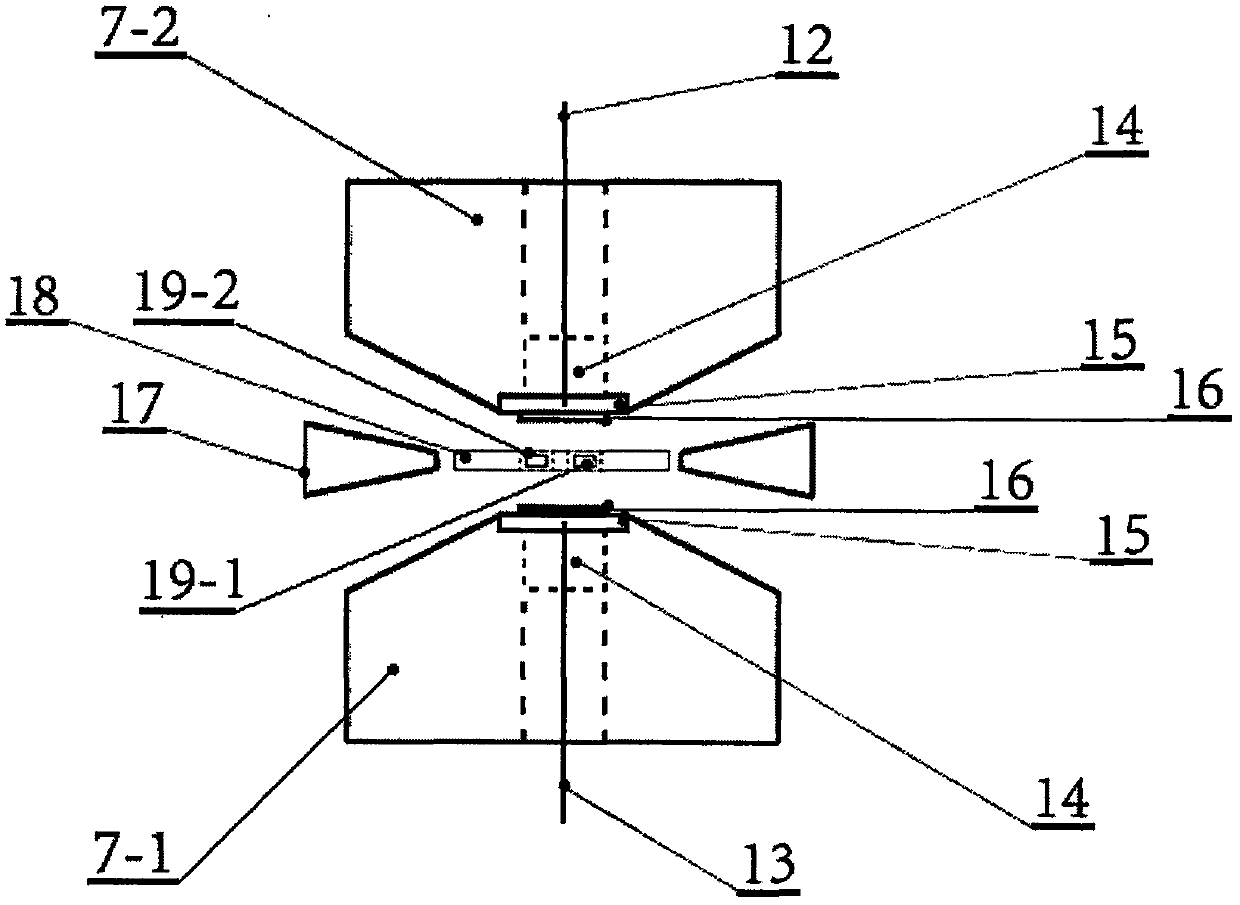

[0019] Such as figure 1 It is a schematic diagram of the structure of the present invention, such as figure 2 yes figure 1The top view schematic diagram, the device mainly includes screw rod I (1), support frame I (2), screw rod II (3), support frame II (4), support screw (5), piston part (6), lower anvil (7 -1), upper anvil (7-2), cylinder part (8), screw rod III (9), screw rod IV (10), optical fiber (11), current lead I (12), current lead II (13) , epoxy resin and diamond particle mixture (14), open common film (15), copper foil (16), indium gasket (17), Teflon gasket (18), sample, current lead III, current lead IV, current Lead V, current lead VI, dielectric constant measuring instrument, lock-in amplifier I, lock-in amplifier II, computer, the sample includes sample I (19-1) and sample II (19-2), and the support frame I (2) and support frame II (4) are all made up of upper support plate, lower support plate, connecting rod respectively, and the upper support plate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com