Production and processing method for edible camellia seed oil with low acid value and high quality

A technology of camellia seed oil and processing method, which is applied in the directions of fat oil/fat production, fat production, fat oil/fat refining, etc., can solve the problems of backward technology and equipment, low yield of oil products, and high preparation temperature, and avoid product oxidation. and rancidity, high oil yield and short life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

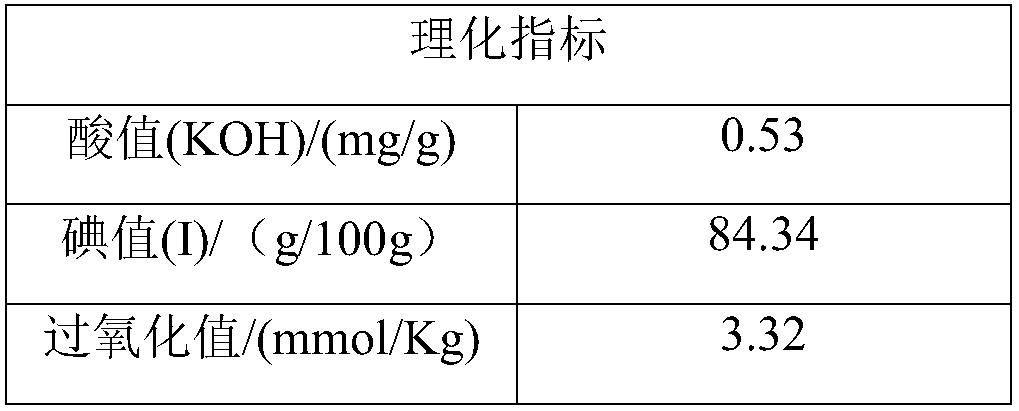

Embodiment 1

[0021] Pulverize the dehulled camellia oleifera seeds, pass through a 20-mesh sieve, weigh 500g of camellia oleifera seed powder, and add multi-stage separation supercritical CO 2 In the extraction equipment, set the extraction temperature to 40°C, the extraction pressure to 30MPa, the extraction time to 120min, the temperature of the separation kettle I to 45°C, the pressure of the separation kettle I to 10MPa, the temperature of the separation kettle II to 30°C, the pressure of the separation kettle II to 4MPa, and the temperature of the separation kettle III to 30°C 1. Separation kettle III pressure 4MPa carries out camellia seed oil extraction, and comesllia seed oil crude oil is obtained in separation kettle I.

[0022] Multistage separation of supercritical CO 2 The extracted camellia seed oil crude oil is added to the molecular distillation for refining treatment, the vacuum degree is set to 2Pa, the distillation temperature is 120°C, and the speed of the scraping film ...

Embodiment 2

[0030] Grind the dehulled camellia oleifera seeds, pass through a 40 mesh sieve, weigh 1000g of camellia oleifera seed powder, and add multistage separation supercritical CO 2 In the extraction equipment, set the extraction temperature to 45°C, the extraction pressure to 45MPa, the extraction time to 60min, the temperature of the separation kettle I to 50°C, the pressure of the separation kettle I to 16MPa, the temperature of the separation kettle II to 45°C, the pressure of the separation kettle II to 6MPa, and the temperature of the separation kettle III to 45°C 1. Separation kettle III pressure 6MPa carries out camellia seed oil extraction, and comesllia seed oil crude oil is obtained in separation kettle I.

[0031] Multistage separation of supercritical CO 2 The extracted camellia seed oil crude oil is added to the molecular distillation for refining treatment, the vacuum degree is set to 8Pa, the distillation temperature is 130°C, and the speed of scraping film is 250r·m...

Embodiment 3

[0039] Grind the dehulled camellia oleifera seeds, pass through a 60-mesh sieve, weigh 4000g of camellia oleifera seed powder, and add multi-stage separation supercritical CO 2 In the extraction equipment, set the extraction temperature to 50°C, the extraction pressure to 35MPa, the extraction time to 60min, the temperature of the separation kettle I to 60°C, the pressure of the separation kettle I to 20MPa, the temperature of the separation kettle II to 50°C, the pressure of the separation kettle II to 8MPa, and the temperature of the separation kettle III to 50°C 1. Separation kettle III pressure 8MPa carries out camellia seed oil extraction, and comesllia seed oil crude oil is obtained in separation kettle I.

[0040] Multistage separation of supercritical CO 2 The extracted camellia seed oil crude oil is added to the molecular distillation for refining treatment, the vacuum degree is set to 9Pa, the distillation temperature is 150°C, and the speed of the scraping film is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com