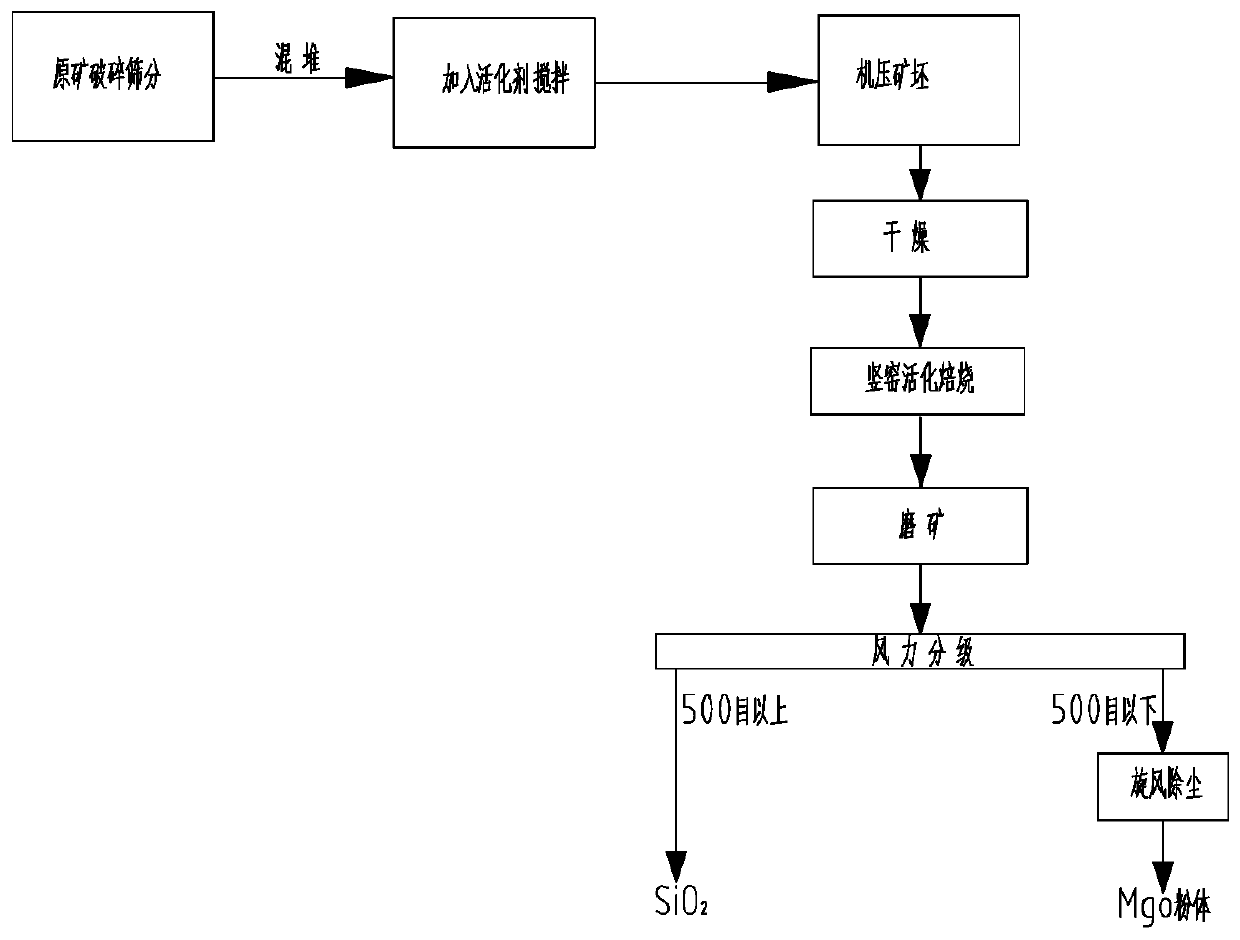

Magnesite activated-roasting, reselecting and silica-removing process

A magnesite and roasting technology, which is applied in the field of magnesite activation roasting gravity separation and silicon removal technology, can solve problems such as applications that are not suitable for industrial production, and achieve the effects of easy control of production process, simple process flow and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw ore of magnesite lean ore is taken from Zhengda Mine in Pailou, Haicheng. It is a third-grade magnesite ore with a MgO content of 46.0%, SiO 2 content of 2.5%, other impurities content of 0.7%;

[0028] 1) Set MgO content to 46.0%, SiO 2 The magnesite with a content of 2.5% is fed into the crushing and screening operation to obtain raw ore with a particle size of 0mm to 30mm;

[0029] 2) Add 9% magnesium oxide fine powder with a particle size of -325 mesh, 1% magnesium chloride and 10% water as an activator to the raw ore, stir evenly, and press it through a brick making machine under 2 atmospheric pressure. Billet;

[0030] 3) Put the billet into a drying oven at 160°C for 12 hours to dry and dehydrate;

[0031] 4) Put the dried slab with a moisture content of 5% into a shaft kiln at 950°C for 2.5 hours for activation and roasting, the MgCO in the slab 3 decomposed and activated to SiO 2 MgO powder with mineral particles dissociated, but still agglomerated...

Embodiment 2

[0036] The raw ore is taken from the flotation tailings of the Haicheng Magnesium Mine with a particle size greater than 200 mesh as raw materials, with MgO content of 44.0%, SiO 2 content of 5.7%, other impurities content of 1.8%.

[0037] 1) When MgO content is 44.0%, SiO 2 Add 8% magnesium oxide fine powder with a particle size of -325 mesh to the flotation tailings of Haicheng magnesium mine with a content of 5.7%, add 0.8% magnesium chloride and 12% water as an activator, stir evenly, Next, it is pressed into a billet by a brick making machine;

[0038] 2) Place the billet into a drying oven at 160°C for 12 hours to dry and dehydrate;

[0039] 3) Put the dried slab with a moisture content of 5% into a shaft kiln at 1000°C for activation and roasting for 2 hours, the MgCO in the slab 3 Activated with SiO 2 MgO powder with mineral particles dissociated, but still agglomerated with it; the activator of magnesium oxide, magnesium chloride and water added before magnesite ...

Embodiment 3

[0044] The raw ore of magnesite lean ore is taken from Jinding Huayu Mine in Haicheng, which is a third-grade magnesite ore with a MgO content of 45.8%, SiO 2 The content is 2.8%, and the content of other impurities is 0.6%.

[0045] 1) Set MgO content to 45.8%, SiO 2 The magnesite lean ore with a content of 2.8% is fed into the crushing and screening operation to obtain raw ore with a particle size of 0mm to 30mm;

[0046] 2) Add 9% magnesium oxide fine powder with a particle size of -325 mesh, 1% magnesium chloride and 10% water as an activator to the raw ore, stir evenly, and press it through a brick making machine under 2 atmospheric pressure. Billet;

[0047] 3) Put the billet into a drying oven at 160°C for 12 hours to dry and dehydrate;

[0048] 4) Put the dried slab with a moisture content of 5% into a shaft kiln at 1100°C for activation and roasting for 2 hours, the magnesite mineral MgCO in the slab 3 Activated with SiO 2 MgO powder with mineral particles dissoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com