Method for producing oxide particles

A technology of oxide particles and manufacturing methods, applied in the direction of ferrous oxides, chemical instruments and methods, iron oxide, etc., can solve the problem of not being able to obtain single crystal oxide particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0112] (Preparation of Oxide Raw Material Liquid / Preparation of Oxide Precipitation Solvent)

[0113] In the present invention, at least the oxide particle raw material is mixed with a solvent to dissolve or disperse the molecules in the solvent to prepare the oxide raw material liquid, and at least the basic substance is mixed with the solvent to dissolve or disperse the molecules In the solvent to prepare the oxide precipitation solvent. As a solvent to be used, for example, water and / or an organic solvent, or a mixed solvent composed of two or more of the above-mentioned solvents can be mentioned. Examples of the water include tap water, ion-exchanged water, pure water, ultrapure water, RO water, and the like, and examples of the organic solvent include alcohol compound solvents, amide compound solvents, ketone compound solvents, ether compound solvents, Aromatic compound solvents, carbon disulfide, aliphatic compound solvents, nitrile compound solvents, sulfoxide compound...

Embodiment

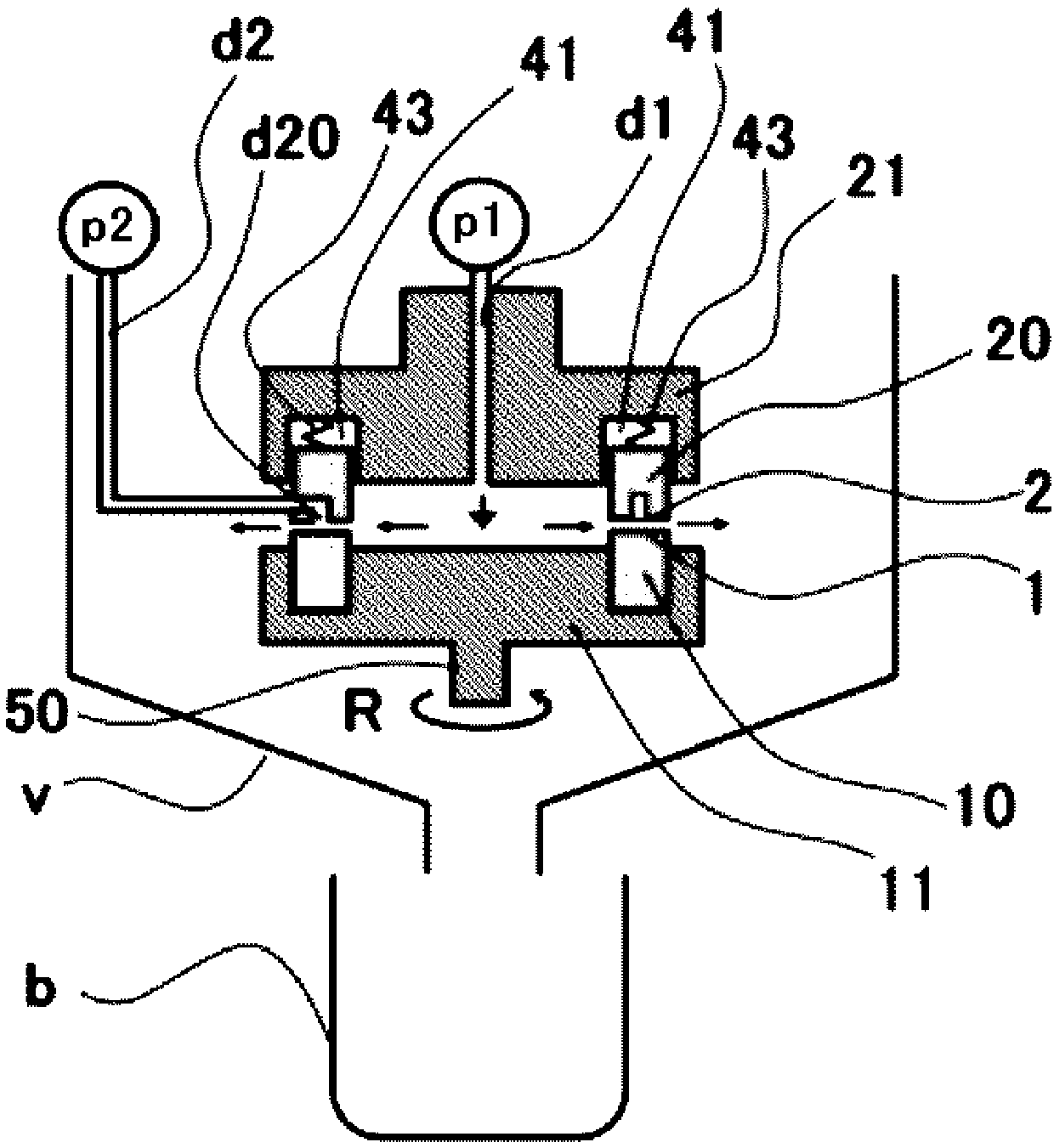

[0276] Hereinafter, the present invention will be further specifically described with reference to Examples. However, the present invention is not limited to the embodiments described later. In the following examples, liquid A refers to the figure 1 The first fluid to be treated introduced by the first introduction part d1 of the device shown in the figure, and the liquid B refers to the second fluid to be treated introduced from the second introduction part d2 of the same device.

[0277] (X) In the example of the production method of magnetite particles, (X) is added before the number of the example, and (Y) in the example of the production method of the cerium oxide particle, the number of the example is added before the number (Y), (Z) In the example of the manufacturing method of α-hematite particles, (Z) is added before the number of the example, and each example is specified. However, in Tables 1 to 5 and the general examples of the drawings, (X) (Y) (Z) are omitted....

Embodiment X1

[0281] Using Clearmix (product name: manufactured by LM-2.2S.Mtechnique), which is a high-speed rotating dispersing emulsifier, a magnetite precipitation solvent and a magnetite raw material solution were prepared, respectively.

[0282] Specifically, based on the composition ratio of the magnetite precipitation solvent shown in Example X1 of Table 1, an alkaline substance and pure water were mixed, and Clearmix was used, and the rotation speed of the rotor was 10,000 rpm and the preparation temperature was 45°C. Under stirring for 30 minutes, the mixture was uniformly mixed to prepare a magnetite precipitation solvent.

[0283] In addition, based on the mixing ratio of the magnetite raw material solution described in Example X1 of Table 1, the magnetite particle raw material and pure water were mixed, using Clearmix, the rotation speed of the rotor was 20000rpm, and the preparation temperature was 50°C. The mixture was uniformly mixed by stirring for 30 minutes under the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com