Pressure sensor, pressure sensor array and preparation method thereof

A pressure sensor and array technology, applied in the field of pressure sensors, can solve the problems of low sensing sensitivity, unsuitable for pressure sensing arrays, etc., and achieve the effect of improving sensitivity, changing threshold voltage, and small voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

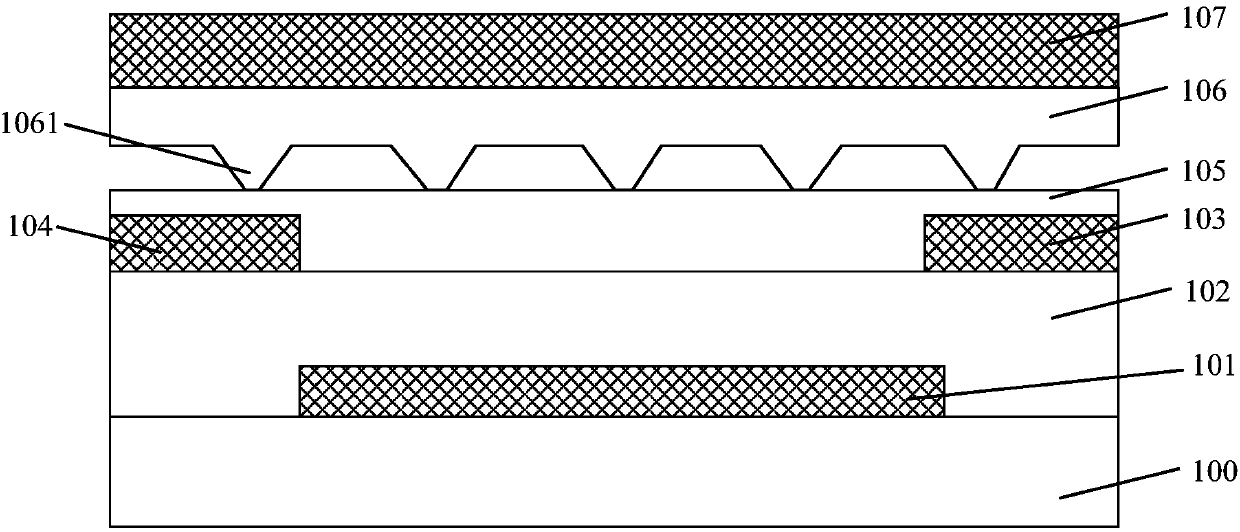

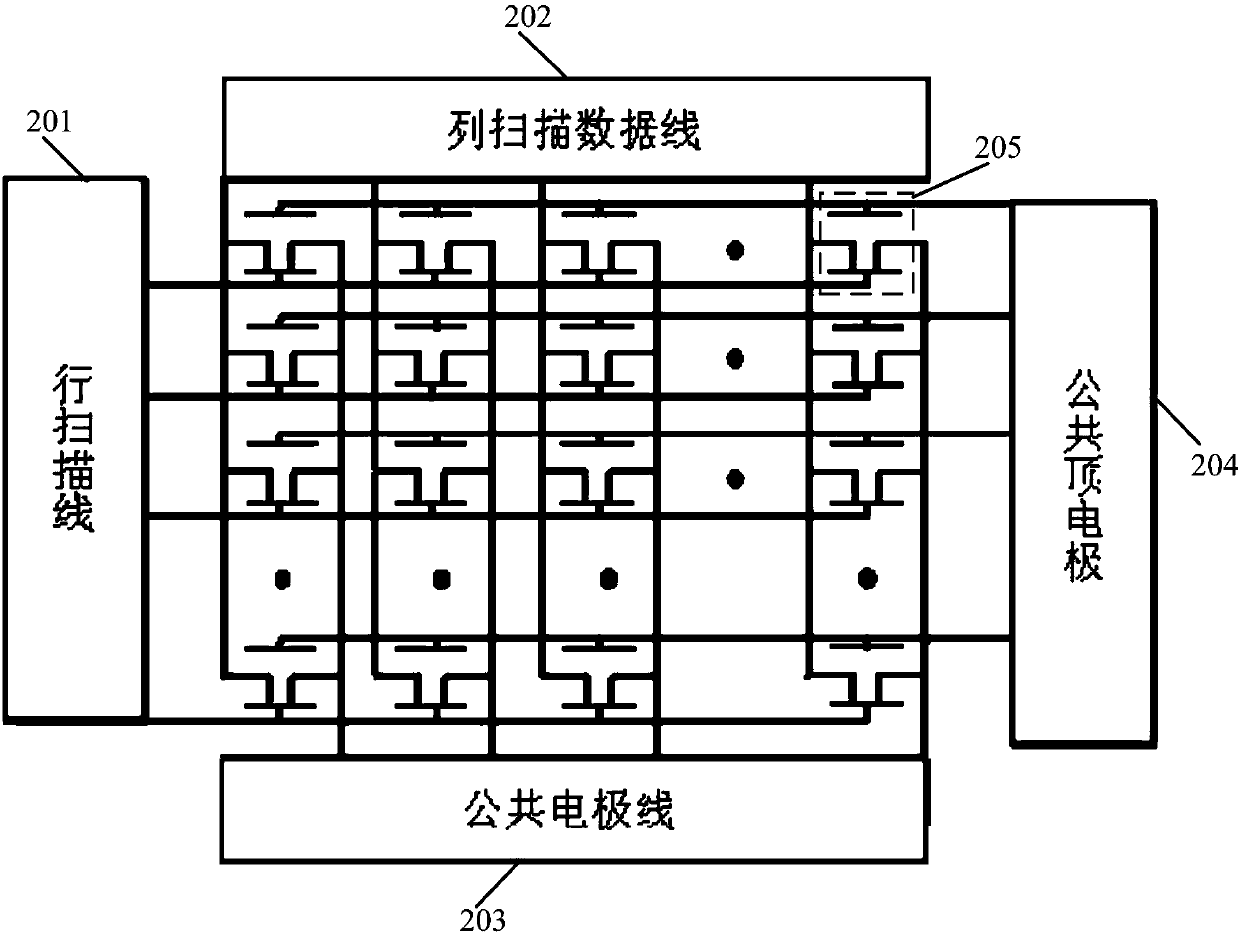

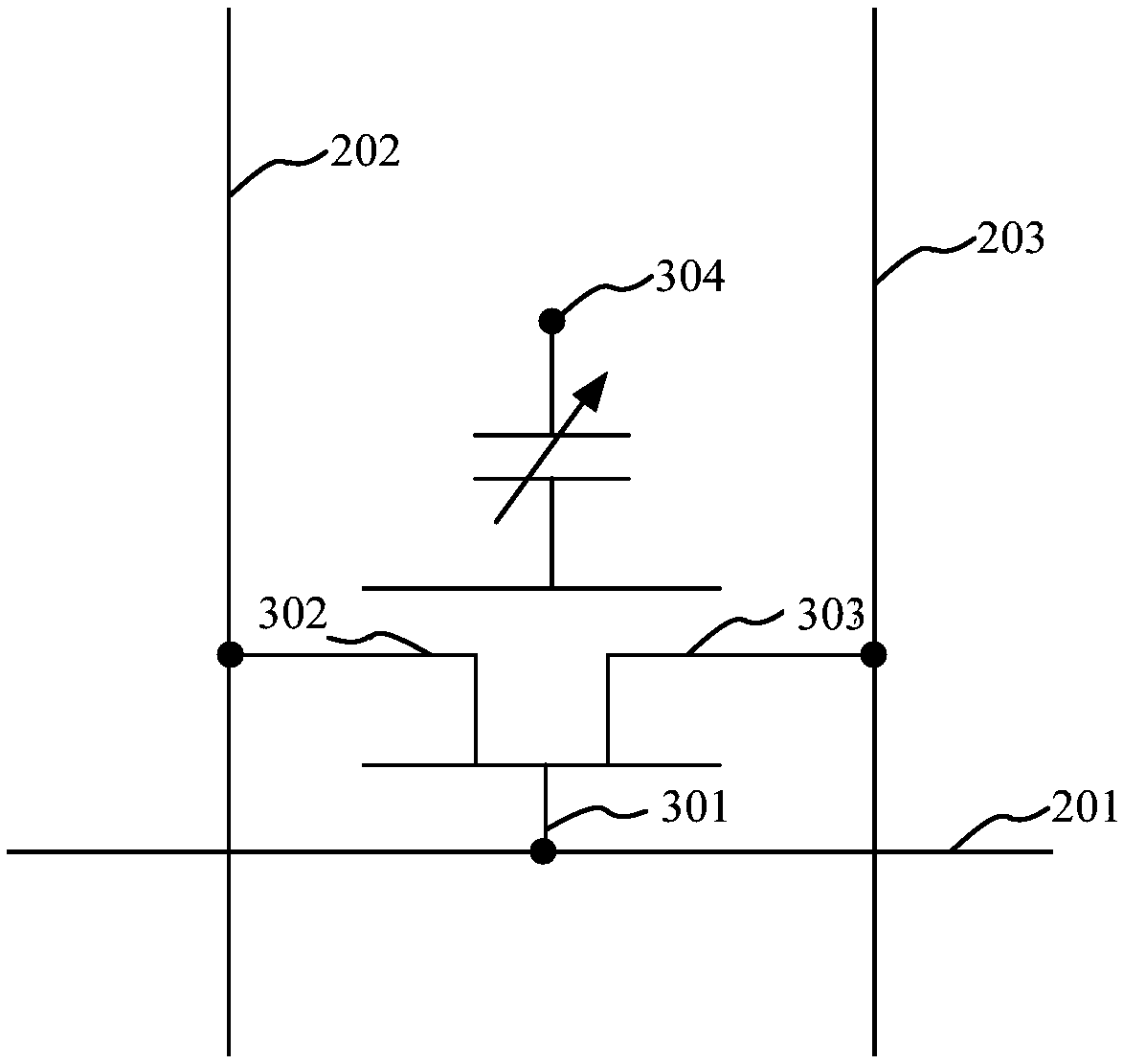

[0075] The pressure sensing array is completed through the following specific steps:

[0076] (1) Utilize ethanol solution, acetone solution and deionized water to carry out ultrasonic cleaning on the ethylene terephthalate (PET) substrate, dry after cleaning, and use oxygen plasma or ultraviolet light / ozone to treat the substrate surface;

[0077] (2) Prepare row scanning lines and gate electrodes of thin film transistor arrays on the substrate by means of vacuum evaporation;

[0078] (3) Preparing a PVC insulating layer film on the gate electrode by a spin-coating process, and then carrying out ultraviolet cross-linking heating and drying;

[0079] (4) Prepare column scanning data lines, common electrode lines, source electrodes and drain electrodes of the thin film transistor array on the substrate by means of vacuum evaporation;

[0080] (5) A layer of monomolecular layer PFBT is modified on the surface of the source electrode and the drain electrode of the thin film tran...

Embodiment 2

[0086] The pressure sensing array is completed through the following specific steps:

[0087] (1) Utilize ethanol solution, acetone solution and deionized water to ultrasonically clean the polyethylene naphthalate (PEN) substrate, dry after cleaning, and use oxygen plasma or ultraviolet light / ozone to treat the substrate surface;

[0088] (2) Prepare row scanning lines and gate electrodes of thin film transistor arrays on the substrate by means of inkjet printing;

[0089] (3) Prepare a polyvinylpyrrolidone (PVP) insulating layer film containing a crosslinking agent poly(melamine-co-formaldehyde) methanol (methylated polymelamine-co-formaldehyde) on the gate electrode by a spin coating process, and then perform ultraviolet crosslinking heating drying;

[0090] (4) Prepare column scanning data lines, common electrode lines, source electrodes and drain electrodes of the thin film transistor array on the substrate by means of inkjet printing;

[0091] (5) A layer of monomolecul...

Embodiment 3

[0097] The pressure sensing array is completed through the following specific steps:

[0098] (1) Utilize ethanol solution, acetone solution and deionized water to clean the polyimide (PI) substrate, dry it with dry nitrogen after cleaning, and use oxygen plasma or ultraviolet light / ozone to treat the substrate surface;

[0099] (2) Utilize conductive ink based on silver nanoparticles to prepare row scanning lines and gate electrodes of thin film transistor arrays on the substrate by inkjet printing;

[0100] (3) Preparing a polyvinyl alcohol (PVA) insulating layer film containing a cross-linking agent ammonium bichromate on the gate electrode by a spin-coating process, and then performing ultraviolet cross-linking heating and drying;

[0101] (4) Using conductive ink based on silver nanoparticles to prepare column scanning data lines, common electrode lines, source electrodes and drain electrodes of thin film transistor arrays on the substrate by inkjet printing;

[0102] (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com