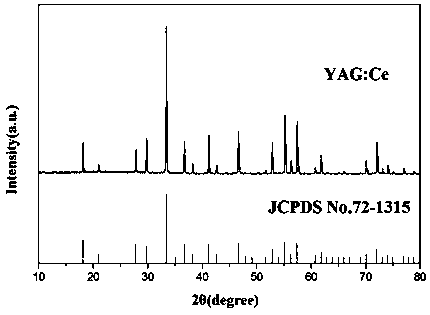

Preparation method of YAG: Ce fluorescent powder

A fluorescent powder, Y2O3 technology, applied in the chemical industry, can solve the problem of easy agglomeration and hardening of fluorescent powder, and achieve the effect of improving the reuse rate, high porosity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method that can significantly improve the porosity of YAG:Ce fluorescent powder of the present invention, specifically comprises the following steps:

[0021] Weigh Y according to the molar ratio Y:Al=0.6:1 2 o 3 、Al 2 o 3 , CeO 2 Doping ratio Y 2 o 3 、Al 2 o 3 0.06mol% of the sum of moles, H 3 BO 3 , CaCO 3 , NaF, and carboxymethyl cellulose additions were respectively Y 2 o 3 、Al 2 o 3 The sum of mass is 3wt%, 0.25wt%, 2wt%, 0.75wt%. Put all the reaction raw materials in the mixing bottle, add agate grinding beads and deionized water according to the ball: material mass ratio of 2:1 and water: material mass ratio of 3:1. The mixing bottle was placed in an ultrasonic instrument, sonicated at room temperature for 30 minutes, and then mixed for 5 hours. The water and materials were fully dried in a constant temperature drying oven at 85°C, passed through a 200-mesh sieve, then transferred to a small crucible, and placed in a large cr...

Embodiment 2

[0027] Weigh Y according to the molar ratio Y:Al=0.6:1 2 o 3 、Al 2 o 3 , CeO 2 The doping ratio is 0.06mol%, H 3 BO 3 , CaCO 3 , NaF, and carboxymethyl cellulose were added in amounts of 1wt%, 2wt%, 1wt%, and 2wt%, respectively. Put all the reaction raw materials in the mixing bottle, add agate grinding beads and deionized water according to the ball: material mass ratio of 2:1 and water: material mass ratio of 3:1. The mixing bottle was placed in an ultrasonic instrument, ultrasonicated for 20 minutes at room temperature, and then mixed for 10 hours. Fully dry the water and materials in a 60°C constant temperature drying oven, pass through a 200-mesh sieve, then transfer to a small crucible, and place it in a large crucible covered with reduced carbon powder. The crucible was placed in a rapid heating furnace and kept at 1450°C for 5 hours. The phosphor powder cooled to room temperature with the furnace was taken out, and after a little grinding, the YAG:Ce phosphor ...

Embodiment 3

[0029] Weigh Y according to the molar ratio Y:Al=0.6:1 2 o 3 、Al 2 o 3 , CeO 2 The doping ratio is 0.06mol%, H3 BO 3 , CaCO 3 , NaF, and carboxymethyl cellulose were added in amounts of 1wt%, 2wt%, 0.5wt%, and 3wt%, respectively. Put all the reaction raw materials in the mixing bottle, add agate grinding beads and deionized water according to the ball: material mass ratio of 2:1 and water: material mass ratio of 3:1. The mixing bottle was placed in an ultrasonic instrument, sonicated at room temperature for 30 minutes, and then mixed for 15 hours. Fully dry the water and materials in a 100°C constant temperature drying oven, pass through a 200-mesh sieve, then transfer to a small crucible, and place it in a large crucible covered with reduced carbon powder. The crucible was placed in a rapid heating furnace and kept at 1380°C for 8 hours. The phosphor powder cooled to room temperature with the furnace was taken out, and after a little grinding, the YAG:Ce phosphor powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com