Method for reinforcing silicone rubber by applying liquid crystal polymer microfibrillation

A technology of liquid crystal polymer and silicone rubber, which is applied in the field of rubber reinforcement, can solve the problems of low mechanical properties and achieve the effects of low thermal expansion coefficient, low density and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

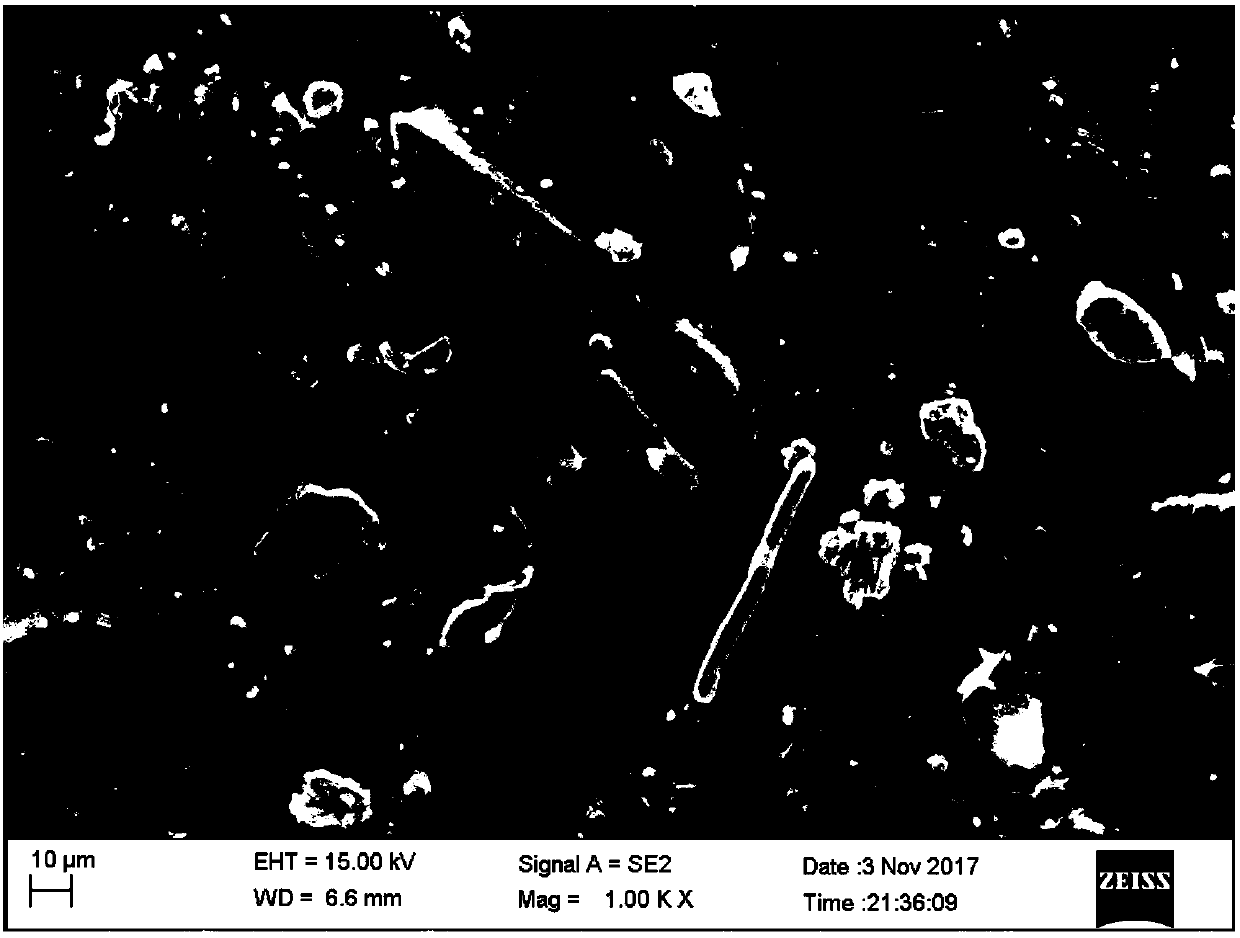

[0026] The liquid crystal macromolecule microfibrillation reinforced silicone rubber composite material of the present embodiment comprises 50 parts by mass of methyl vinyl silicone rubber, 50 parts by mass of methylphenyl vinyl silicone rubber, 30 parts by mass of fumed silica, Composed of 5 parts by mass of liquid crystal polymer and 2 parts by mass of dicumyl peroxide, the tensile strength of the molded product is 2.40 MPa, and the elongation at break is 251.06%. The SEM picture is as follows figure 1 shown, from figure 1 It can be seen that there is a fiber structure on the fracture surface of the liquid crystal polymer microfibrillated reinforced silicone rubber composite.

[0027] The preparation method of the liquid crystal polymer microfibrillation reinforced silicone rubber composite material in this embodiment is carried out according to the following steps:

[0028] (1) According to silicone rubber methyl vinyl silicone rubber, methyl phenyl vinyl silicone rubber, ...

Embodiment 2

[0034] The liquid crystal polymer microfibrillation reinforced silicone rubber composite material of the present embodiment comprises 50 parts by mass of methyl vinyl silicone rubber, 50 parts by mass of methylphenyl vinyl silicone rubber, 25 parts by mass of fumed silica, Composed of 10 parts by mass of liquid crystal polymer and 2 parts by mass of dicumyl peroxide, the tensile strength of the molded product is 2.29MPa, and the elongation at break is 218.92%.

[0035] The preparation method of the liquid crystal polymer microfibrillation reinforced silicone rubber composite material in this embodiment is carried out according to the following steps:

[0036] (1) According to silicone rubber methyl vinyl silicone rubber, methyl phenyl vinyl silicone rubber, fumed silica, benzoxazine resin, zirconium boride, carbon fiber and dicumyl peroxide;

[0037] (2) Firstly, masticate methyl vinyl silicone rubber and methyl phenyl vinyl silicone rubber to form wrapped rolls, add fumed whi...

Embodiment 3

[0042] The liquid crystal polymer microfibrillation reinforced silicone rubber composite material of the present embodiment comprises 50 parts by mass of methyl vinyl silicone rubber, 50 parts by mass of methylphenyl vinyl silicone rubber, 25 parts by mass of fumed silica, Composed of 15 parts by mass of liquid crystal polymer and 2 parts by mass of dicumyl peroxide, the tensile strength of the molded product is 2.07 MPa, and the elongation at break is 205.89%.

[0043] The preparation method of the liquid crystal polymer microfibrillation reinforced silicone rubber composite material in this embodiment is carried out according to the following steps:

[0044] (1) According to silicone rubber methyl vinyl silicone rubber, methyl phenyl vinyl silicone rubber, fumed silica, benzoxazine resin, zirconium boride, carbon fiber and dicumyl peroxide;

[0045](2) Firstly, masticate methyl vinyl silicone rubber and methyl phenyl vinyl silicone rubber to form wrapped rolls, add fumed whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com