Production process of flannel fabric

A production process, flannel technology, applied in the processing of textile materials, continuous processing of textile materials, biochemical treatment of enzymes/microorganisms, etc., can solve the problem of insufficient fluff on the surface of flannel fabrics, polyester fibers and Tencel Low fiber cashmere rate, poor flannel fabric quality and other problems, to achieve the effect of improving wearing comfort, fine pile, and white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

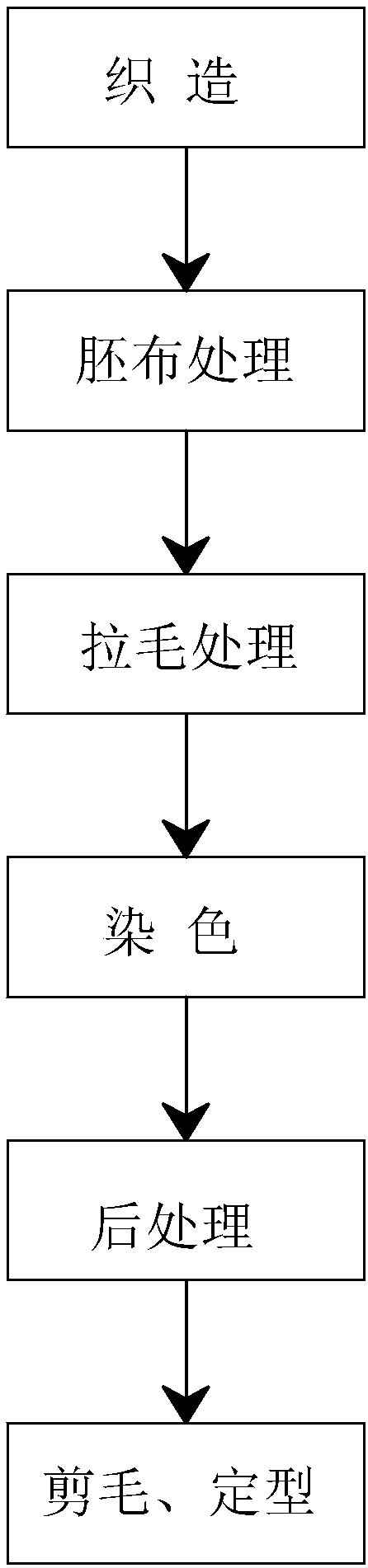

[0050] Such as figure 1 Shown, a kind of production technology of flannel fabric comprises the following steps:

[0051] (1) Weaving: the first yarn is used as warp yarn, the second yarn is used as weft yarn to interweave gray fabric, and the first yarn and the second yarn are blended with brucite fiber.

[0052] (2) Gray cloth treatment: impregnate the gray cloth with amylase. After dipping, put the gray cloth into the pool containing cellulase for soaking, so that the amylase and cellulase act on the gray cloth respectively. After soaking, wash it with water and wash it with sodium hydroxide deal with;

[0053] (3) Napping treatment: Napping the gray cloth so that the surface of the gray cloth is covered with fluff;

[0054] (4) Dyeing: Add dyes and dyeing auxiliaries to the dye vat, dyes include disperse dyes, dyeing auxiliaries include refining agent, penetrating agent, hydrogen peroxide and hydrogen peroxide stabilizer, heat to 110°C, keep for 40 minutes, slowly cool do...

Embodiment 2

[0065] The difference from Example 1 is: in step (4), heat to 140°C, keep for 30 minutes, slowly cool down to 60°C, and wash in water.

[0066] In step (5), the mass ratio of quaternary ammonium salt and amino silicone oil is 1:1.5.

[0067] The components contained in the first yarn and the weight percentage of each component are respectively: 10% wool fiber, 30% polyester fiber, 55% brucite fiber and 5% spandex fiber. Polyester fibers include squalene, which constitutes 6% by weight of polyester fibers.

[0068] The components contained in the second yarn and the percentage by weight of each component are: 25% wool fiber, 5% superfine fiber, 50% hollow polyester fiber and 20% brucite fiber. The fineness of microfiber is 0.15~0.3 denier.

[0069] The brucite fiber comprises 16-18%wt esters, and the esters include natural oils and synthetic esters, wherein the natural oils include soybean oil, and the content of natural oils accounts for 1-8% of the brucite fibers; Syntheti...

Embodiment 3

[0071] The difference from Example 1 is: in step (4), heat to 120°C, keep for 35 minutes, slowly cool down to 50°C, and wash in water.

[0072] The difference from Example 1 is that in step (5), the mass ratio of the quaternary ammonium salt to the amino silicone oil is 1:2.

[0073] The components contained in the first yarn and the weight percentage of each component are respectively: 8% wool fiber, 45% polyester fiber, 45% brucite fiber and 2% spandex fiber. Polyester fibers include squalene, which constitutes 7% by weight of polyester fibers.

[0074] The components contained in the second yarn and the percentage by weight of each component are: 20% wool fiber, 5% superfine fiber, 60% hollow polyester fiber and 15% brucite fiber. The fineness of microfiber is 0.15 denier.

[0075] The brucite fiber includes 16-18%wt of esters, and the esters include natural oils and synthetic esters, wherein the natural oils include corn oil, and the content of natural oils accounts for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com