High solid content organic matter hydrolysis acid production system and method

A technology for organic matter and hydrolysate, which is applied in biochemical equipment and methods, methods for stress-stimulated microbial growth, and post-processing of biomass, etc., which can solve problems such as difficulty in mass transfer, decrease in the efficiency and rate of hydrolysis of organic matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

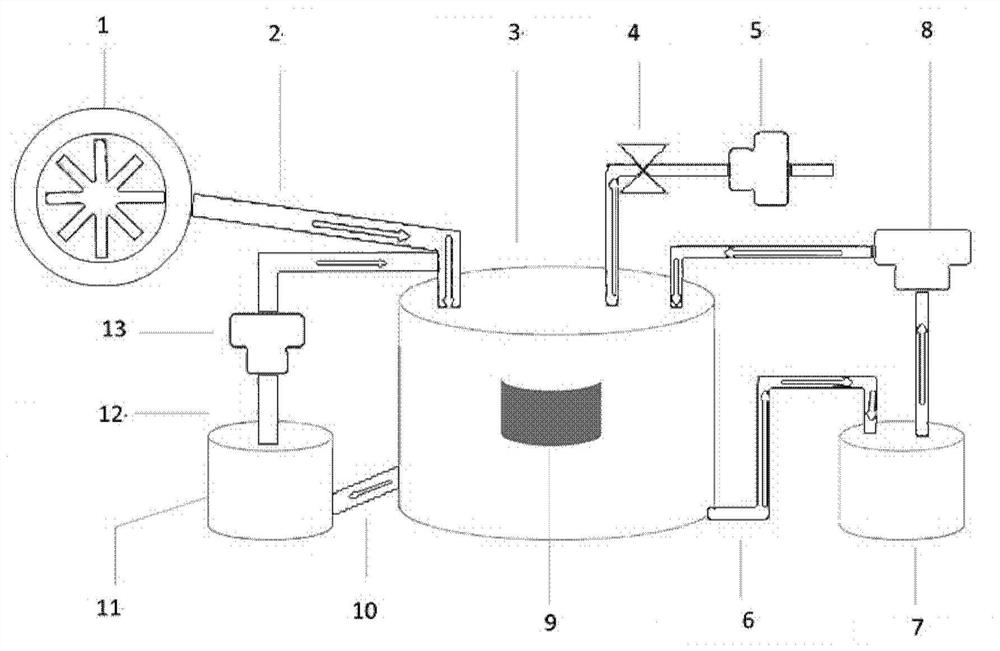

[0054] A high solid content organic matter hydrolysis acid generation system, its structure is as follows figure 1 Shown: including crushing device 1, feed pipe 2, vacuum air explosion device 3, valve 4, vacuum pump 5, hydrolyzate return pipe 6, hydrolyzate storage tank 7, hydrolyzate return pump 8, microwave device 9, hydrolyzate outlet 10. Hydrolyzate storage tank 11 , hydrolyzate return pipe 12 , hydrolyzate return pump 13 .

[0055] After the organic material is pulverized by the crushing device 1, it is transported to the vacuum air explosion device 3 through the feed pipe 2 to carry out the hydrolysis and acid production process of anaerobic fermentation. The diameter of the feed pipe 2 is 10-30 cm, preferably 15-20 cm. In this embodiment 15cm, the shape of the vacuum air explosion device 3 is a cylinder, and the inner wall is equipped with pH and temperature probes;

[0056]Before hydrolysis to produce acid, vacuum pump 5 is utilized to evacuate the vacuum air explosio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com