Waste grease device

A technology of waste grease and placement plate, which is used in the recovery of grease/fatty acid from waste, production of fat, and recovery of fatty substances. problems, to achieve the effect of reducing refining costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0024] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

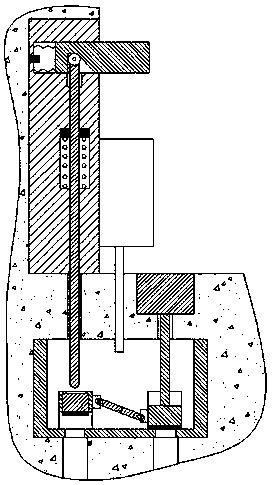

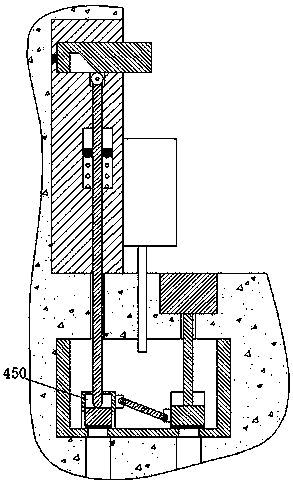

[0025] Such as Figure 1-5 As shown, a waste grease device of the device of the present invention includes a mounting plate 23 fixedly installed in the wall, a pouring pool 10 fixedly mounted on the right end of the mounting plate 23, and a flow guiding cylinder 16 fixedly mounted in the ground , the guide cylinder 16 is provided with an empty slot 32 with a notch facing upwards, and the pouring tank 10 is provided with a pouring port with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com