Method for treating nickel-iron slag and ceramic brick

A technology for nickel-iron slag and ceramic bricks, which is applied in the production, application, and household appliances of ceramic materials, can solve the problems of less comprehensive utilization, high cost, and complicated recovery of silicon and magnesium, and achieves the effect of broadening the utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

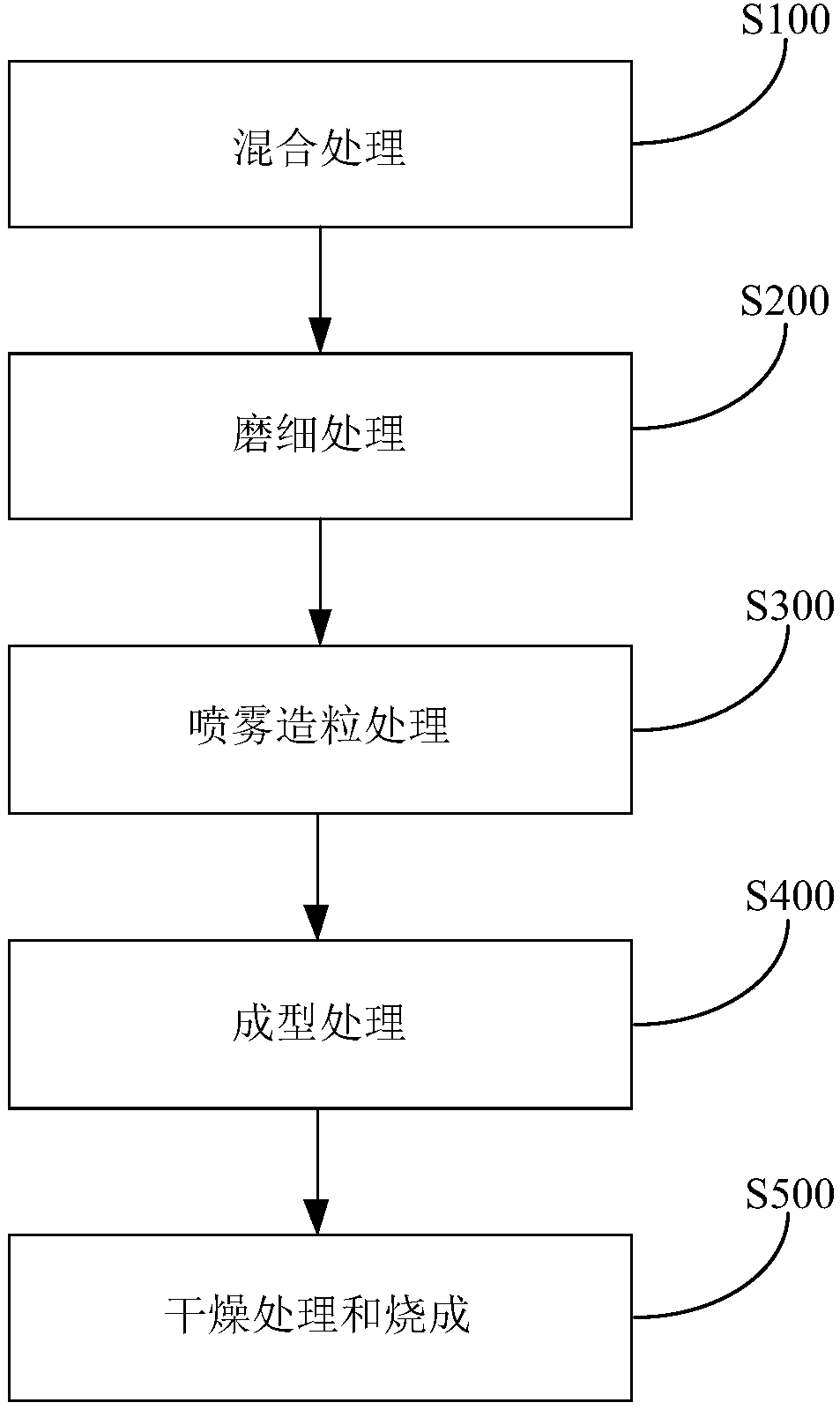

[0051] Follow the steps below to prepare ceramic tiles using ferronickel slag:

[0052] (1) Mix ferronickel slag, bentonite, silica and red mud slag in a mass ratio of 30:40:20:10.

[0053] The mass percentage of main components in ferronickel slag is CaO 8%, SiO 2 50%, MgO 20%, Al 2 o 3 5%, Cr 2 o 3 0.5%, NiO 0.2%, TFe 15%, (K 2 O+Na 2 O) 0.4%,

[0054] The mass percentage of the main component in bentonite is SiO 2 75%, Al 2 o 3 10%.

[0055] The mass percentage of the main component in silica is SiO 2 98%.

[0056] The mass percentage of the main components in red mud slag is CaO 10%, SiO 2 30%, Al 2 o 3 35%, (K 2 O+Na 2 O) 10%, TiO 2 6%, TFe 4%.

[0057] (2) Crushing and mixing the above-mentioned materials, transporting them into a ball mill for grinding treatment, so as to obtain powdery materials, and the mass percentage of powders with a particle size of not higher than 45 μm in the powdery materials is 90%.

[0058] (3) spraying and granul...

Embodiment 2

[0065] Follow the steps below to prepare ceramic tiles using ferronickel slag:

[0066] (1) Mix ferronickel slag, bentonite and silica according to the mass ratio of 70:20:10.

[0067] The main components in the ferronickel slag are CaO 10%, SiO 2 40%, MgO 30%, Al 2 o 3 1%, Cr 2 o 3 2%, NiO 0.1%, TFe 10%, (K 2 O+Na 2 O) 0.6%,

[0068] The mass percentage of the main component in bentonite is SiO 2 60%, Al 2 o 3 20%.

[0069] The mass percentage of the main component in silica is SiO 2 95%.

[0070] (2) Crushing and mixing the above-mentioned materials, transporting them into a ball mill for grinding treatment, so as to obtain powdery materials, and the mass percentage of powders with a particle size of not higher than 45 μm in the powdery materials is 90%.

[0071] (3) spraying and granulating the ground powdery material, the particle size of the obtained granular material is about 0.3mm, and the moisture content is 7wt%.

[0072] (4) The granular material ...

Embodiment 3

[0078] Follow the steps below to prepare ceramic tiles using ferronickel slag:

[0079] (1) Mix ferronickel slag, bentonite, silica and red mud slag at a mass ratio of 55:30:10:5.

[0080] The mass percentage of the main components in nickel-iron slag is CaO 9%, SiO 2 45%, MgO 25%, Al 2 o 3 3%, Cr 2 o 3 1%, NiO 0.15%, TFe 12%, (K 2 O+Na 2 O) 0.5%,

[0081] The mass percentage of the main component in bentonite is SiO 2 68%, Al 2 o 3 15%.

[0082] The mass percentage of the main component in silica is SiO 2 96%.

[0083] The mass percentage of the main components in the red mud slag is CaO 9%, SiO 2 25%, Al2O 3 40%, (K 2 O+Na 2 O) 9%, TiO 2 8%, TFe 3%.

[0084] (2) Crushing and mixing the above-mentioned materials, transporting them into a ball mill for grinding treatment, so as to obtain powdery materials, and the mass percentage of powders with a particle size not higher than 45 μm in the powdery materials is 87%.

[0085] (3) Spray granulating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com