An Equal Channel Angle Drawing Method for Efficient and Continuous Preparation of Ultra-fine-grained Pure Titanium at Room Temperature

A technology of equal channel corner and ultra-fine grain, applied in the direction of wire drawing die, etc., can solve the problems of low material utilization rate, difficult plastic deformation, limited material size, etc., to reduce drawing force and mold damage, reduce friction coefficient, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

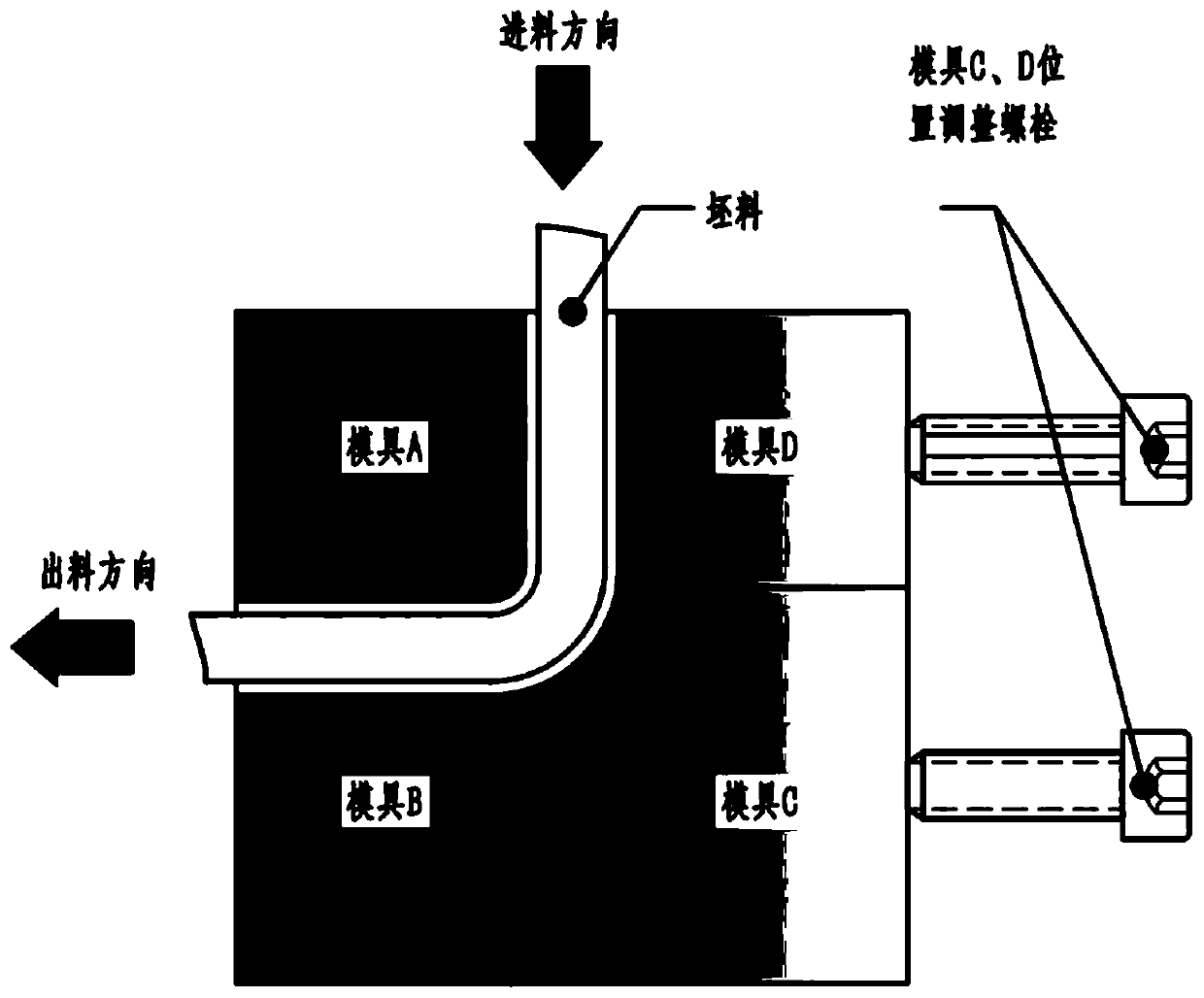

[0033] This embodiment provides an equal-channel corner drawing method for efficiently and continuously preparing ultra-fine-grained pure titanium at room temperature, which includes the following steps:

[0034](1) Using pure titanium (TA1) hot-rolled plate as the starting material, first anneal at a temperature of 500-700°C and a holding time of 0.5-3h, and then use wire cutting to obtain a billet with a cross-sectional size of 15mm×15mm as Workpiece to be processed, and according to the cross-sectional shape and size of the starting material, make an equal channel corner drawing die, wherein the equal channel corner channel section formed by the equal channel corner drawing die is a square, and the length and width of this square are 15mm;

[0035] (2) Grinding the surface of the billet after annealing with sandpaper, removing the surface scale, and coating lubricant graphite milk on its surface and the surface of 4 molds preformed equal channel corner channels, and the grap...

Embodiment 2

[0039] This embodiment provides an equal-channel corner drawing method for efficiently and continuously preparing ultra-fine-grained pure titanium at room temperature, which includes the following steps:

[0040] (1) Using pure titanium (TA1) hot-rolled plate as the starting material, first anneal at a temperature of 500-700°C and a holding time of 0.5-2h, and then use wire cutting to obtain a billet with a cross-sectional size of 10mm×10mm as Workpiece to be processed, and according to the cross-sectional shape and size of the starting material, make an equal channel corner drawing die, wherein the equal channel corner channel section formed by the equal channel corner drawing die is a square, and the length and width of this square are 15mm;

[0041] (2) Grinding the surface of the billet after annealing with sandpaper, removing the surface scale, and coating lubricant graphite milk on its surface and the surface of 4 molds preformed equal channel corner channels, and the gra...

Embodiment 3

[0045] This embodiment provides an equal-channel corner drawing method for efficiently and continuously preparing ultra-fine-grained pure titanium at room temperature, which includes the following steps:

[0046] (1) Using pure titanium (TA1) extruded rods with a diameter of 6mm as the starting material, first anneal at a temperature of 500-700°C and a holding time of 0.5-5h, and according to the cross-section of the starting material Shape and size Make equal-channel corner drawing dies, wherein the cross-section of the equal-channel corner channels formed by the medium-channel corner drawing dies is circular, and the diameter of the circle is 6mm;

[0047] (2) Grinding the surface of the billet after annealing with sandpaper, removing the surface scale, and coating lubricant graphite milk on its surface and the surface of 4 molds preformed equal channel corner channels, and the graphite milk is graphite for industrial wire drawing Milk, the main component of which is about 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com