Hole bottom fixing device of deformed measuring rod in rock borehole

A fixing device and a technology in the borehole, which is applied in the field of geotechnical engineering, can solve the problems of poor anti-corrosion ability of the fixing device, resistance to groundwater corrosion, limited anti-vibration ability of fixing claws, etc., to achieve reliable long-term anchoring anti-vibration and improve anti-corrosion performance, reliable corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

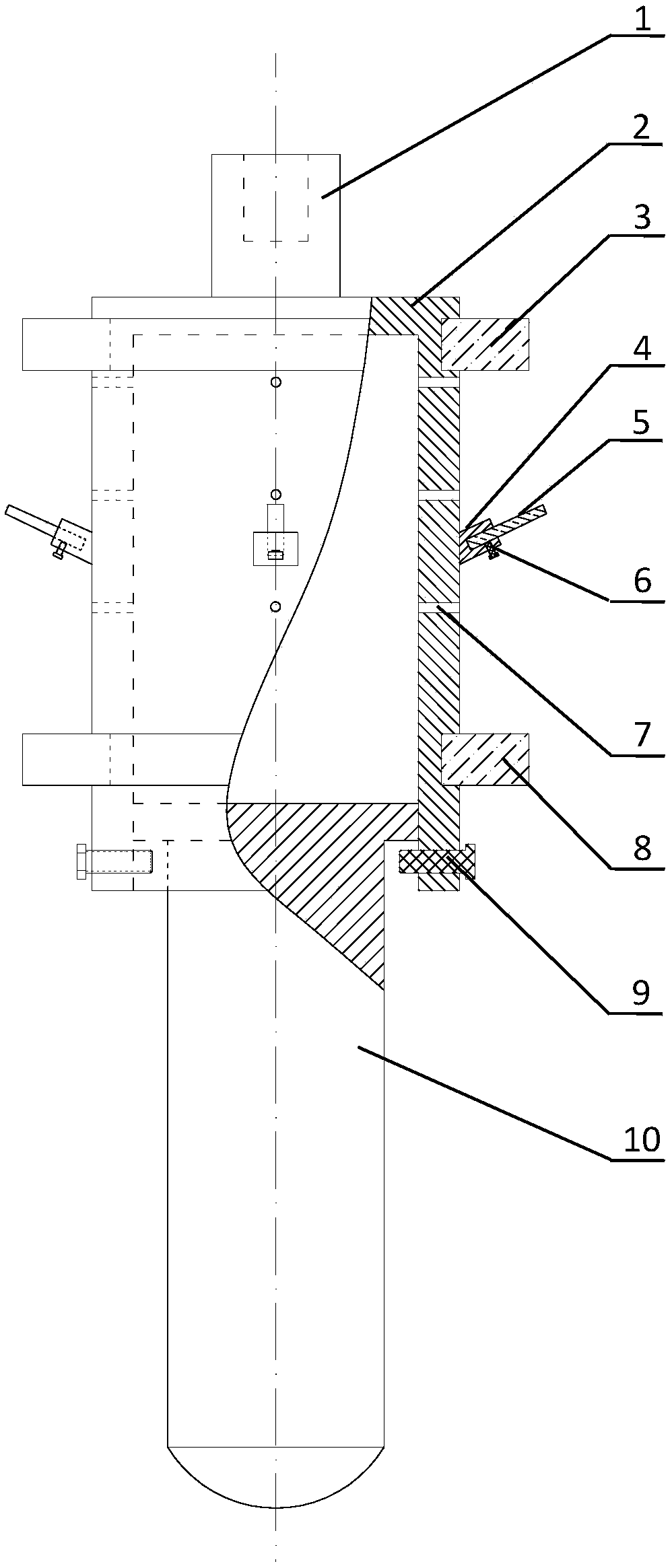

[0027] (1) Measure the outer diameter D of the first stopper 3 of the device 0 =78mm, so this kind of drilling is designed to drill the hole diameter D 1 =76mm, the elastic spines 5 are loaded into the spine seat 4, and the position of the elastic spines 5 in the inner hole of the spine seat 4 is adjusted through the fixing screw 6, so that the distance L between the outer endpoints of the two elastic spines 5 arranged symmetrically at 180° 1 is 90mm.

[0028] (2) The length of the inner cavity of the slurry-holding chamber 2 is measured to be 400 mm, and the test shows that the exposed length of the piston push rod 10 at the lowermost end of the slurry-containing cavity 2 is greater than that when the piston push rod 10 is pushed to the uppermost end surface of the slurry-containing cavity 2 length.

[0029] (3) Before the fixing device is placed on site, use paraffin to block the twelve slurry discharge holes 7 of the slurry chamber 2, and then release the clamping screw 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com