High-efficient water reducing agent

A high-efficiency water-reducing agent and vitamin technology, which is applied in the field of concrete admixtures, can solve the problems of complicated preparation steps and difficult process control of the water-reducing agent, and achieve the effects of easy acquisition, wide application and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

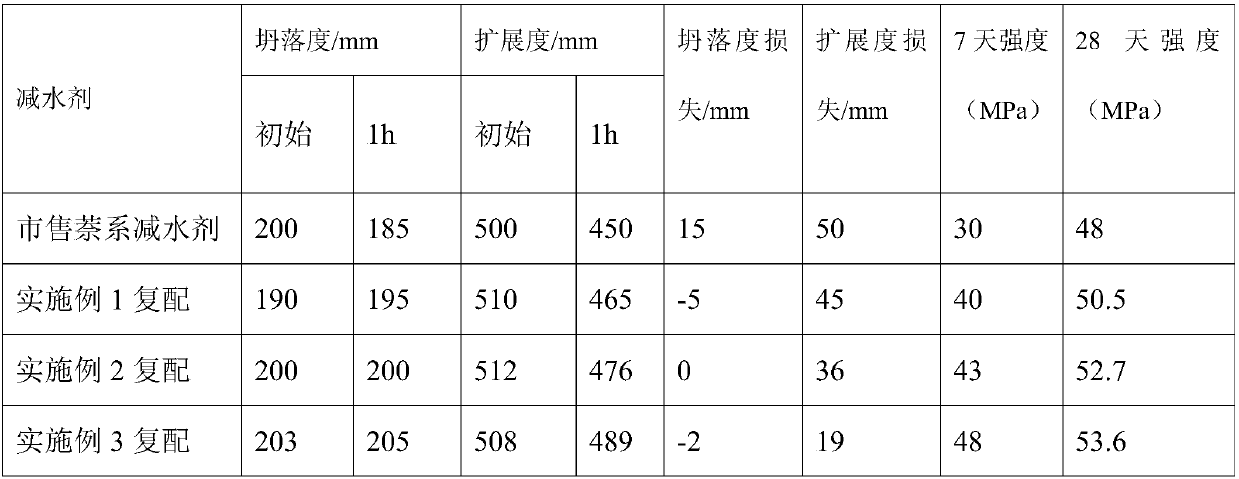

Examples

Embodiment 1

[0024] Measure 90Kg of polyethylene glycol monomethyl ether, 50Kg of maleic rosin, 25Kg of phthalic anhydride, and 10Kg of sodium p-styrenesulfonate into the reactor, add 50Kg of ultrapure water, and stir evenly; the temperature in the reactor is kept at 70°C, React for 3 hours; slowly add 1L of concentrated sulfuric acid dropwise to the reactor, then add and stir for 0.5 hours, keep warm for 30 minutes; take vitamin c15Kg, vitamin e5Kg, vitamin b15Kg, azobisisoheptanonitrile 10Kg, Add 25Kg of dimethyl ester and 25Kg of ammonium persulfate into ultrapure water, heat to 75°C to make solution A; slowly add solution A to the reaction kettle for 2.5 hours, stir evenly, add foaming agent to react for 12 minutes, and then add Antifoaming agent, react for 3 hours, cool to room temperature; adjust the pH of the material to 6.8-7.0 with sodium hydroxide solution to obtain a high-efficiency water reducer.

Embodiment 2

[0026] Measure 90Kg of polyethylene glycol monomethyl ether, 50Kg of maleic rosin, 25Kg of phthalic anhydride, and 10Kg of sodium p-styrenesulfonate into the reactor, add 50Kg of ultrapure water, and stir evenly; the temperature in the reactor is kept at 70°C, React for 3 hours; slowly add 1L of concentrated sulfuric acid dropwise to the reactor, then add and stir for 0.5 hours, keep warm for 30 minutes; take vitamin c15Kg, vitamin e5Kg, vitamin b15Kg, azobisisoheptanonitrile 10Kg, Add 25Kg of dimethyl ester and 25Kg of ammonium persulfate into ultrapure water, heat to 75°C to make solution A; slowly add solution A to the reaction kettle for 2.5 hours, stir evenly, add foaming agent to react for 12 minutes, and then add Modified silicone defoamer, react for 3 hours, cool to room temperature; use sodium hydroxide solution to adjust the pH of the material to 6.8-7.0 to obtain a high-efficiency water reducer.

[0027] Among them, the preparation method of the modified silicone de...

Embodiment 3

[0029] Measure 100Kg of polyethylene glycol monomethyl ether, 80Kg of maleic rosin, 35Kg of phthalic anhydride, and 13Kg of sodium p-styrenesulfonate into the reactor, add 120Kg of ultrapure water, and stir evenly; the temperature in the reactor is kept at 80°C, React for 4 hours; slowly add 1.5L concentrated sulfuric acid to the reaction kettle, stir while adding, take 1 hour, keep warm for 30 minutes; take 15Kg vitamin c, 5Kg vitamin e, 15Kg vitamin b, 10Kg azobisisoheptanonitrile, Add 25Kg of dimethyl ester and 25Kg of ammonium persulfate into ultrapure water, heat to 75°C to make solution A; slowly add solution A to the reaction kettle for 3 hours, stir evenly, add foaming agent to react for 30 minutes, and then add disinfectant Foaming agent, react for 3 hours, cool to room temperature; adjust the pH of the material to 6.8-7.0 with sodium hydroxide solution to obtain a high-efficiency water reducer.

[0030] Among them, the preparation method of the modified silicone defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com