Light-emitting diode and manufacturing method thereof

A technology of a light-emitting diode and a manufacturing method, which is applied in the field of optoelectronics, can solve the problems of increased cost and complicated LED manufacturing process, and achieves the effect of saving material cost, reducing the cost of lithography process, and saving the lithography process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] As mentioned in the background technology section, adding a current spreading layer in the prior art can improve the luminous efficiency of the LED chip, but it will lead to a complicated manufacturing process of the LED chip and increase the manufacturing cost.

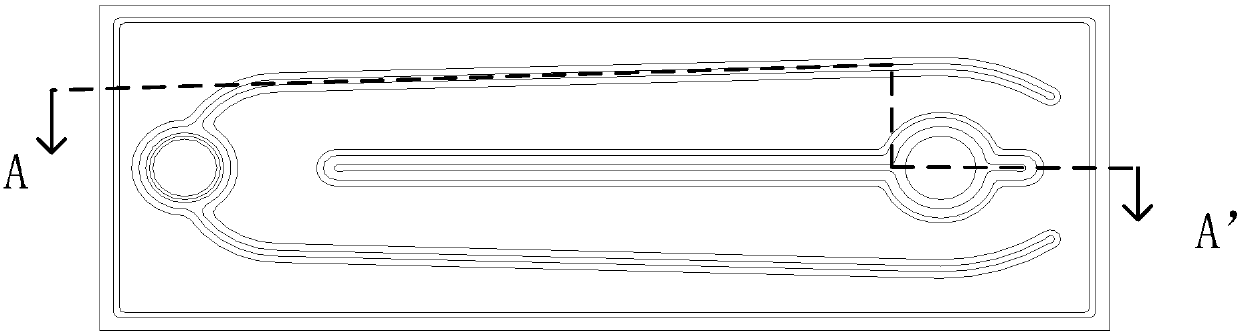

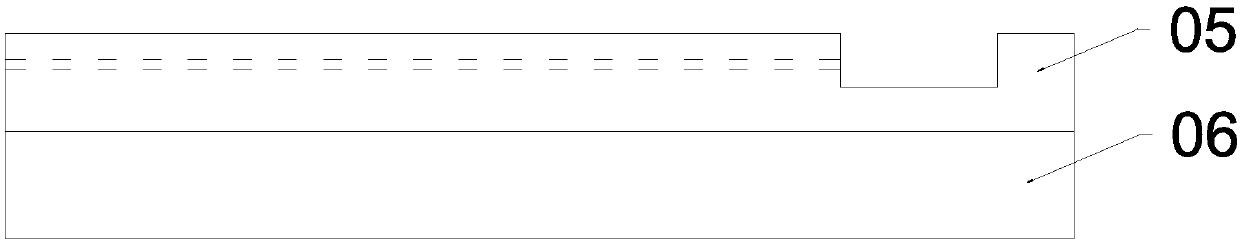

[0055] Specifically, such as figure 1 and figure 2 As shown, among them, figure 1 It is a schematic top view structural diagram of an LED chip in the prior art; figure 2 for along figure 1 The cross-section of the line AA' in the middle is a schematic diagram of the LED chip structure after adding a current blocking layer in the prior art; the LED chip includes a substrate 06, an epitaxial structure 05 grown on the substrate 06, a current blocking layer 01, a transparent conductive Layer 02, metal electrodes (03A and 03B) and passivation protection layer 04, which mainly prevent electrons / holes from recombining under the metal electrode 03 by providing an insulating current blocking layer 01 under the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com