Bionic vertex face heat conduction enhancement filler, preparation method and application in PBX (polymer bonded explosive)

A technology of thermal conductivity enhancement and thermal conductivity filler, which is applied in non-explosive fillers/gelling agents/thickeners, offensive equipment, explosives processing equipment, etc., which can solve problems such as uneven thermal expansion, affecting the reliability of weapon systems, and unfavorable heat transfer. , to achieve the effects of reducing thermal stress, good thermal conductivity, and enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

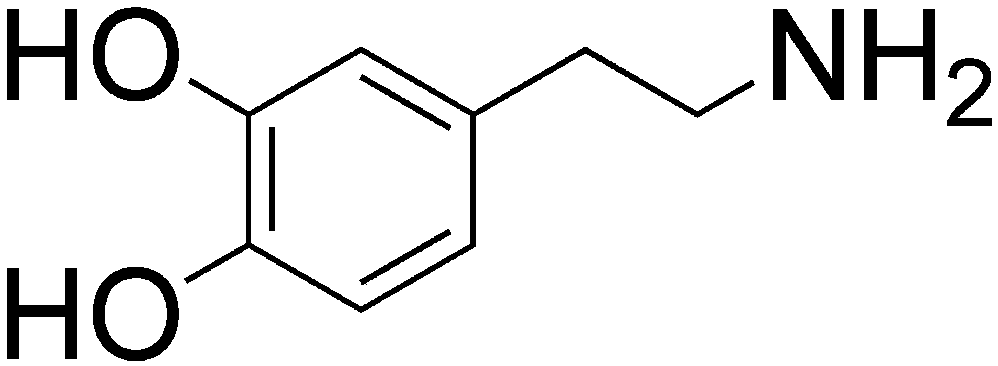

[0035] Step 1: take 1.2g of Tris (Tris) and dissolve it in 1000ml of deionized water, then add hydrochloric acid dropwise to prepare a buffer solution with a pH value of 8.5, then add 2g of dopamine to the buffer solution, Stir evenly at a speed of 400 rpm. Add 500 mg of graphene after ultrasonic dispersion, start the self-polymerization reaction, time it, and finish the reaction after 6 hours. Wash with deionized water, suction filter, and vacuum-dry in a 50°C oven; after that, weigh 500mg of modified graphene filler, add it to 500ml of silver nitrate solution with a concentration of 0.1mol / L, stir evenly at a speed of 400rpm, and start Timing, the reaction ends after 6h. Washing with deionized water, suction filtration, and vacuum drying in an oven at 50°C can obtain a bionic point-surface thermal conductivity enhancing filler in the present invention.

[0036]Step 2: Weigh 0.5g of the thermally conductive enhancing filler prepared in step 1, add it to ethyl acetate, dispe...

Embodiment 2

[0040] Step 1: take 1.2g of Tris (Tris) and dissolve it in 1000ml of deionized water, then add hydrochloric acid dropwise to prepare a buffer solution with a pH value of 8.5, then add 2g of dopamine to the buffer solution, Stir evenly at a speed of 400 rpm. Add 1 g of graphene nanosheets after ultrasonic dispersion, start the self-polymerization reaction, time it, and finish the reaction after 6 hours. Wash with deionized water, suction filter, and vacuum-dry in a 50°C oven; after that, weigh 1g of modified graphene nanosheets, add them to 500ml of silver ammonia solution with a concentration of 0.1mol / L, and then add 0.1g of stabilizer poly Vinylpyrrolidone was stirred evenly at a speed of 400rpm, the timing was started, and the reaction was finished after 6h. Washing with deionized water, suction filtration, and vacuum drying in an oven at 50°C can obtain a bionic point-surface thermal conductivity enhancing filler in the present invention.

[0041] Step 2: Weigh 1g of the...

Embodiment 3

[0044] Step 1: take 1.2g of Tris (Tris) and dissolve it in 1000ml of deionized water, then add hydrochloric acid dropwise to prepare a buffer solution with a pH value of 8.5, then add 4g of dopamine to the buffer solution, Stir evenly at a speed of 400 rpm. Add 1 g of boron nitride nanosheets dispersed by ultrasonic to start the self-polymerization reaction, time it, and finish the reaction after 4 hours. Wash with deionized water, filter with suction, and dry in a vacuum oven at 50°C; after that, weigh 1g of modified boron nitride nanosheets and add to 500ml of HAuCl chloroaurate with a concentration of 0.05mol / L 4 In the solution, stir evenly at a speed of 400 rpm, start timing, and end the reaction after 6 hours. Washing with deionized water, suction filtration, and vacuum drying in an oven at 50°C can obtain a bionic point-surface thermal conductivity enhancing filler in the present invention.

[0045] Step 2: Weigh 1g of the thermally conductive enhancing filler prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com