White ink for composite reinforcing material and preparation method of white ink

A technology for reinforcing materials and inks, which is applied in the field of white ink for composite reinforcing materials and its preparation, can solve problems such as high solid content and low viscosity, achieve good mechanical properties, improve scratch resistance, and enhance decolorization ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

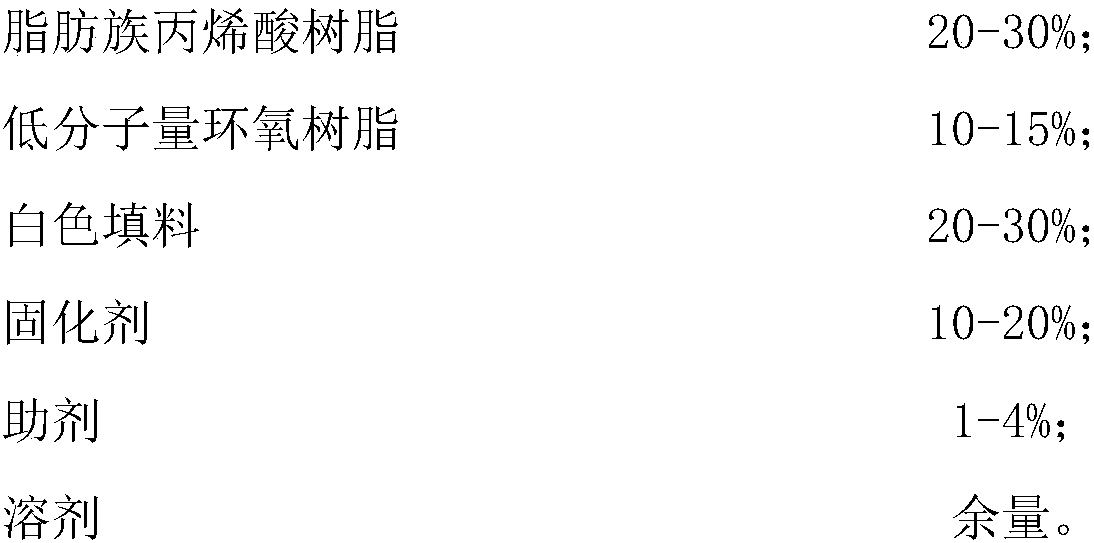

[0025] A kind of white ink for composite reinforcing material comprises following weight ratio composition:

[0026]

[0027] A preparation method of white ink for composite reinforcing material, the specific steps are as follows:

[0028] 1) Mother liquor configuration: Weigh each component according to the formula content, add 25% by weight aliphatic acrylic resin into the solvent, stir until the aliphatic acrylic resin dissolves, then add 1 / 10 of curing agent N75, Stir at a high speed of 1600r / min for pre-curing for 10 minutes, then add 12% low molecular weight epoxy resin, stir and mix evenly until the epoxy resin is completely dissolved to obtain a mother liquor;

[0029] 2) Ink synthesis: Add white filler with a particle size of 300 mesh and 1.5% BKY011 auxiliary agent mixed with titanium dioxide and talcum powder with a mass ratio of 2:1 to the mother liquor, stir and mix evenly at a speed of 2000r / min, and finally Add the remaining amount of curing agent N75, and c...

Embodiment 2

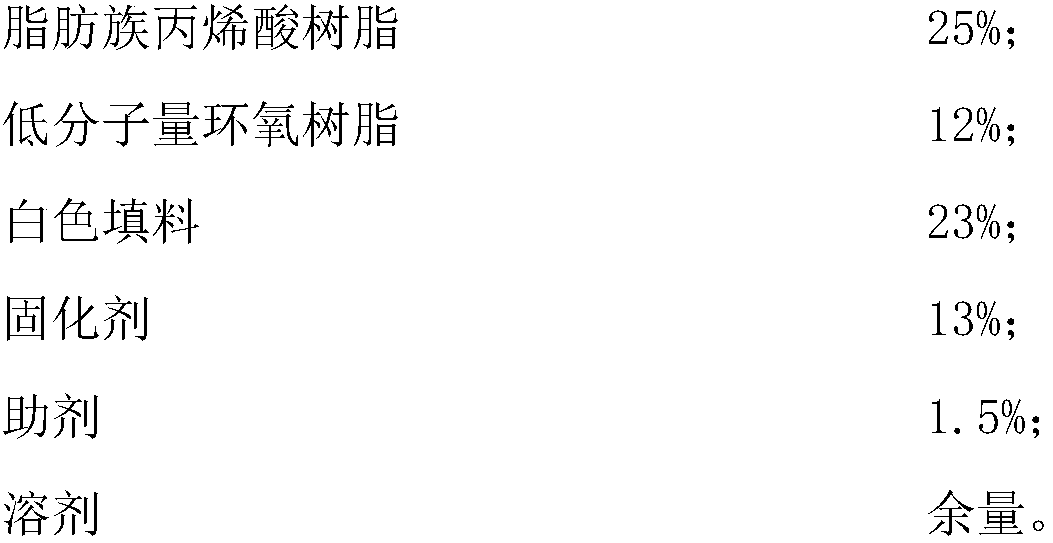

[0031] The preparation method of the white ink for composite reinforcing material in this embodiment is the same as that in Example 1, the difference is that a white ink for composite reinforcing material includes the following weight ratio components:

[0032]

Embodiment 3

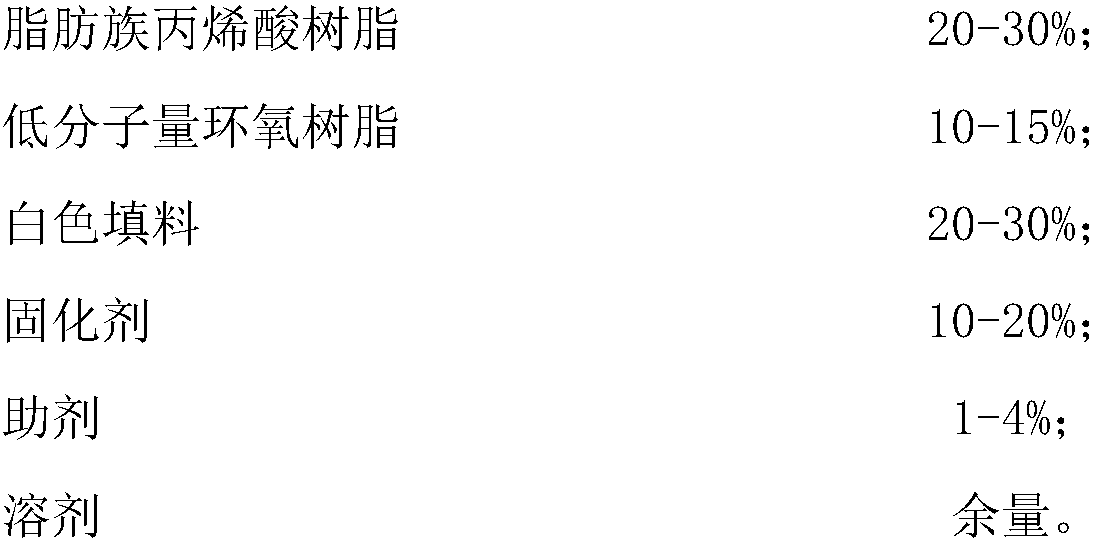

[0034] The preparation method of the white ink for composite reinforcing material in this embodiment is the same as that in Example 1, the difference is that a white ink for composite reinforcing material includes the following weight ratio components:

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com