Microporous PVC foam and preparation method thereof

A foam and microporous technology, applied in the field of PVC foam, can solve the problems of limited development, poor mechanical properties and strength, and achieve the effects of facilitating construction, high production efficiency, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

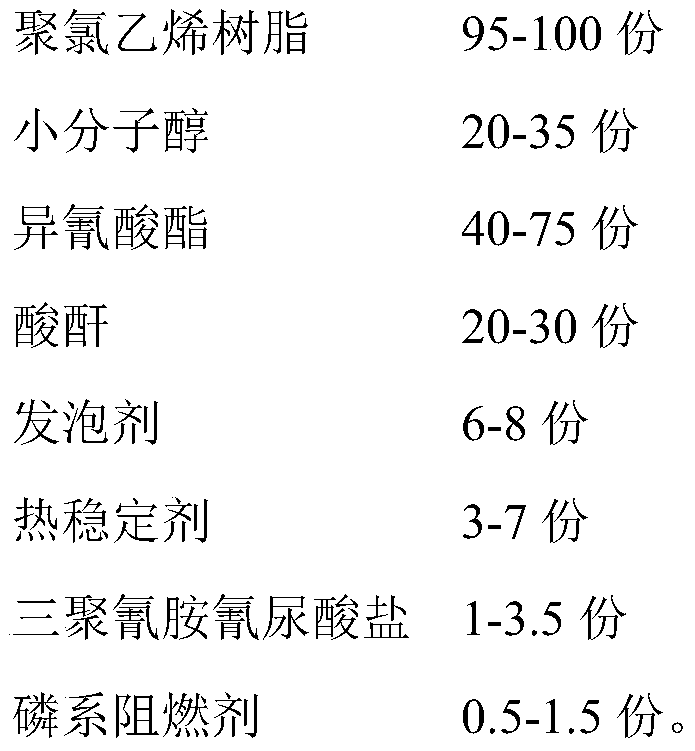

[0028] The microporous PVC foam described in the present embodiment 1, in parts by weight, has a raw material composition as follows:

[0029]

[0030]

[0031] in:

[0032] The viscosity of polyvinyl chloride resin at room temperature is 5000-6000mPa·s.

[0033] Small molecule alcohol is a mixture of ethanol and tert-butanol.

[0034] The isocyanate is a mixture of toluene diisocyanate and carbodiimide-modified diphenylmethane diisocyanate.

[0035] The anhydride is a mixture of phthalic anhydride, maleic anhydride and cyclohexane-1,2-dicarboxylic anhydride.

[0036] The blowing agent is a mixture of diisopropyl azodicarboxylate and 4,4'-oxobisbenzenesulfonyl hydrazide; among them, diisopropyl azodicarboxylate and 4,4'-oxobisbenzenesulfonyl The mass ratio of hydrazine is 2:2.5.

[0037] The heat stabilizer is a mixture of carbon-4,4-diisoidene-alcohol-phosphate chelating polymer and organotin 181.

[0038] The phosphorus-based flame retardant is tricresyl phosphate...

Embodiment 2

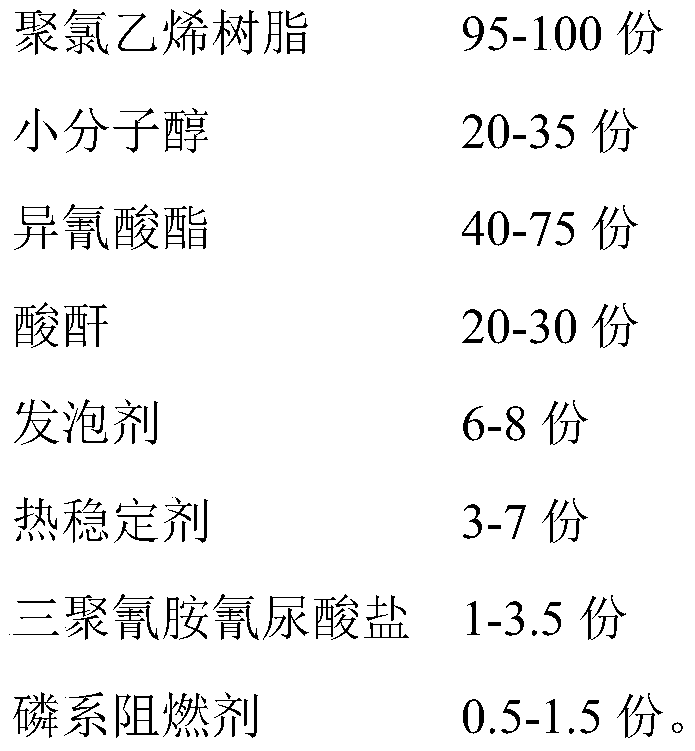

[0045] The microporous PVC foam described in the present embodiment 2, in parts by weight, has a raw material composition as follows:

[0046]

[0047]

[0048] in:

[0049] The viscosity of polyvinyl chloride resin at room temperature is 7000-8000mPa·s.

[0050] The small molecule alcohol is methanol.

[0051] The isocyanate is cyclohexyl diisocyanate.

[0052] The anhydride is a mixture of trimellitic anhydride, hexachloromethenetetrahydrophthalic anhydride and methylhexahydrophthalic anhydride.

[0053] The blowing agent is a mixture of diisopropyl azodicarboxylate and 4,4'-oxobisbenzenesulfonyl hydrazide; among them, diisopropyl azodicarboxylate and 4,4'-oxobisbenzenesulfonyl The mass ratio of hydrazine is 3:4.5.

[0054] The heat stabilizer is a mixture of carbon-4,4-diisoidene-alcohol-phosphate chelating polymer and organotin 181.

[0055] The phosphorus-based flame retardant is a mixture of tert-butylated triphenyl phosphate and methacryloyloxyethyl phosphate...

Embodiment 3

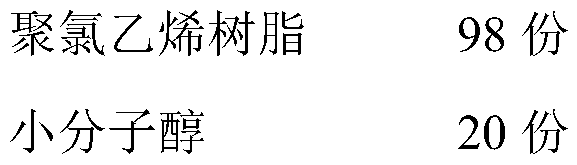

[0062] The microporous PVC foam described in the present embodiment 3, in parts by weight, has a raw material composition as follows:

[0063]

[0064] in:

[0065] The viscosity of polyvinyl chloride resin at room temperature is 7500-8000mPa·s.

[0066] The small molecule alcohol is tert-butanol.

[0067] The isocyanate is diphenylmethane diisocyanate.

[0068] The anhydride is a mixture of trimellitic anhydride and cyclohexane-1,2-dicarboxylic anhydride.

[0069] The blowing agent is a mixture of diisopropyl azodicarboxylate and 4,4'-oxobisbenzenesulfonyl hydrazide; among them, diisopropyl azodicarboxylate and 4,4'-oxobisbenzenesulfonyl The mass ratio of hydrazine is 2.5:4.0.

[0070]The heat stabilizer is a mixture of carbon-4,4-diisoidene-alcohol-phosphate chelating polymer and organotin 181.

[0071] The phosphorus-based flame retardant is a mixture of tricresyl phosphate and tert-butylated triphenyl phosphate.

[0072] The preparation method of the microporous P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com