Liquid crystal flame-retardant foam material and preparation method thereof

A foaming material, liquid crystal technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of environmental pollution, easy decomposition and attenuation of organic flame retardants, and achieve wide applicability, excellent flame retardant performance, and preparation technology. Energy efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of Liquid Crystal Polyester Flame Retardant Foaming Material

[0040] Add 16.02g 1,6-naphthalenediol, 21.62g 2,7-naphthalene dicarboxylic acid, 21.42g4'-hydroxybiphenyl-3-carboxylic acid, 3.84g N-(4- Carboxyphenyl)-4-phenylethynylphthalimide, 4.02g N-(4-acetate phenolic ester)-4-phenylethynylphthalimide, 50mL acetic anhydride and 2mg di Butyl tin oxide. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. Nitrogen flow was introduced, and the acetylation reaction was carried out at a temperature of 130° C. for 45 minutes. The reaction mixture was heated in a quicksand bath at a heating rate of 1.0°C / min, and the reaction temperature rose from 130°C to 280°C. After the reaction is completed, an opaque melt is obtained, which is cooled to room temperature, and the product is removed from the flask, and then ground into a fine powder, which is a liquid crystal polyester powder. The obta...

Embodiment 2

[0041] Example 2 Preparation of liquid crystal polyester imide flame retardant foaming material

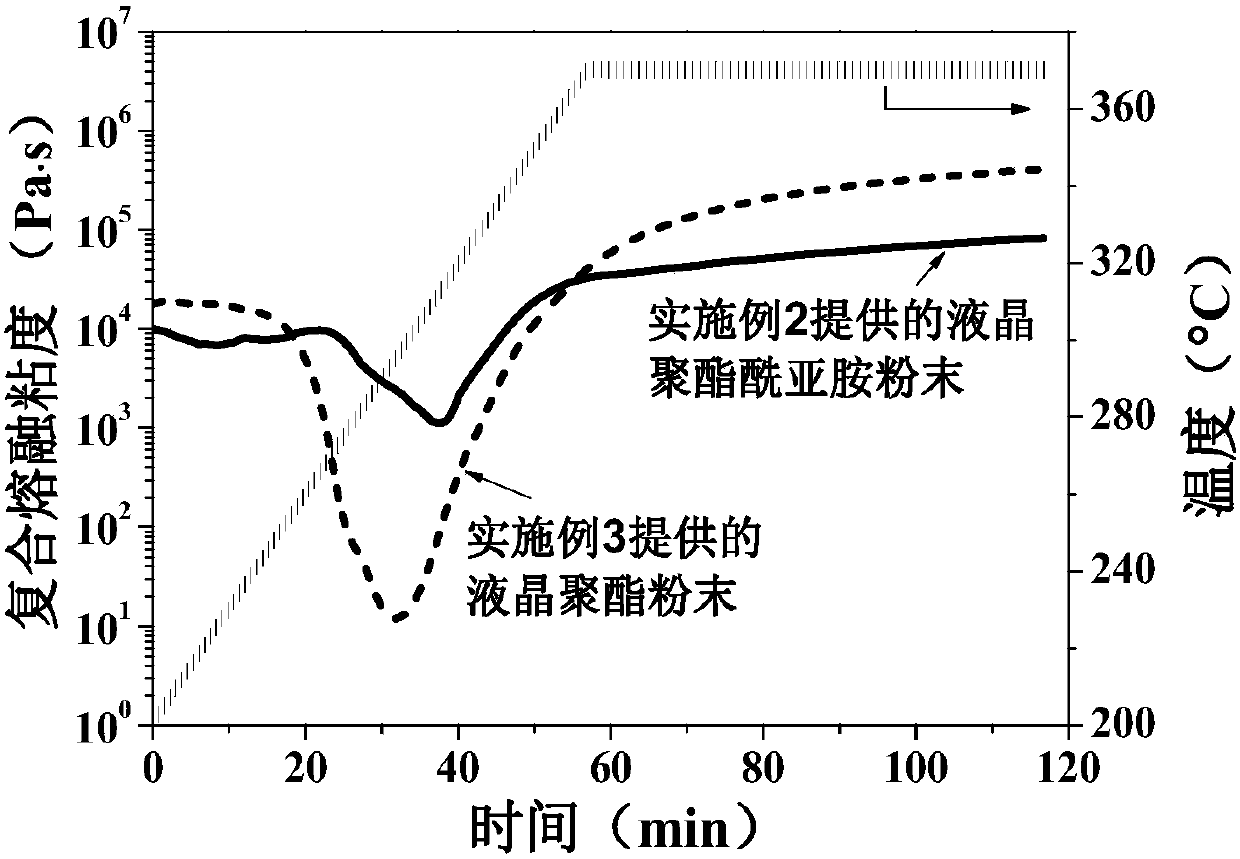

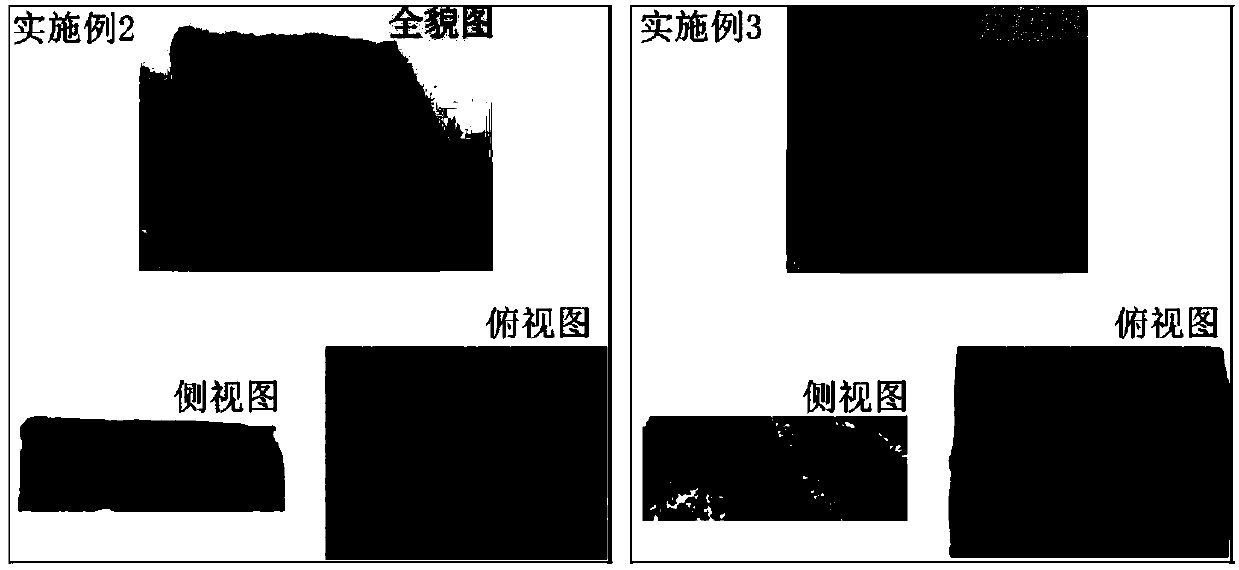

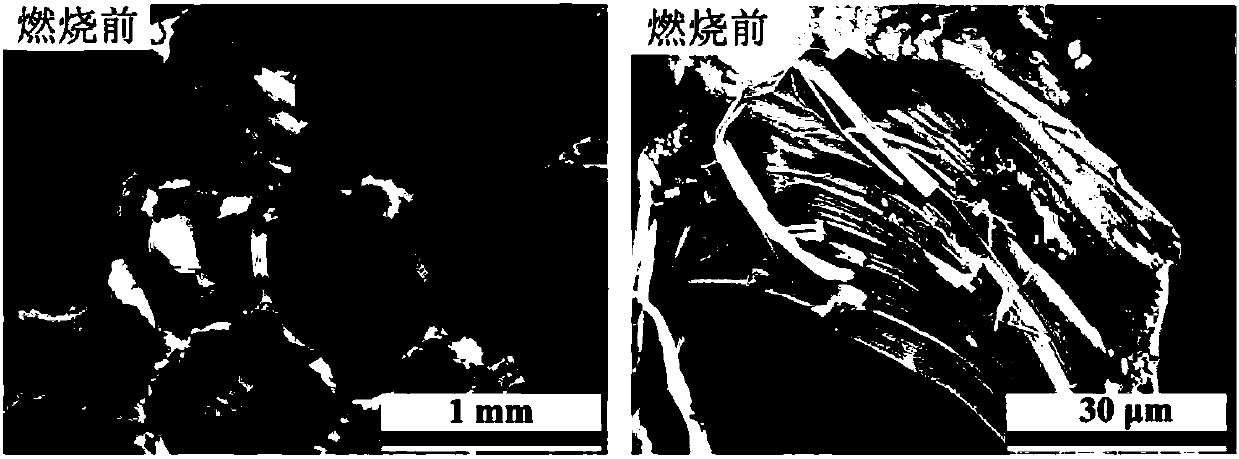

[0042] Add 93.10g 1,3-resorcinol, 83.08g 1,3-isophthalic acid, 39.16g N-(3'-hydroxyphenyl) trimellitimide, 41.01g N-(3-Carboxyphenyl)-4-phenylethynylphthalimide, 42.59g N-(3-Acetoxyphenyl)-4-phenylethynylphthalimide , 300mL acetic anhydride and 25mg sodium acetate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the acetylation reaction was carried out at a temperature of 120° C. for 60 minutes. The reaction mixture was heated in a quicksand bath at a heating rate of 0.5°C / min, and the reaction temperature rose from 120°C to 325°C. At the end of the reaction, an opaque melt was obtained. After cooling to room temperature, the product was removed from the flask, and then ground into a fine powder. The complex viscosity-time curve of its powder sample is heated from 20...

Embodiment 3

[0044] Example 3 Preparation of Liquid Crystal Polyester Flame Retardant Foaming Material

[0045] Add 37.24g 1,4-hydroquinone, 33.23g 1,4-terephthalic acid, 69.06g 3-hydroxybenzoic acid, 18.82g 7-hydroxy-2-naphthoic acid, 27.34g N-(4-Carboxyphenyl)-4-phenylethynylphthalimide, 28.39g N-(4-Phenylacetate)-4-phenylethynylphthalimide , 150mL acetic anhydride and 10mg potassium acetate. The flask was fitted with a sealed glass paddle stirrer, a nitrogen inlet tube and an insulated distillation head. A moderate nitrogen flow was introduced, and the acetylation reaction was carried out at a temperature of 140° C. for 30 minutes. The reaction mixture was heated in a quicksand bath at a heating rate of 1.0°C / min, and the reaction temperature rose from 140°C to 310°C. At the end of the reaction, an opaque melt was obtained. After cooling to room temperature, the product was removed from the flask, and then ground into a fine powder. The complex viscosity-time curve of its powder sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com