Plant fiber enhanced wet-mixed mortar and preparation method thereof

A plant fiber and wet-mixed mortar technology, which is applied in the field of wet-mixed mortar production, can solve the problems of affecting the fluidity of wet-mixed mortar, insignificant improvement in mechanical properties, poor bonding performance, etc. The effect of mining and improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

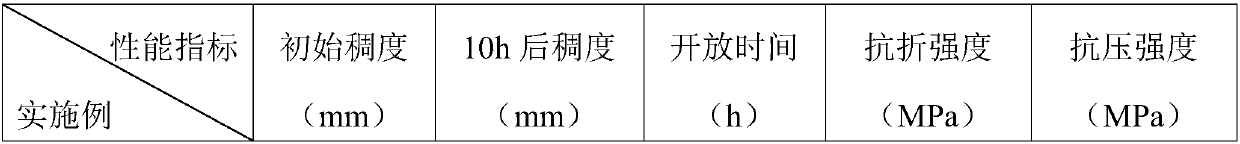

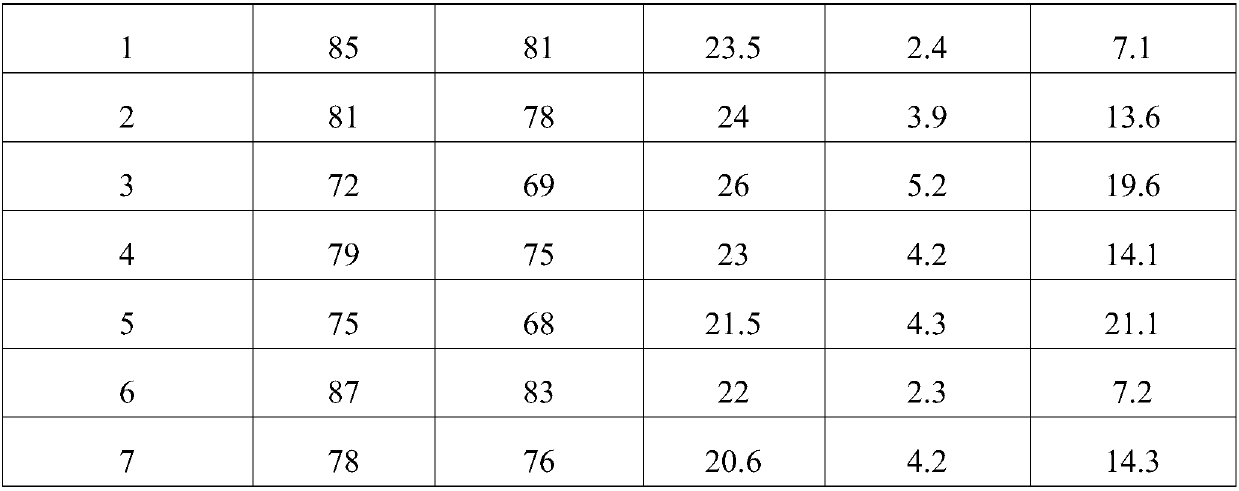

Embodiment 1

[0028] In this example, a plant fiber-reinforced wet-mix mortar with a strength grade of M5 is prepared, which is made of the following raw materials in parts by weight: cement 100kg, composite mineral admixture 22kg, sand 710kg, mortar stabilizer 4.1kg, mortar adjustment The weight of the cement is 0.15kg, plant fiber 0.09kg, and water is 121kg; the cement is Portland cement; the strength grade of the Portland cement is 42.5Mpa; the composite mineral admixture is mixed with the following parts by weight After stirring for 10 minutes to 30 minutes, it is prepared: 19.8kg of grade II fly ash, 1.76kg of grade S95 mineral powder, 0.4kg of limestone powder, and 0.044kg of gypsum; the sand is made by mixing ultra-fine sand and machine-made sand in a weight ratio of 1:4 The ultra-fine sand has a particle size of less than 4.75mm, a fineness modulus of 0.9, a machine-made sand particle size of less than 4.75mm, and a coefficient modulus of 3.0; the plant fiber is a wheat straw fiber pr...

Embodiment 2

[0035] In this embodiment, a plant fiber-reinforced wet-mix mortar with a strength grade of M10 is prepared, which is made of the following raw materials by weight: 100kg of cement, 38kg of composite mineral admixture, 680kg of sand, 4.6kg of mortar stabilizer, and mortar adjustment The weight of the slag cement is 0.12kg, the plant fiber is 0.15kg, and the water is 128kg; the cement is Portland slag cement; the strength grade of the Portland slag cement is 32.5Mpa; the composite mineral admixture consists of the following parts by weight After mixing the raw materials, stir for 10min~30min to prepare: Ⅱ grade fly ash 32.68kg, S95 grade ore powder 3.42kg, microbeads 0.38kg, limestone powder 1.52kg; the sand is made of ultra-fine sand and machine-made sand in a weight ratio of 1: 3.2 Mixed production; the particle size of the ultra-fine sand is less than 4.75mm, and the fineness modulus is 0.8; the particle size of the machine-made sand is less than 4.75mm, and the coefficient mo...

Embodiment 3

[0042] In this example, a plant fiber-reinforced wet-mix mortar with a strength grade of M15 is prepared, which is made of the following raw materials in parts by weight: cement 100kg, composite mineral admixture 51kg, sand 660kg, mortar stabilizer 5.3kg, mortar adjustment The weight of the cement is 0.11kg, plant fiber is 0.18kg, and the weight of water is 137kg; the cement is fly ash Portland cement; the strength grade of the fly ash Portland cement is 32.5Mpa; the composite mineral admixture is composed of The following parts by weight of the raw materials are mixed and stirred for 10 minutes to 30 minutes to prepare: Ⅱ grade fly ash 43.85kg, S95 grade mineral powder 4.08kg, silica fume 2.55kg, limestone powder 1.02kg; the sand is made of ultra-fine sand and machine-made sand The weight ratio is 1:1.5; the particle size of the ultra-fine sand is less than 4.75mm, and the fineness modulus is 1.1; the particle size of the machine-made sand is less than 4.75mm, and the coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com