Inorganic surface treatment galvanized steel plate and preparation method thereof

A galvanized steel sheet and surface treatment technology, applied in the coating process of metal materials, etc., can solve the problems of lack of surface conductivity and high requirements for production equipment, and achieve the effect of excellent anti-red rust performance and surface conductivity of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0200] (1) Substrate

[0201] The types of substrates used are shown in Table 1. Mild steel with a plate thickness of 0.5 mm was used as the substrate on which the inorganic film was applied. The substrates in Table 1 were sprayed and cleaned with an aqueous solution of an alkaline degreasing agent (brand: FC-364S, produced by Shanghai Parker Sejing) with a mass fraction of 2%. Aqueous solution temperature: 50°C; spraying time: 60 seconds. Then wash it with industrial pure water to remove the residual alkaline components on the surface, and dry it with a hair dryer for later use.

[0202] Table 1 Substrate

[0203]

[0204]

[0205] (2) Water-based inorganic surface treatment agent

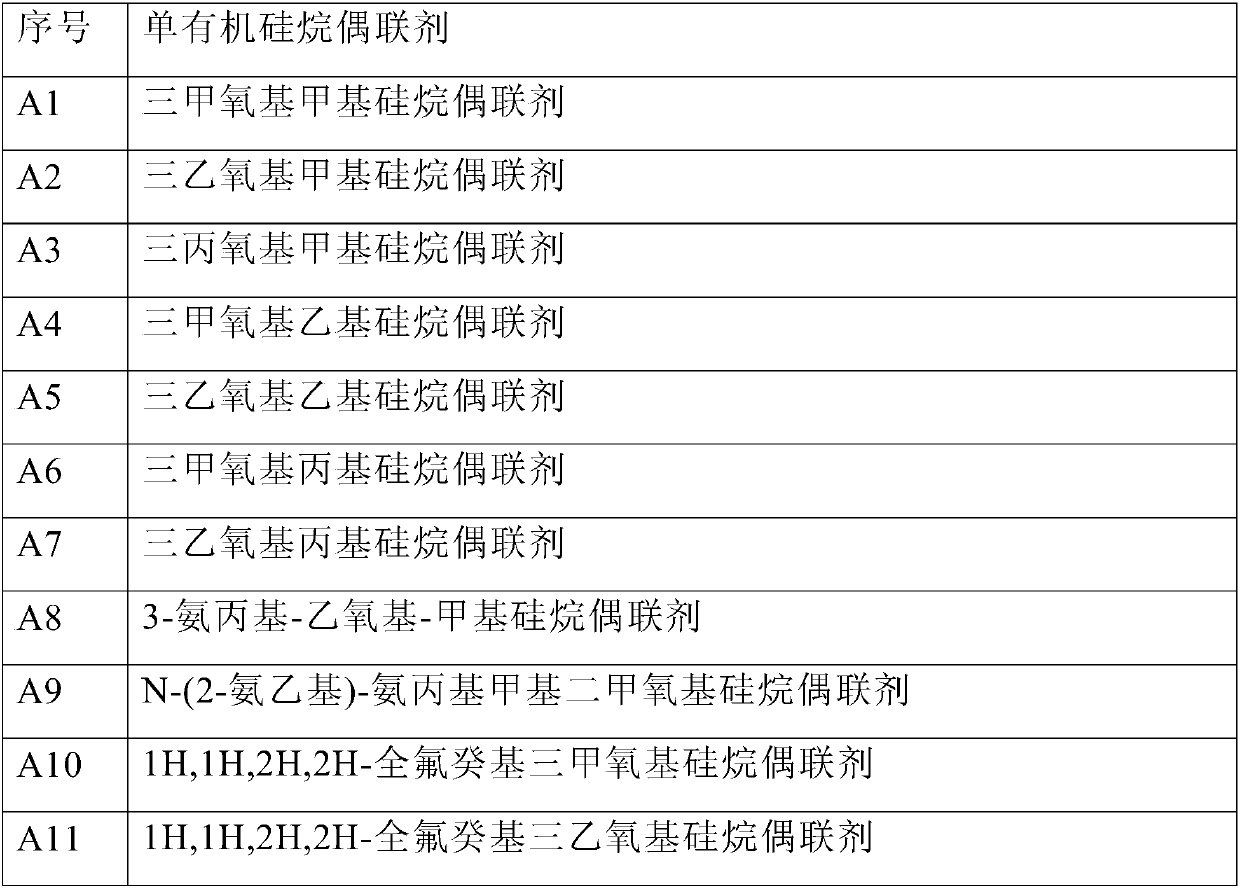

[0206] The water-based inorganic surface treatment agent used to form the inorganic film is a combination of hydrophobic monoorganosilane coupling agent (Table 2), system crosslinking agent (Table 3), water-soluble nano-sol (Table 4), surface-modified high-density polymer Ethylene parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com